UV viscosity-reducing adhesive and preparation method thereof

A viscose, pentylene glycol copolyester technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of low peel strength, high peel strength, inability to fix and easily pick up and other problems, to achieve the effect of fast reaction rate, improvement of the brittleness of the rubber layer, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

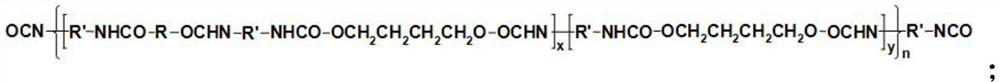

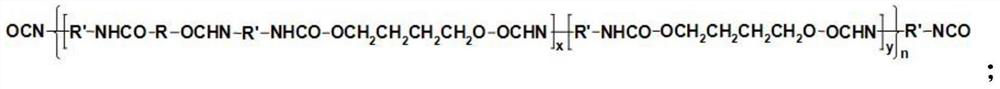

[0030] The present invention provides a kind of preparation method of UV viscosifying adhesive, comprising the following steps:

[0031] S1 Weigh fumaryl chloride and pentylene glycol monomers and dissolve them in solvent A, add triethylamine and pass through nitrogen to react at 25-35°C for 3-5 hours, after the reaction is completed, take the liquid phase after centrifugation, add n-hexane for precipitation Obtain hydroxyl-terminated fumaryl chloride-pentanediol copolyester;

[0032] S2 Weigh the hydroxyl-terminated fumaryl chloride-pentanediol copolyester, isophorone diisocyanate monomer, catalyst and solvent B in a container, feed nitrogen gas at 60-80°C for 3-5 hours, and then add The chain agent is reacted at 60-80°C for 2-3 hours, and after the reaction is completed, a photoinitiator is added and stirred to obtain a UV viscose-reducing adhesive.

[0033] In a specific embodiment, in step S1, solvent A is, for example, one or more of tetrahydrofuran, toluene, and dichlor...

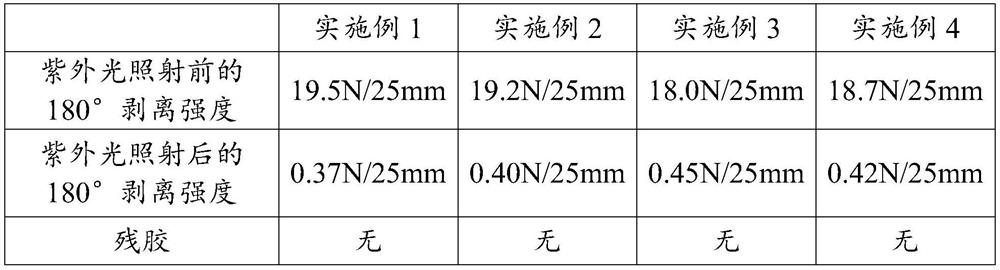

Embodiment 1

[0046] A kind of UV viscosity-reducing adhesive, the preparation method is as follows:

[0047] (1) Preparation of hydroxyl-terminated fumaryl chloride-pentanediol copolyester

[0048] Weigh 47g (0.45mol) of pentanediol and 71g of triethylamine, dissolve them in 210g of tetrahydrofuran, stir and slowly add 54g (0.35mol) of fumaryl chloride dropwise. After the dropwise addition, the condensation polymerization reaction was carried out at 30° C. for 3 h under the protection of nitrogen, and then the reaction mixture was cooled to room temperature, and the solution phase was collected by centrifugation. Add 260g of n-hexane to the solution phase to precipitate and filter, then wash the precipitate with 100g deionized and 100g ethanol in sequence, and dry the washed precipitate in a vacuum oven at 50°C for 12h to obtain terminal hydroxyl fumaryl chloride - Pentylene glycol copolyester. The obtained hydroxyl-terminated fumaryl chloride-pentanediol copolyester had a hydroxyl value...

Embodiment 2

[0052] A kind of UV viscosity-reducing adhesive, the preparation method is as follows:

[0053] (1) Preparation of hydroxyl-terminated fumaryl chloride-pentanediol copolyester

[0054] Weigh 45g (0.43mol) of pentanediol and 75g of triethylamine, dissolve in 215g of tetrahydrofuran, stir and slowly add 55g (0.36mol) of fumaryl chloride dropwise. After the dropwise addition, the condensation polymerization reaction was carried out at 30° C. for 3 h under the protection of nitrogen, and then the reaction mixture was cooled to room temperature, and the solution phase was collected by centrifugation. Add 260g of n-hexane to the solution phase to precipitate and filter, then wash the precipitate with 100g deionized and 100g ethanol in sequence, and dry the washed precipitate in a vacuum oven at 50°C for 12h to obtain terminal hydroxyl fumaryl chloride - Pentylene glycol copolyester. The obtained hydroxyl-terminated fumaryl chloride-pentanediol copolyester had a hydroxyl value of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com