Second-order hot-mixing epoxy adhesive layer oil special for steel bridge deck pavement as well as preparation method and application of special second-order hot-mixing epoxy adhesive layer oil

A technology of epoxy adhesive layer oil and steel bridge deck, which is applied in the direction of epoxy resin coatings, coatings, bridges, etc., can solve the problems of insufficient bonding strength, insufficient durability, and insufficient waterproof performance of epoxy adhesive layers, and achieve Improve epoxy flexibility, excellent shear resistance, and controllable working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

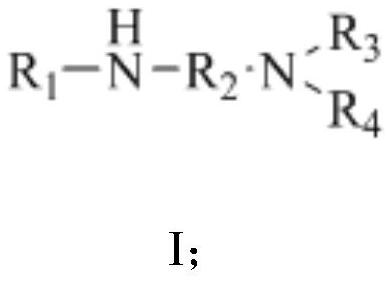

[0032] Preparation of high temperature epoxy curing agent:

[0033] 1mol of dodecyl primary amine, 1.2mol of 2-chloroethylamine and 50ml of ethanol constitute a reaction system, react at 50°C for 7.5h under the catalysis of sodium ethoxide, and obtain a second-stage hot-mix epoxy high-temperature curing agent;

[0034] Hot mix epoxy resin preparation:

[0035] Described epoxy resin A proportioning:

[0036]

[0037] Described resin B component comprises following weight components:

[0038] 45 parts of self-made high temperature curing agent

[0039] T-99 strong elastic toughness epoxy curing agent 30 parts

[0040] Mix epoxy resin component A and resin component B according to the above ratio at a weight ratio of 2:1, and form a test piece after mixing. The test piece is kept in an oven at 60°C for 4 days and then placed at 23°C for 1 day to test the heat. The basic performance of mixing epoxy resin, the coating amount of epoxy resin is 0.46kg / m 2 .

[0041] Comparat...

Embodiment 2

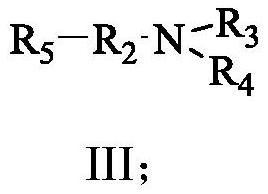

[0046] Preparation of high temperature epoxy curing agent:

[0047] 1 mol of tetradecyl primary amine, 50 ml of cyclohexane and 2 mol of 3-chloropropylamine constitute a reaction system, and react for 6 hours under the catalysis of sodium ethoxide at 40°C to prepare a second-stage hot-mix epoxy high-temperature curing agent.

[0048] Hot mix epoxy resin preparation:

[0049] Described epoxy resin A proportioning:

[0050]

[0051] Described resin B component comprises following weight components:

[0052] 60 parts of self-made high temperature curing agent

[0053] Polyetheramine D-230 40 parts

[0054] Mix the epoxy resin component A and the resin component B according to the weight ratio of 1:1, and form the test piece after mixing. After the test piece is kept in a 60°C oven for 4 days, it is placed at 23°C for 1 day to test the hot mix epoxy resin. The basic properties of the resin, the coating amount of epoxy resin is 0.7kg / m 2 .

[0055] Comparative example experi...

Embodiment 3

[0060] Preparation of high temperature epoxy curing agent:

[0061] 1 mol of hexadecyl primary amine, 50 ml of tetrahydrofuran and 1 mol of 2-chloromethylethylamine constitute a reaction system, and react for 8 hours under the catalysis of sodium ethoxide at 65°C. Prepare a second-order hot-mix epoxy high-temperature curing agent;

[0062] Hot mix epoxy resin preparation:

[0063] Described epoxy resin A proportioning:

[0064]

[0065] Described resin B component comprises following weight components:

[0066] 63 parts of self-made high temperature curing agent

[0067] Polyetheramine D-400 27 parts

[0068] Mix the epoxy resin component A and the resin B component according to the weight ratio of 3:1, and form the test piece after mixing. After the test piece is cured in the oven at 60 ℃ for 4 days, the temperature is 23 ℃ for 1 day to test the hot mix epoxy The basic properties of the resin, the coating amount of epoxy resin is 0.8kg / m 2 .

[0069] Comparative exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com