Radiation refrigeration thin film material based on indium oxide nanocrystalline doping and preparation method thereof

A technology for radiation refrigeration and thin film materials, applied in the field of radiation refrigeration thin film materials and their preparation, can solve the problems of difficult to achieve full coverage, inability to enhance coverage, sharp absorption peaks, etc., and achieve good regional adaptability, low cost, and low preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

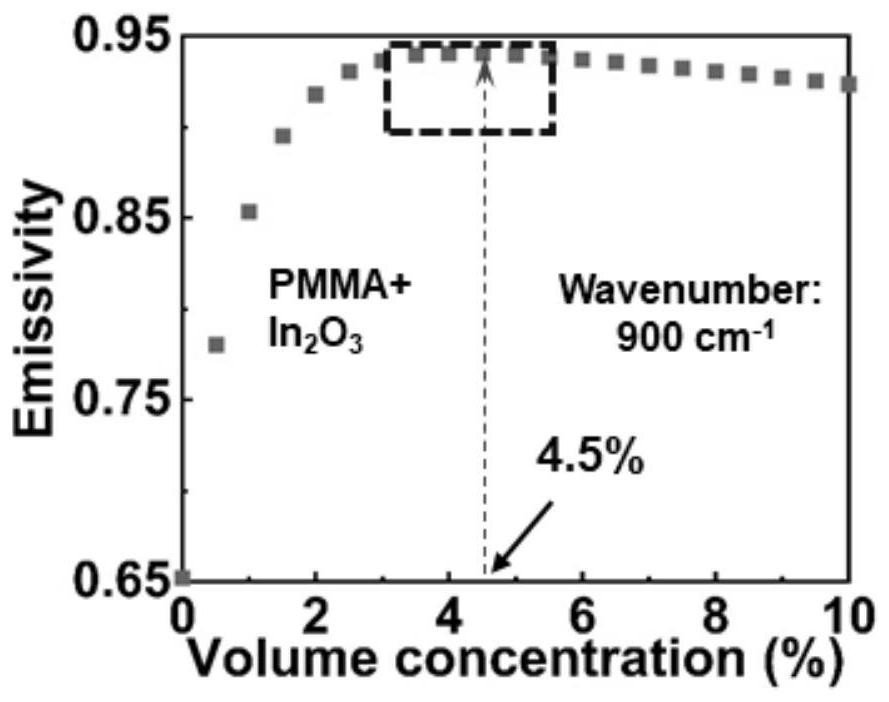

[0028] This embodiment provides nanocrystals doped indium oxide-based radiation cooling film material according to mole percent, comprising the following components: 0.5 to 15% tin, indium oxide crystal 85 to 99.5%;

[0029] According to which the volume fraction thereof, comprising the following components: tin-doped indium oxide crystal 3 to 5%, polymethyl methacrylate (poly methyl methacrylate, PMMA) 95 ~ 97%;

[0030] A mass percentage thereof, comprising the following components: tin-doped indium oxide crystal 16-24%, PMMA76-24%.

[0031] Indium oxide prepared by the invention is finished nanocrystalline direct band gap semiconductor, band gap of about 3.7eV, X-ray diffraction main diffraction peaks at 21.2 °, 30.4 °, 35.5 °, 37.5 °, 41.8 °, 45.6 °, 51.1 °, 56 °, 60.6 °.

Embodiment 2

[0033] The present embodiment provides a method for preparing nanocrystals doped indium oxide thin film material based on radiant cooler, comprising the steps of:

[0034] Indium acetate powder (1) 1mmol and dispersed in 10ml of n-octyl ether solution, then add 2-ethylhexanoate stannous 0.2mmol of n-octanoic acid and 3.6mmol 10mmol oleylamine, and indium acetate suspension was added to a three-neck flask together, while heating to 80 deg.] C with nitrogen purge and at 600r / min was stirred for 30min, indium acetate until the powder was completely dissolved, then the solution became clear and transparent. Under a nitrogen atmosphere and then the solution was heated to 150 deg.] C, heated and stirred sufficiently, and then heated to 280 deg.] C and stirred sufficiently; end of the reaction the final dark green solution was obtained, cooled to room temperature, ethyl acetate was added to the resulting product was purified by centrifugation to remove the supernatant after the speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com