A laser cutting head with variable spot track shape and its cutting process

A technology of laser cutting head and cutting process, which is applied in the field of cutting process and laser cutting head, which can solve the limitations of cutting speed, cutting thickness and cutting surface, cannot realize the change of direction in the plane, and cannot meet the requirements of wider kerf To achieve the effect of ensuring long-term operation, improving energy utilization and cutting efficiency, and increasing plate thickness and cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

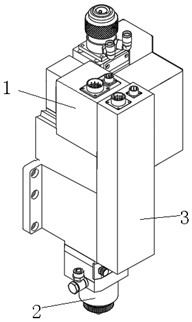

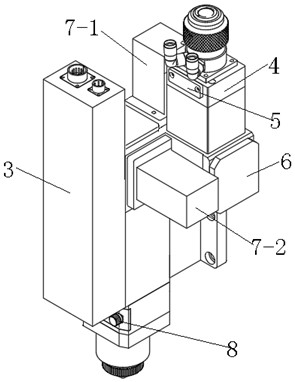

[0055] Such as Figure 2-6 As shown, a laser cutting head with variable spot trajectory shape includes a beam shaper 4, a trajectory control component, a focusing component and a nozzle arranged in sequence along the optical path direction, and the beam shaper 4 includes a beam filter component and a collimating lens component, In the direction of the light path, the beam filter assembly is positioned in front of the collimator assembly, the beam shaper 4 is equipped with an upper protective mirror 5, and the upper protection mirror 5 is located between the beam filter assembly and the collimator assembly, and the external device of the track control assembly There is a sheet metal housing 1 .

[0056] The middle part of the beam filtering component is provided with a beam passing hole, and a conical beam absorbing surface is arranged above the beam passing hole. The tapered beam absorption surface can be set according to the requirements. Through this setting, the high-ener...

Embodiment 2

[0070] The structure of the laser head of this embodiment is basically the same as that of Embodiment 1, the difference is that in the track control assembly of this embodiment, in the direction of the optical path, the Y-axis vibrating mirror 705-2 is located in front of the X-axis vibrating mirror 705-1, The reflector 6 is located behind the X-axis vibrating mirror 705-1, and the reflective surface of the reflector 6 is inclined downward;

[0071] Based on this setting, the optical path structure in this embodiment is as follows Figure 10 As shown, the laser beam emitted by the laser source passes through the beam filter assembly to filter out the stray light of the optical fiber, and then enters the collimator assembly through the upper protective mirror. The collimator 11 shapes the diffused beam into a parallel beam, and the beam hits the Y On the oscillating mirror 705-2, the Y-axis galvanometer 705-2 is reflected to the X-axis galvanometer 705-1, and the X-axis galvano...

Embodiment 3

[0073] It is suitable for laser cutting machines where the optical fiber interface of the laser source is set horizontally. No reflector is provided in the trajectory control component of this embodiment, and the optical fiber interface is inserted horizontally into the beam shaper. In this embodiment, the optical path is as follows Figure 11 As shown, the beam processed by the beam shaper at this time is directly projected on the X-axis galvanometer 705-1, reflected by the X-axis galvanometer 705-1 to the Y-axis galvanometer 705-2, and then focused by the focusing mirror 15 and The cutting laser is output from the nozzle through the lower protective mirror 8, and the control principle of the spot track is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com