Dental implant with nano antibacterial structure ring at gingival penetrating part and processing method of dental implant

A technology for dental implants and a processing method, applied in the field of oral implants, can solve the problems that the technology cannot meet the production control, sterilization and long-term preservation of medical devices, the chemical coating cannot maintain the efficacy for a long time, and periodontitis accelerates gingival implants. To reduce the risk of periodontal infection, promote adhesion, and inhibit adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, the plasma implantation and femtosecond laser processing methods were used to prepare the antibacterial bioactive surface on the surface of the implant transgingival part.

[0023] The specific steps and processes are:

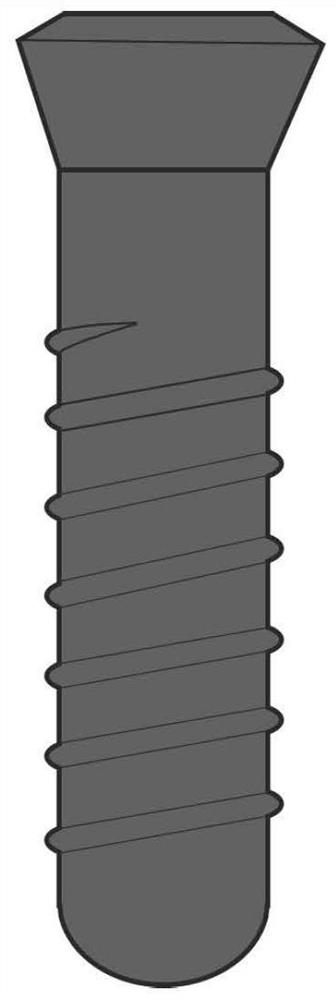

[0024] (1) Firstly, C, N, Ca, and P elements were injected into the surface of the implant by plasma injection method. The pure Ti implant was placed in an atmosphere containing C, N, Ca, and P, and the composition containing the above four elements was prepared from the implant surface to a depth of 500nm from the surface by using metal plasma immersion implantation technology. layer. Figure 1a Schematic diagram of the implant. Figure 1b It is a schematic diagram of the parts treated by the plasma injection method, and the dark part is the plasma injection area.

[0025] (2) Measure the size of the implant and the size of the processing position. The length of the implant used in this example is 8 mm, the length of the gingival pa...

Embodiment 2

[0045] In this example, femtosecond laser processing was used twice to obtain the desired structure at the transgingival site. The specific femtosecond laser processing steps and processes are:

[0046] (1) The laser spot is irradiated at the initial position of the gingival part, and the implant part is processed. The processing technology is laser frequency 10kHz, pulse energy 3000uJ, spot diameter 60μm, line spacing 50μm, and scanning speed 20mm / s to process the surface of the gingival part. During processing, the T axis rotates once, the Y axis translates 0.2mm, and the X axis moves at the same time to ensure that the laser The distance from the focal point to the sample surface remains constant, thus covering the entire surface of the transgingival site.

[0047] (2) Move the X-axis to bring the laser spot back to the initial processing position of the part, and perform secondary processing. The secondary processing process is: laser frequency 10kHz, pulse energy 200uJ, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com