Insulation treatment method of iron-nickel-molybdenum alloy soft magnetic material

A soft magnetic material, insulation treatment technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high eddy current loss, large particle size of powder, etc. The effect of small diameter and less satellite particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

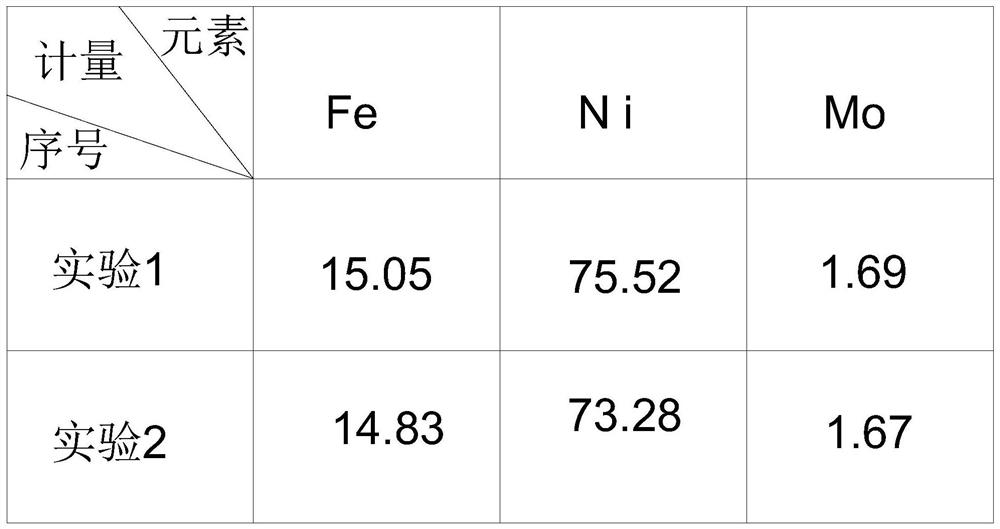

[0030] Such as figure 1 and figure 2 As shown, an insulation treatment method of an iron-nickel-molybdenum alloy soft magnetic material,

[0031] S1: Mix iron, nickel and molybdenum evenly according to the mass percentage of 17:82:2;

[0032] S2: After mixing evenly, put it into the atomization furnace, set the temperature at 1500-1800°C, heat for 2-3 hours, and prepare it by high-pressure air-water combined atomization method under the pressure of 1-6Mpa, and make it with high magnetic permeability Iron-nickel-molybdenum alloy soft magnetic powder; the specific temperature is controlled at 1700°C;

[0033] S3: The iron-nickel-molybdenum alloy soft magnetic powder is screened to select material A, A is a magnetic powder with a particle size of 10-22 μm; the magnetic powder with a particle size of 20 μm has the best uniform insulation coating effect;

[0034] S4: Put the screened material A and tetraethyl orthosilicate into a mortar and mix for 10-30 minutes; obtain materia...

Embodiment 2

[0038] This embodiment is carried out on the basis of the above-mentioned embodiments, and the ammonia solution with a mass fraction of 2 to 3% is prepared, and then 0.05 mol of cobalt chloride is added for every 250 to 300 ml of the ammonia solution, and then every 0.01 mol of cobalt chloride is added to the aforementioned solution. Add 100g of iron-nickel-molybdenum alloy soft magnetic powder to mol of cobalt chloride, stir evenly, put the above materials into a hydrothermal reaction kettle, keep warm at 170-190°C for 1-2 hours, then cool naturally to room temperature, filter with suction and wash twice with alcohol After the above, put it into an oven for drying at 50-70°C to obtain the coated magnetic powder; it is the process of cleaning and purifying the soft magnetic powder of iron-nickel-molybdenum alloy to strengthen the structural compactness of the subsequent magnetic core, and through hydrolysis Precipitation insulation coating method to improve the insulation effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com