Green and environment-friendly magnesia spinel gunning mix for converter as well as preparation and application of green and environment-friendly magnesia spinel gunning mix

A magnesia spinel, green and environmentally friendly technology, applied in the field of refractory materials for converters, can solve pollution, resource waste and environmental problems, and achieve the effects of reducing costs, reducing steelmaking costs, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1

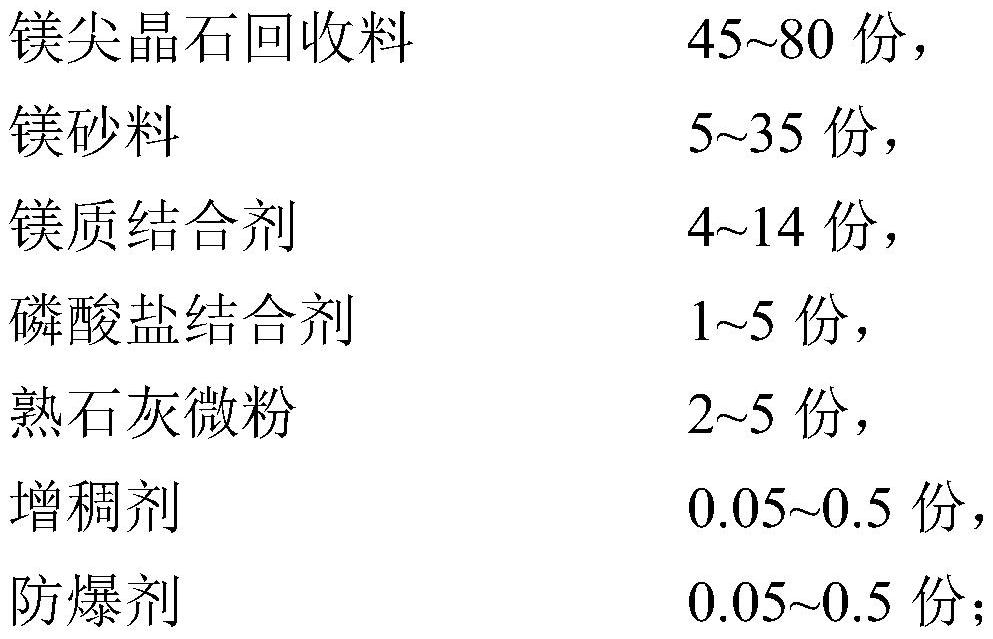

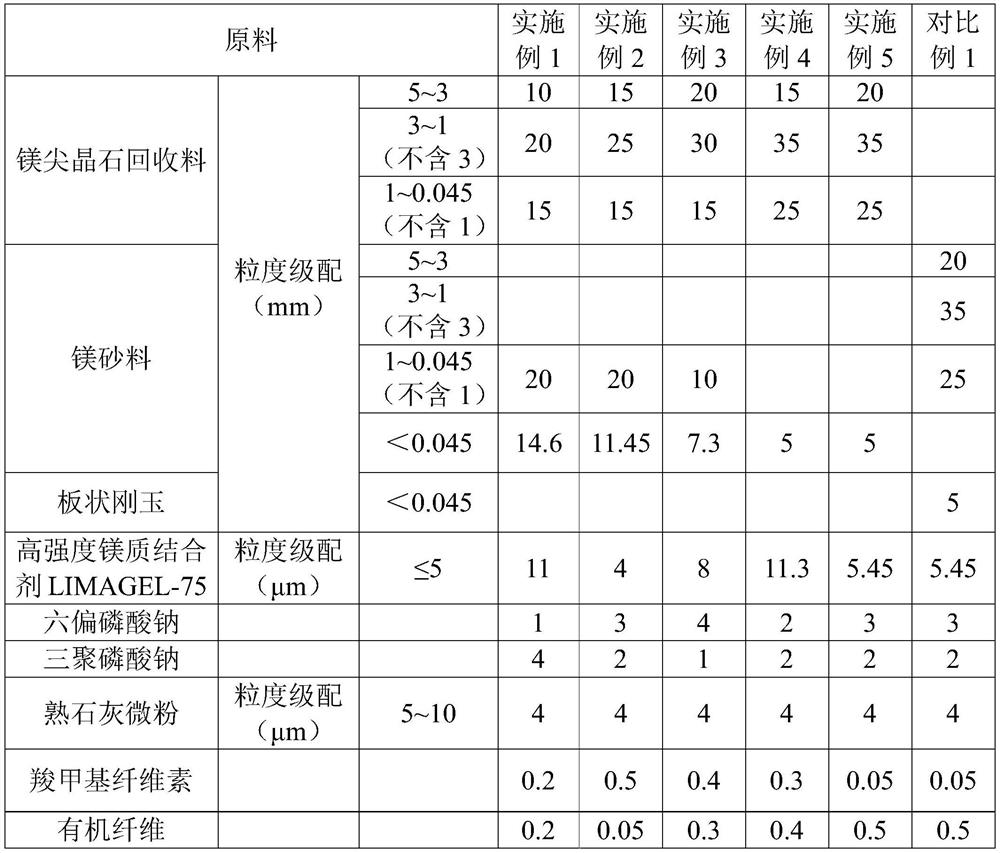

[0042] In terms of parts by mass, the raw material composition of the magnesia spinel gunning material of Examples 1 to 5 and the platy corundum gunning material of Comparative Example 1 is shown in Table 1, and the magnesia spinel reclaimed material (MgO and Al 2 o 3 The total content is not less than 95wt%), magnesia material (MgO content ≥ 95wt%), or magnesia material (MgO content ≥ 95wt%), and tabular corundum are added to the mixer in proportion to pre-mix for 1-2min, and then added in proportion Anti-explosion agent, magnesium binder (Yixing Zili Micro Powder Material Technology Co., Ltd., LIMAGEL-75 high-strength magnesium binder, particle size not greater than 5μm, MgO content in its composition ≥ 77.00wt%, SiO 2 Content ≥ 13.00wt%, loss on ignition at 950°C ≤ 6.0wt%), phosphate binder, slaked lime powder, thickener, and stir in a mixer for 3-5min to obtain the corresponding magnesium spinel Gunning material or tabular alumina gunning material. Test the amount of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com