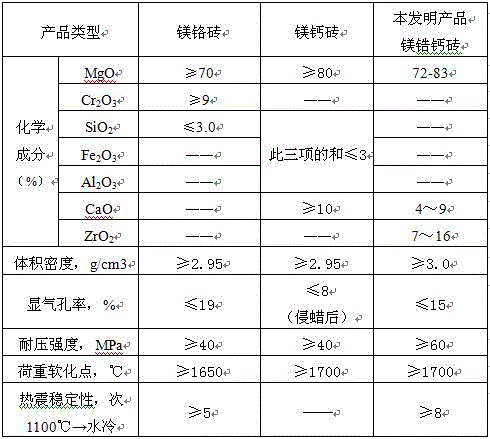

Magnesium-zirconium-calcium bricks for stainless steel smelting kilns

A technology of magnesia-zirconium-calcium brick and stainless steel, applied in the field of refractory materials, can solve problems such as pulverization of kiln lining, unsuitable for gunning and maintenance, and public hazards, and achieve good hydration resistance and suitable for gunning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Choose MgO-96 grade for fused magnesia, choose ZrO for desiliconized zirconium 2 -90 grade, lime paste requires crystallization water of slaked lime, and the content of free water contained in it is 25~40%.

[0028] The preparation method of magnesium-zirconium-calcium brick for stainless steel smelting kiln of the present invention is:

[0029] The first step, raw material weighing

[0030] 1) Weigh fused magnesia granules and powder according to the following particle size distribution

[0031] 30 parts of granular materials with a particle size of 5~3mm, 15 parts of granular materials with a particle size of 1mm

[0032] 2) Weigh 8 parts of desiliconized zirconium powder with particle size <0.088mm; 10 parts of lime paste with CaO≥95%; 0.2 parts of industrial dextrin;

[0033] The second step, material mixing

...

Embodiment 2

[0041] Fused magnesia chooses MgO-97 grade, desiliconized zirconium chooses ZrO 2 -98 grade, lime paste requires crystallization water of slaked lime, and the content of free water contained in it is 25~40%.

[0042] The preparation method of magnesium-zirconium-calcium brick for stainless steel smelting kiln of the present invention is:

[0043] The first step, raw material weighing

[0044] 1) Weigh fused magnesia granules and powder according to the following particle size distribution

[0045] 30 parts of granular materials with a particle size of 5~3mm, 15 parts of granular materials with a particle size of 1mm<3mm, 20 parts of granular materials with a particle size of 0.088mm<1mm, and 20 parts of powder materials with a particle size of ≤0.088mm;

[0046] 2) Weigh 8 parts of desiliconized zirconium powder with particle size <0.088mm; 10 parts of lime paste with CaO≥95%; 0.4 parts of industrial dextrin;

[0047] The second step, material mixing

[0048] Add the three...

Embodiment 3

[0055] Fused magnesia chooses MgO-97 grade, desiliconized zirconium chooses ZrO 2 -95 grade, lime paste requires crystallization water of slaked lime, and the content of free water contained in it is 25~40%.

[0056] The preparation method of magnesium-zirconium-calcium brick for stainless steel smelting kiln of the present invention is:

[0057] The first step, raw material weighing

[0058] 1) Weigh fused magnesia granules and powder according to the following particle size distribution

[0059]15 parts of granular materials with a particle size of 5~3mm, 30 parts of granular materials with a particle size of 1mm<3mm, 15 parts of granular materials with a particle size of 0.088mm<≤1mm, and 20 parts of powder materials with a particle size of ≤0.088mm;

[0060] 2) Weigh 12 parts of desiliconized zirconium powder with particle size <0.088mm; 13 parts of lime paste with CaO≥95%; 0.6 parts of industrial dextrin;

[0061] The second step, material mixing

[0062] Put the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com