Anti-ultraviolet release paper and preparation method thereof

An anti-ultraviolet, release paper technology, used in paper, papermaking, surface covering paper, etc., can solve problems such as affecting the normal use of release paper, degradation of release paper performance, and aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An anti-ultraviolet release paper, comprising base paper, the base paper surface is provided with a coating, and the coating surface is provided with a silicone oil layer, and the coating comprises the following raw materials in parts by weight: 100 parts of acrylic emulsion, 10 parts of white oil, 5 parts of ultraviolet absorber part, 20 parts of deionized water;

[0037] The coating is prepared by mixing acrylic emulsion, white oil, ultraviolet absorber and deionized water.

[0038] Described ultraviolet absorber is made by following steps:

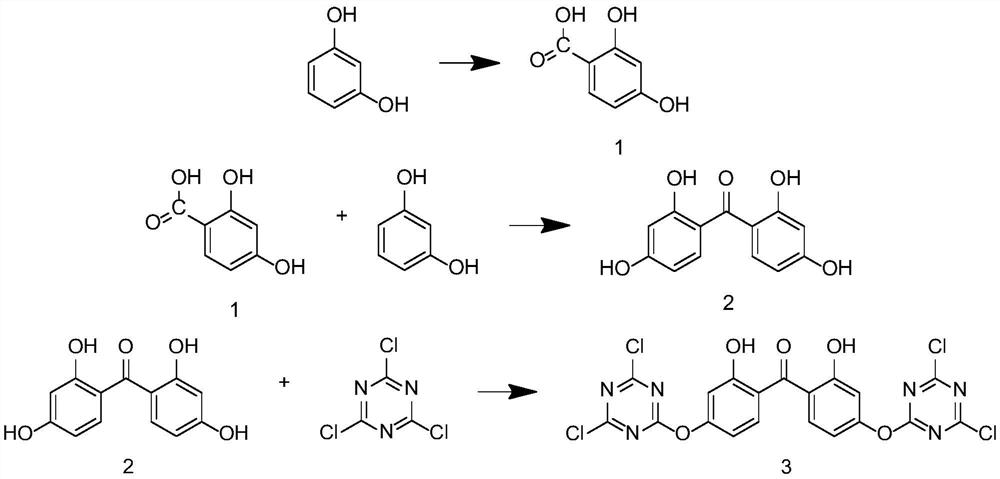

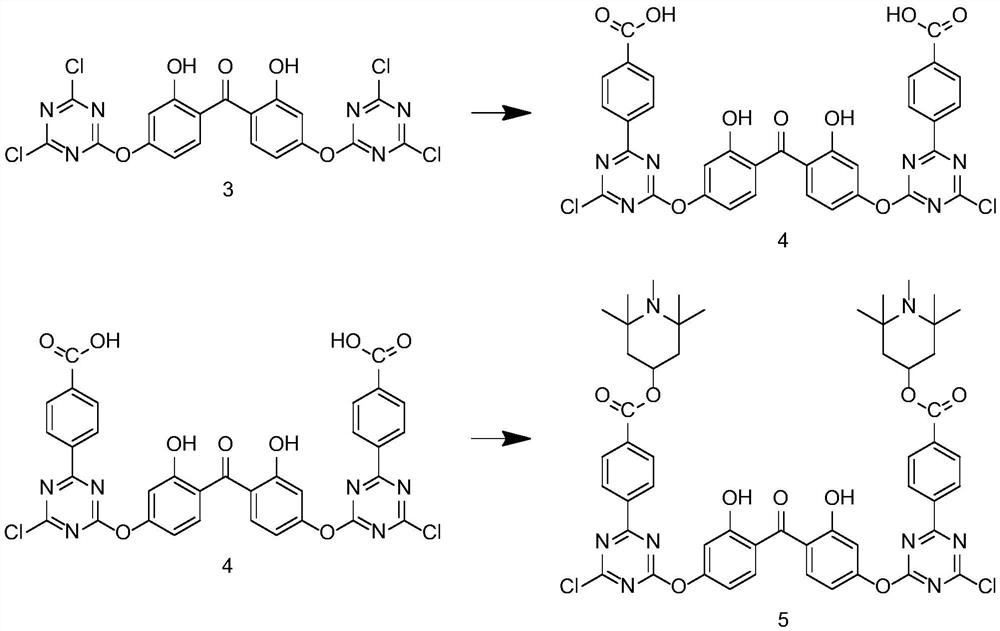

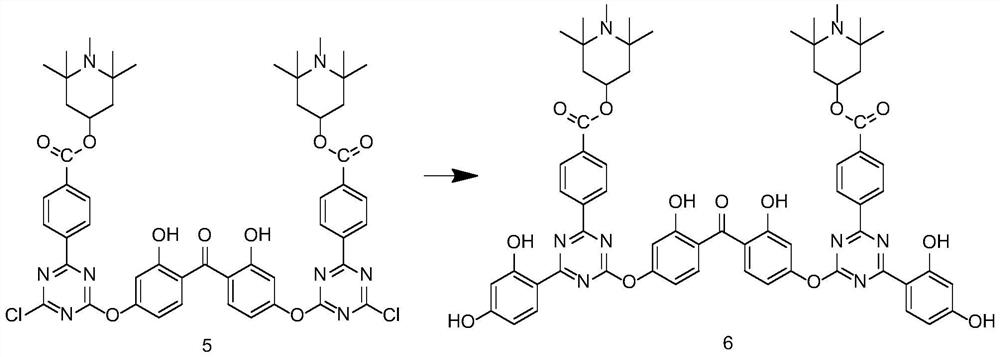

[0039]Step A1: Add cresylenol, sodium bicarbonate, and deionized water into the reaction kettle, pass in carbon dioxide, and carry out reflux reaction at a speed of 150r / min and a temperature of 100°C for 4 hours, then cool to room temperature and filter , adjust the pH value of the filtrate to 1, crystallize and wash at a temperature of 0°C to obtain intermediate 1, add resorcinol, intermediate 1, zinc chloride, phosphorus oxyc...

Embodiment 2

[0045] An anti-ultraviolet release paper, comprising base paper, the base paper surface is provided with a coating, and the coating surface is provided with a silicone oil layer, and the coating comprises the following raw materials in parts by weight: 110 parts of acrylic emulsion, 13 parts of white oil, 8 parts of ultraviolet absorber part, 25 parts of deionized water;

[0046] The coating is prepared by mixing acrylic emulsion, white oil, ultraviolet absorber and deionized water.

[0047] Described ultraviolet absorber is made by following steps:

[0048] Step A1: Add cresylenol, sodium bicarbonate, and deionized water into the reaction kettle, pass in carbon dioxide, and carry out reflux reaction at a speed of 150r / min and a temperature of 110°C for 4 hours, then cool to room temperature and filter , adjust the pH value of the filtrate to 1, crystallize and wash at a temperature of 0°C to obtain intermediate 1, add resorcinol, intermediate 1, zinc chloride, phosphorus oxy...

Embodiment 3

[0054] A kind of anti-ultraviolet release paper, comprising base paper, base paper surface is provided with coating, and coating surface is provided with silicone oil layer, and described coating comprises following raw materials in parts by weight: 120 parts of acrylic emulsion, 15 parts of white oil, 10 parts of ultraviolet absorber part, 30 parts of deionized water;

[0055] The coating is prepared by mixing acrylic emulsion, white oil, ultraviolet absorber and deionized water.

[0056] Described ultraviolet absorber is made by following steps:

[0057] Step A1: Add cresylenol, sodium bicarbonate, and deionized water into the reaction kettle, pass in carbon dioxide, and carry out reflux reaction at a speed of 200r / min and a temperature of 110°C for 6 hours, then cool to room temperature and filter , adjust the pH value of the filtrate to 1, crystallize and wash at a temperature of 0°C to obtain intermediate 1, add resorcinol, intermediate 1, zinc chloride, phosphorus oxych...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com