Silicon nitride nanorod fluorescent powder and preparation method and application thereof

A technology of nanorods and phosphors, applied in nano optics, chemical instruments and methods, nanotechnology, etc., can solve problems such as high temperatures above 2000 °C, blue luminous properties, lack of trivalent states, etc., to achieve production Low cost, good economic and social benefits, and the effect of saving process steps and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A method for preparing rare earth europium-doped silicon nitride nanorod fluorescent powder using crystalline silicon waste in the present invention comprises the following steps:

[0055] S1. Wash and dry the crystalline silicon waste and grind it into silicon powder, mix the silicon powder and the Eu source at a mass ratio of 1:(0.2-0.96) and grind it into a mixture powder of 50-400 meshes;

[0056] Preferably, the source of Eu is europium nitrate or europium acetate.

[0057] Preferably, the waste crystalline silicon is leftover material of monocrystalline silicon or polycrystalline silicon or waste materials of used crystalline silicon solar cells.

[0058] S2. Put the mixture powder ground in step S1 into a crucible, and then put the crucible into a high-temperature tube furnace;

[0059] S3, passing an inert gas into the high-temperature tube furnace, and performing sintering treatment at normal temperature and pressure;

[0060] Preferably, the inert gas is hig...

Embodiment 1

[0068] Clean and dry the leftovers of monocrystalline silicon, grind them into 50-mesh powder, mix the ground silicon powder and europium nitrate at a mass ratio of 1:0.48; then put them into a ceramic boat and place them in a high-temperature tube furnace. Feed high-purity nitrogen into the high-temperature tube furnace and turn on the high-temperature tube furnace. The flow rate of nitrogen is 30 sccm. The heating curve of the sample is first to 1000°C at a rate of 10°C / min, then to 1300°C at a rate of 4°C / min, and finally to 1440°C at a rate of 2°C / min. Insulate at this temperature for 3 hours, cool to room temperature after the reaction is over, and take out the sample to obtain silicon nitride yellow phosphor Si 3 N 4 : Eu.

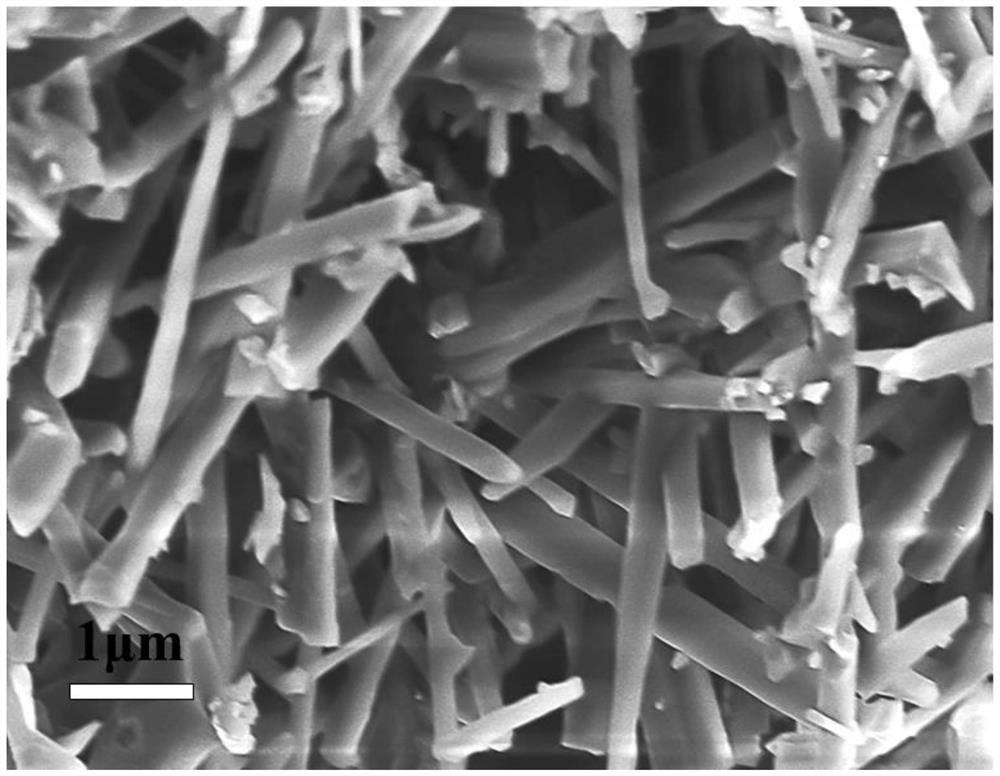

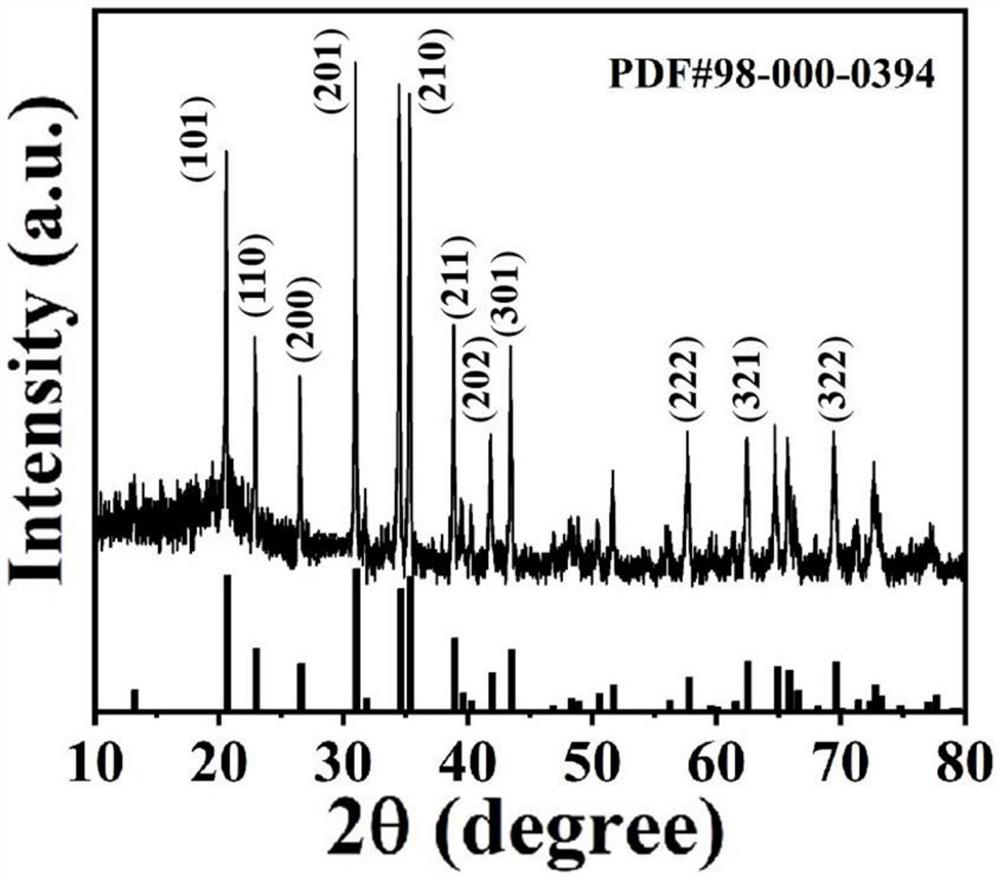

[0069] figure 1 Given the obtained Si 3 N 4 : Scanning electron micrograph (SEM) of the Eu phosphor nanomaterial, it can be seen from the figure that the morphology of the nanomaterial is rod-shaped, and the diameter of the rod-shaped structure ...

Embodiment 2

[0071] Wash and dry the scraps of monocrystalline silicon, and grind them into 100-mesh powder. The ground silicon powder is mixed with europium nitrate at a mass ratio of 1:0.6; then put into a ceramic boat and placed in a high-temperature tube furnace. Feed high-purity nitrogen into the high-temperature tube furnace and turn on the high-temperature tube furnace. The flow rate of nitrogen is 100 sccm. The heating curve of the sample is first to 1000°C at a rate of 10°C / min, then to 1300°C at a rate of 4°C / min, and finally to 1500°C at a rate of 2°C / min. Insulate at this temperature for 2 hours, cool to room temperature after the reaction is over, and take out the sample to obtain silicon nitride yellow phosphor Si 3 N 4 : Eu.

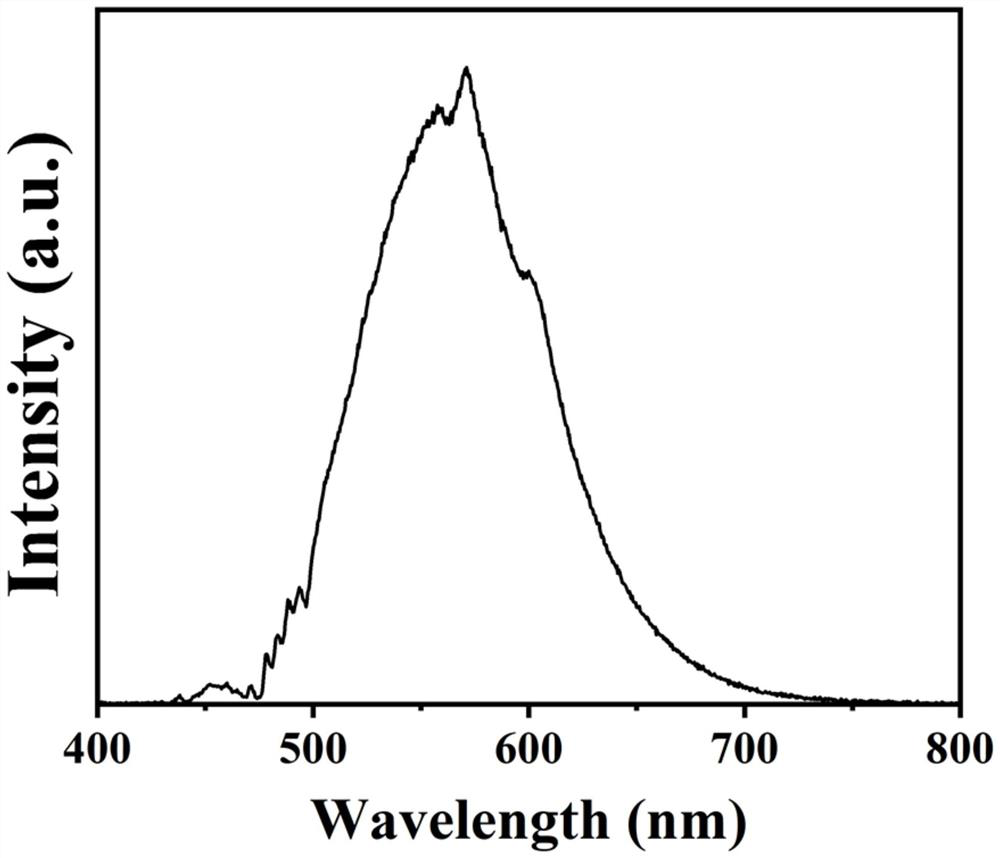

[0072] figure 2 It is the emission spectrum diagram of the material under the excitation of 365nm ultraviolet light. The central position of the luminescence is 572 nanometers, and the half-minute width is about 95 nanometers. It is a phosphor wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com