Cobalt-molybdenum sulfide composite flame retardant, fireproof coating and preparation methods of cobalt-molybdenum sulfide composite flame retardant and fireproof coating

A composite flame retardant and fire-resistant coating technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve problems such as single structure and poor charring effect, and achieve increased stability, stable structure, and rich cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

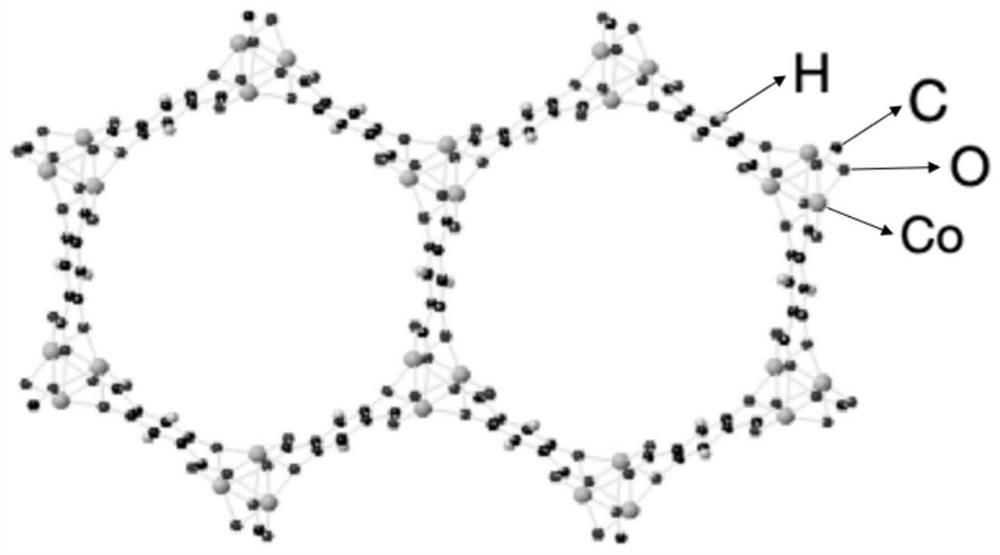

Method used

Image

Examples

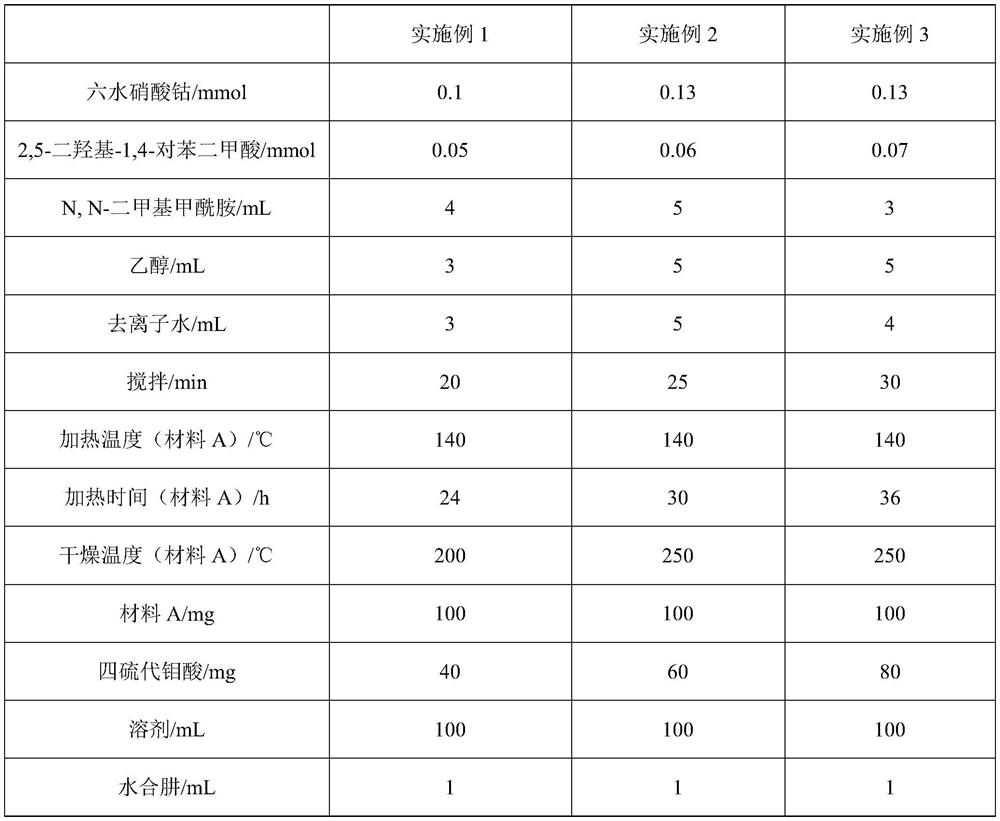

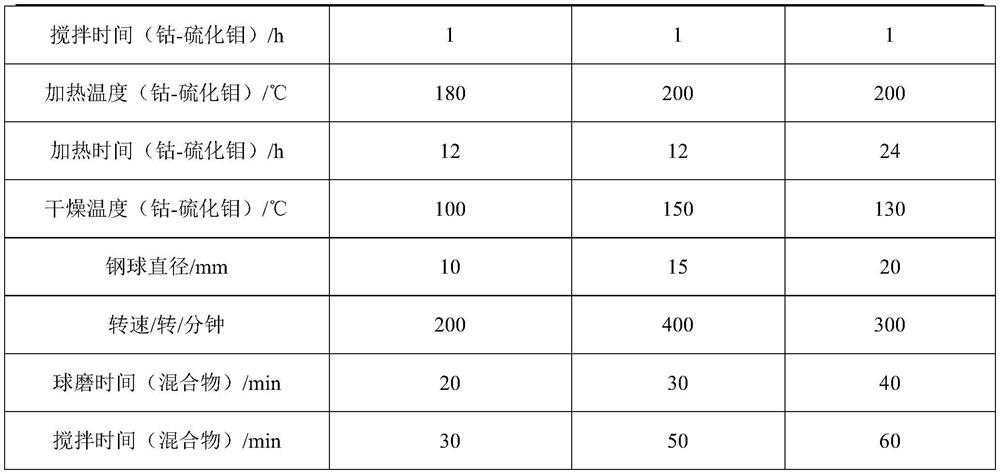

Embodiment 1

[0053] A fireproof coating based on a cobalt-molybdenum sulfide composite flame retardant, comprising the following components in parts by mass: 80 parts of epoxy resin, 2 parts of cobalt-molybdenum sulfide composite flame retardant, 10 parts of other flame retardant A, other 10 parts of flame retardant B, 2 parts of glass fiber, 10 parts of dispersant, 2 parts of titanium dioxide.

[0054] The other flame retardant A includes ammonium polyphosphate, melamine, and melamine pyrophosphate, wherein, 2 parts of ammonium polyphosphate, 2 parts of melamine, and 6 parts of melamine pyrophosphate.

[0055] The other flame retardant B includes quaternary dipentaerythritol hexahydroxystearate.

[0056] The preparation method of described cobalt-molybdenum sulfide composite flame retardant comprises the following steps:

[0057] a. Add 0.1mmol of cobalt nitrate hexahydrate and 0.05mmol of 2,5-dihydroxy-1,4-terephthalic acid to a solution containing 4mL of N,N-dimethylformamide, 3mL of e...

Embodiment 2

[0067] A fireproof coating based on cobalt-molybdenum sulfide composite flame retardant, comprising the following components in parts by mass: 90 parts of epoxy resin, 6 parts of cobalt-molybdenum sulfide composite flame retardant, 8 parts of other flame retardant A, other 15 parts of flame retardant B, 6 parts of glass fiber, 10 parts of dispersant, 5 parts of titanium dioxide.

[0068] The other flame retardant A includes melamine cyanurate.

[0069] The other flame retardant B includes pentaerythritol and poly-dipentaerythritol hexaacrylate, wherein 4 parts of pentaerythritol and 4 parts of poly-dipentaerythritol hexaacrylate.

[0070] The preparation method of described cobalt-molybdenum sulfide composite flame retardant comprises the following steps:

[0071] a. Add 0.13mmol of cobalt nitrate hexahydrate and 0.06mmol of 2,5-dihydroxy-1,4-terephthalic acid to a solution containing 5mL of N,N-dimethylformamide, 5mL of ethanol and 5mL of deionized water in the mixed solven...

Embodiment 3

[0081] A fireproof coating based on a cobalt-molybdenum sulfide composite flame retardant, comprising the following components in parts by mass: 120 parts of epoxy resin, 8 parts of cobalt-molybdenum sulfide composite flame retardant, 13 parts of other flame retardants A, other flame retardants Fuel B 14 parts, glass fiber 5 parts, dispersant 14 parts, titanium dioxide 8 parts.

[0082] The other flame retardants A include ammonium polyphosphate, melamine, melamine pyrophosphate and melamine polyphosphate, wherein 5 parts of ammonium phosphate, 5 parts of melamine, 1 part of melamine pyrophosphate and 2 parts of melamine polyphosphate.

[0083] The other flame retardant B includes pentaerythritol, poly-dipentaerythritol hexaacrylate and poly-dipentaerythritol pentaacrylate, wherein, 4 parts of pentaerythritol, 4 parts of poly-dipentaerythritol hexaacrylate, and 6 parts of poly-dipentaerythritol pentaacrylate.

[0084] The preparation method of described cobalt-molybdenum sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com