Multi-functional aluminum-plastic cloth composite film with layered structure and preparation method thereof

A layered structure, multi-functional technology, applied in the direction of metal layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as mildew, achieve fast compounding speed, excellent moisture resistance effect, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0036] A multifunctional laminated aluminum-plastic cloth composite film, including a substrate layer, a barrier layer and a heat-sealing layer;

[0037] The substrate layer includes a cloth base layer 300, and the material used for the cloth base layer 300 is one of polyester non-woven fabric, nylon non-woven fabric, multi-functional Oxford cloth or woven cloth. The cloth base layer 300 serves as a base material layer and plays a role of supporting the effect of the basic multifunctional layered structure.

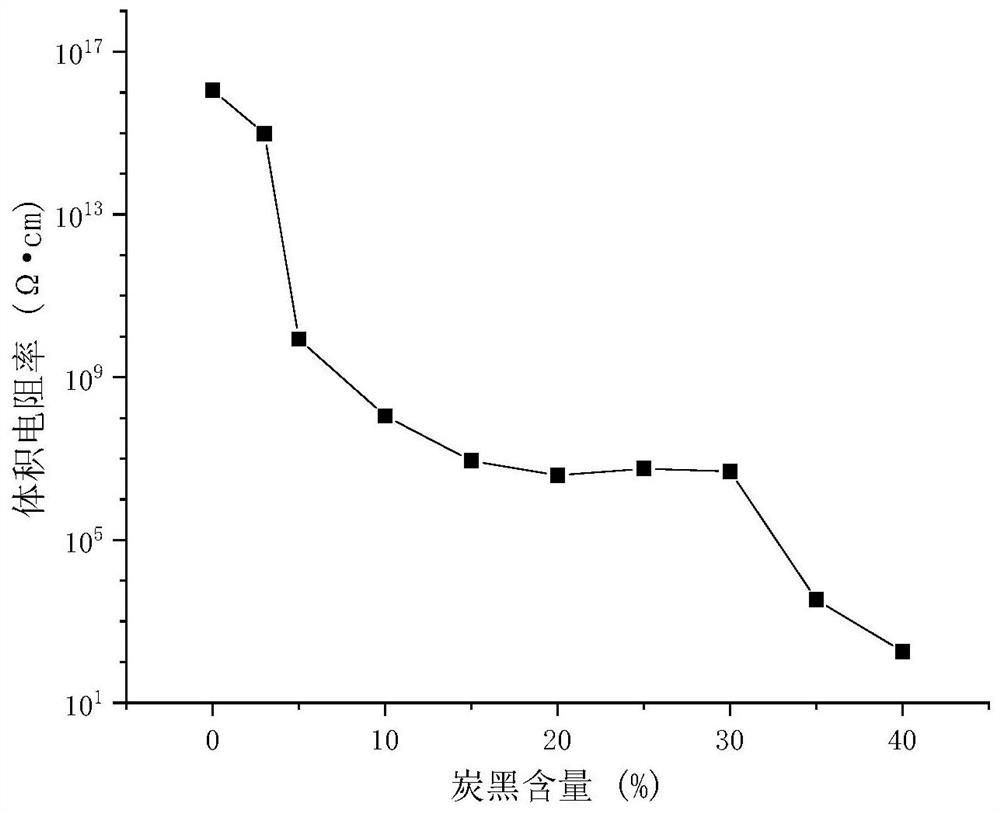

[0038] The heat seal layer includes an antistatic polyethylene layer 500 . The antistatic polyethylene layer 500 is a heat-sealing layer. The heat-sealing layer made of anti-static polyethylene material can prevent static interference.

[0039] The barrier layer comprises an aluminum foil layer 100 , an outer thermoplastic polymer film layer 200 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com