Metal SLM printing system based on Gaussian light beam and light beam shaping composite beam

A Gaussian beam and printing system technology, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve problems such as limiting the performance of anti-Gaussian optical products, splashing, etc., to improve energy utilization, increase filling speed, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

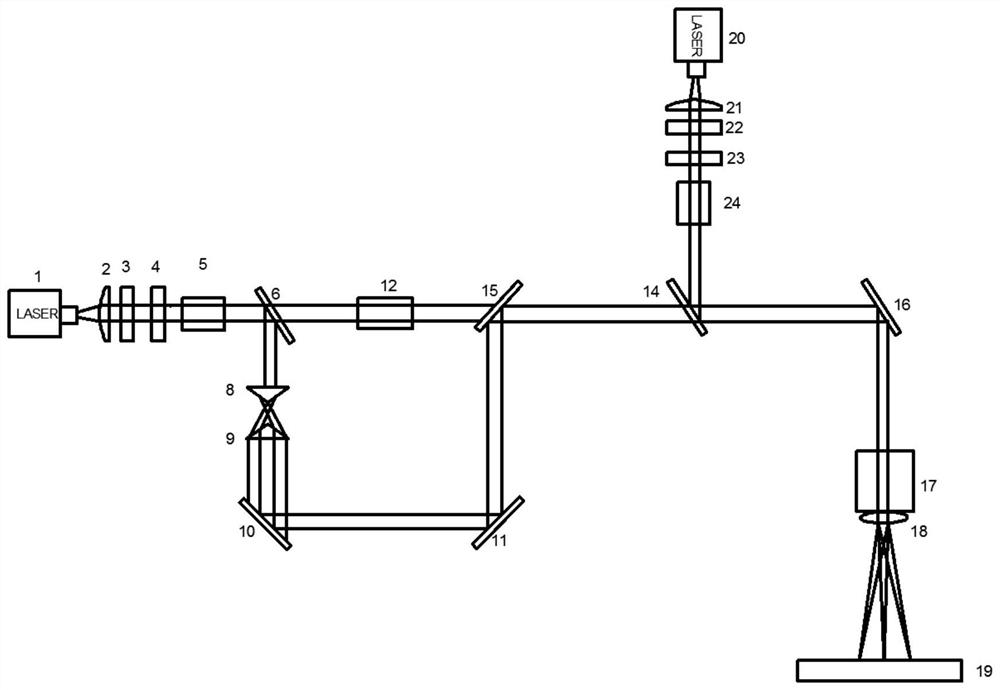

[0046] Such as figure 1 , 6 , 7, 8, and 9, the composite beam metal SLM printing system based on dual light source beam shaping provided by this specific embodiment includes a Gaussian beam metal SLM printing system, a ring beam shaping system, a beam shaper 12, and a beam coupler 14 , the second Gaussian light emitting unit and four linear modules, preferably, the linear module can choose a model PKH40 ball screw linear module from Chengdu Panyan Machinery Co., Ltd.

[0047] The Gaussian beam metal SLM printing system includes a first Gaussian light emitting unit, a printing unit and a working platform 19. The first Gaussian light emitting unit includes a first laser and first lasers arranged in sequence along the propagation direction of the Gaussian beam emitted by the first laser 1. A collimator 2 , a first half-wave plate 3 , a first polarizer 4 and a first variable magnification beam expander 5 , and the printing unit includes a fifth total reflection mirror 16 , a vibr...

Embodiment 2

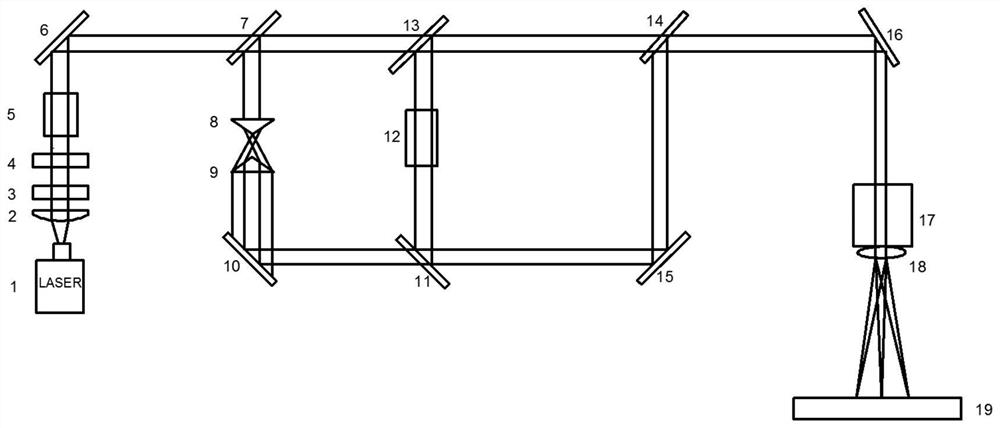

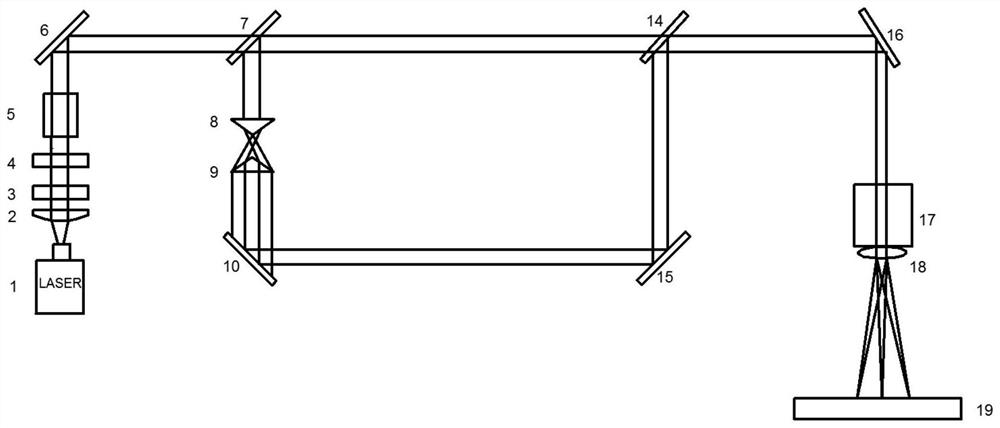

[0078] Such as Figure 2 to Figure 9 As shown, the composite beam metal SLM printing system based on the Gaussian beam of a single light source provided in Embodiment 2 includes a Gaussian beam metal SLM printing system, a first total reflection mirror 6, a first beam splitter mirror 7, and a second beam splitter mirror 13 , ring beam shaping system, beam coupler 14, beam shaper 12, third total reflection mirror 11 and four linear modules.

[0079] The Gaussian beam metal SLM printing system includes a first Gaussian light emitting unit, a printing unit and a working platform. The first Gaussian light emitting unit includes a first laser 1 and first quasi-lights arranged in sequence along the propagation direction of the Gaussian beam emitted by the first laser 1. Straightener 2, first half-wave plate 3, first polarizer 4 and first variable magnification beam expander 5, the printing unit includes fifth total reflection mirror 16, galvanometer system 17 and field lens 18.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com