Mask capable of resisting bacteria and killing viruses based on dim light catalysis and derivative coating material

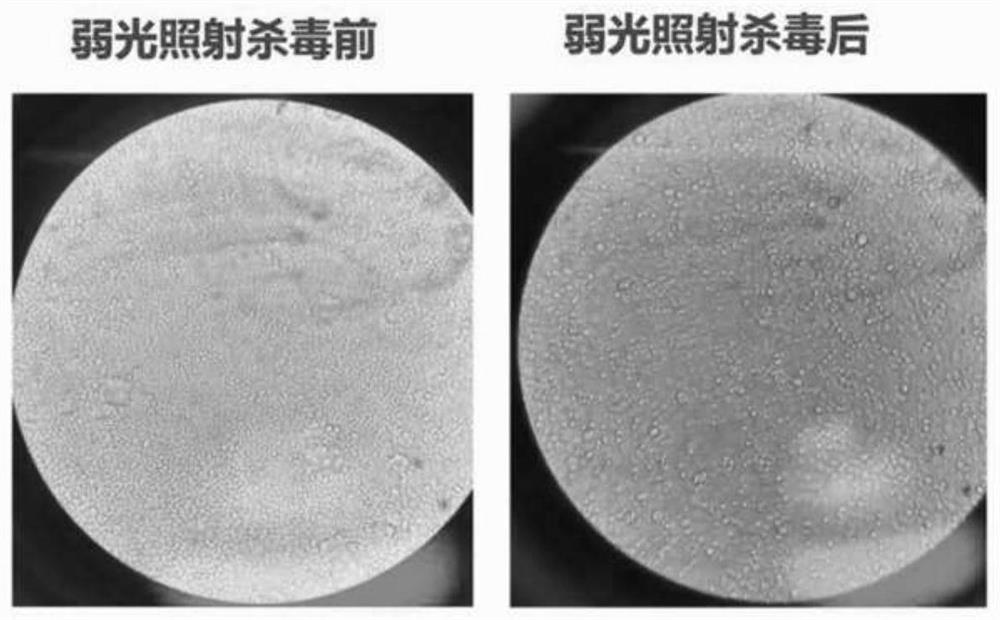

A coating material and weak light technology, applied in the field of environmental functional materials and health care, can solve the problems of waste of resources, limited ability to intercept viruses with small particle size, blockage of porous physical structure, etc., to achieve resource saving, excellent antivirus and antibacterial effect, effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0035] A kind of derived coating material for masks, namely surface-loaded polypropylene melt-blown cloth and its preparation:

[0036] (1) A certain amount of metal hydroxide (mixture, 1g, commercially available in analytical grade) and distilled water (350ml) are prepared into an ultra-dilute mixed solution according to a certain mass ratio.

[0037] (2) Then immerse the polypropylene non-woven fabric layer in the above mixture for 3 minutes, take it out and let it air-dry naturally, repeat this 5 times.

[0038](3) The polypropylene melt-blown non-woven fabric layer 1 that cured the photocatalyst in this embodiment was sprayed with medical hydrogen peroxide at a concentration of 2%, and the amount of spraying ranged from 1.5 to 2 ml.

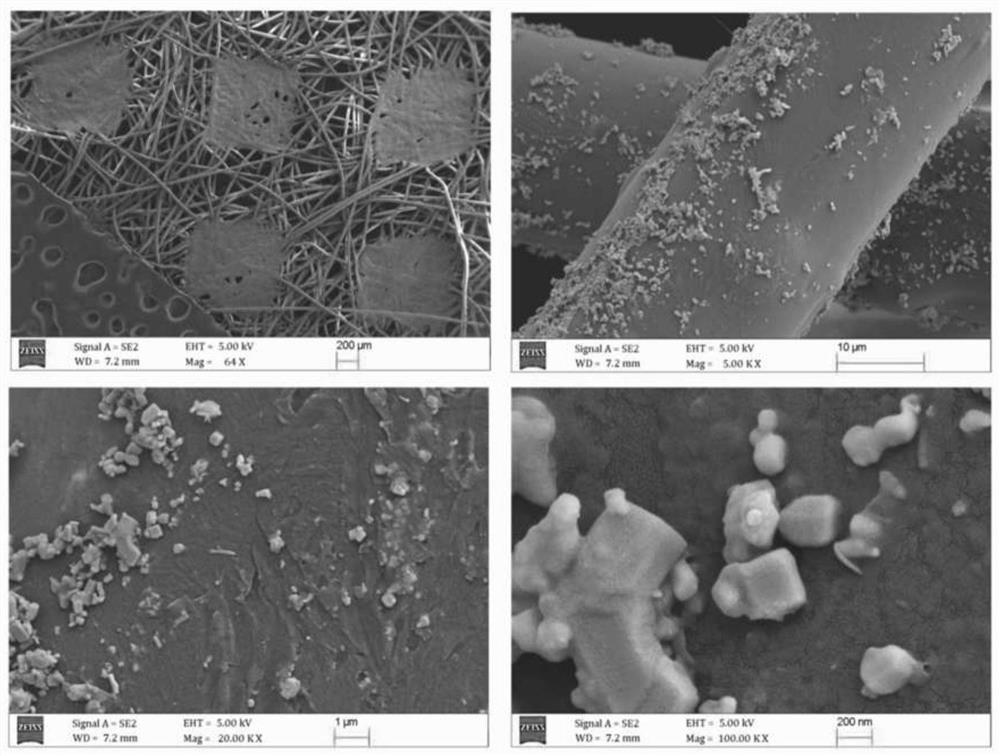

[0039] The scanning electron microscope image of polypropylene melt-blown cloth layer loaded with weak light photocatalyst is as follows figure 2 shown.

preparation example 2

[0041] The surface-loaded photocatalyst polypropylene melt-blown cloth obtained in Preparation 1 is used to prepare masks, and the masks are sewn in the following order from outside to inside: polypropylene melt-blown non-woven fabric layer 1, cotton absorbent sheet 2, filter cloth layer 3. Cotton absorbent sheet 4. Non-woven fabric layer 5. Get mask 1.

preparation example 3

[0043] A kind of derivative coating material used for face masks, i.e. surface polypropylene melt-blown cloth and its preparation:

[0044] (1) A certain amount of metal hydroxide (model: Yzcts mixture, 1 g, commercially available of analytical grade) and distilled water (350 ml) were prepared according to a certain mass ratio to prepare an ultra-dilute mixed solution.

[0045] (2) Then immerse the polypropylene non-woven fabric layer in the above mixture for 3 minutes, take it out and let it air-dry naturally, repeat this 5 times.

[0046] (3) The polypropylene melt-blown non-woven fabric layer 1 that cured the photocatalyst in this embodiment was sprayed with medical hydrogen peroxide at a concentration of 2%, and the amount of spraying ranged from 1.5 to 2 ml.

[0047] The scanning electron microscope image of polypropylene melt-blown cloth layer loaded with weak light photocatalyst is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com