A composite metal lithium negative electrode and its preparation method and application

A composite metal and lithium negative electrode technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the lack of stable SEI interface protection of three-dimensional current collectors, the difficulty of avoiding the influence of volume expansion in electrolyte modification, and the high cost of artificial SEI films and other problems, to achieve the effect of inhibiting the growth of lithium dendrites, avoiding irreversible attenuation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of a composite metal lithium negative electrode, which comprises the following steps:

[0040] Firstly, the three-dimensional carbon-based current collector with porous structure is pretreated with lithiophilic metal salt;

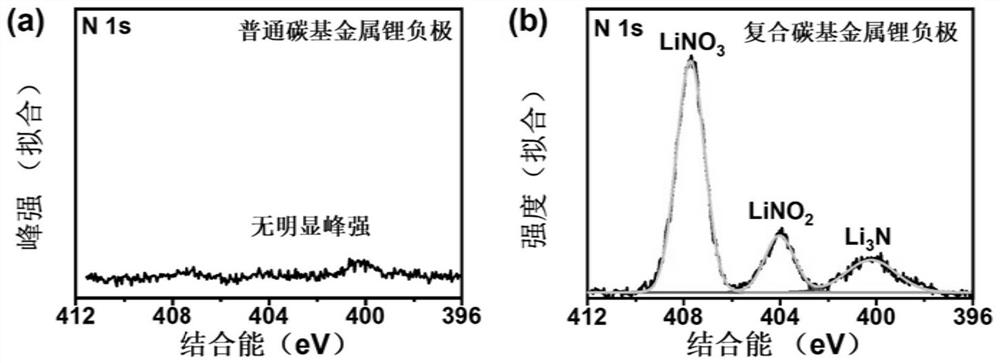

[0041] The molten metal lithium is then composited with the pretreated three-dimensional carbon-based current collector, and a lithiophilic metal and a lithium salt are generated through a substitution reaction to obtain a composite metal lithium negative electrode.

[0042] Specifically, after cleaning and drying the three-dimensional carbon-based current collector with a porous structure, an infiltration treatment is performed in a lithiophilic metal salt solution, and the three-dimensional carbon-based current collector after the infiltration treatment is dried in a vacuum or an inert atmosphere, and then melted The metal lithium is recombined with the three-dimensional carbon-based current c...

Embodiment 1

[0054] The film-like three-dimensional carbon fiber paper with a porosity of 60% and a thickness of 150 μm was repeatedly washed three times with deionized water, alcohol and acetone, and dried in a vacuum drying box to obtain a clean three-dimensional carbon-based current collector. A 0.5 mol / L silver nitrate aqueous solution was prepared with deionized water, the three-dimensional carbon-based current collector was soaked in the aqueous solution for 3 hours, the three-dimensional carbon-based current collector fully soaked in the solution was taken out, dried at room temperature for 10 hours, and then placed in a vacuum drying oven Dry at 70°C for 8h.

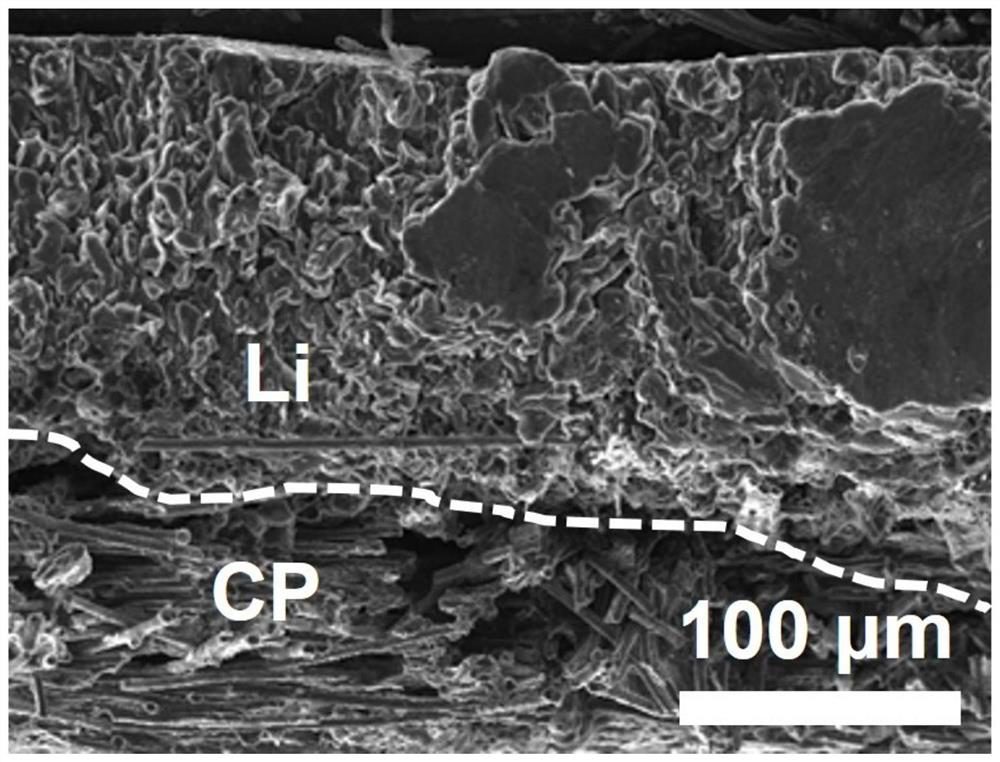

[0055] The dried three-dimensional carbon-based current collector was transferred into a glove box under a high-purity argon atmosphere, and contacted with molten lithium metal at a temperature of 200 °C. The lithiophilic metal salt in it would undergo a substitution reaction with metal lithium to obtain composite metal lithiu...

Embodiment 2

[0061] Consistent with the preparation methods of the composite metal lithium negative electrode, half-cell and full-cell in Example 1, the concentration of the silver nitrate aqueous solution was adjusted to 1 mol / L, and other conditions remained unchanged.

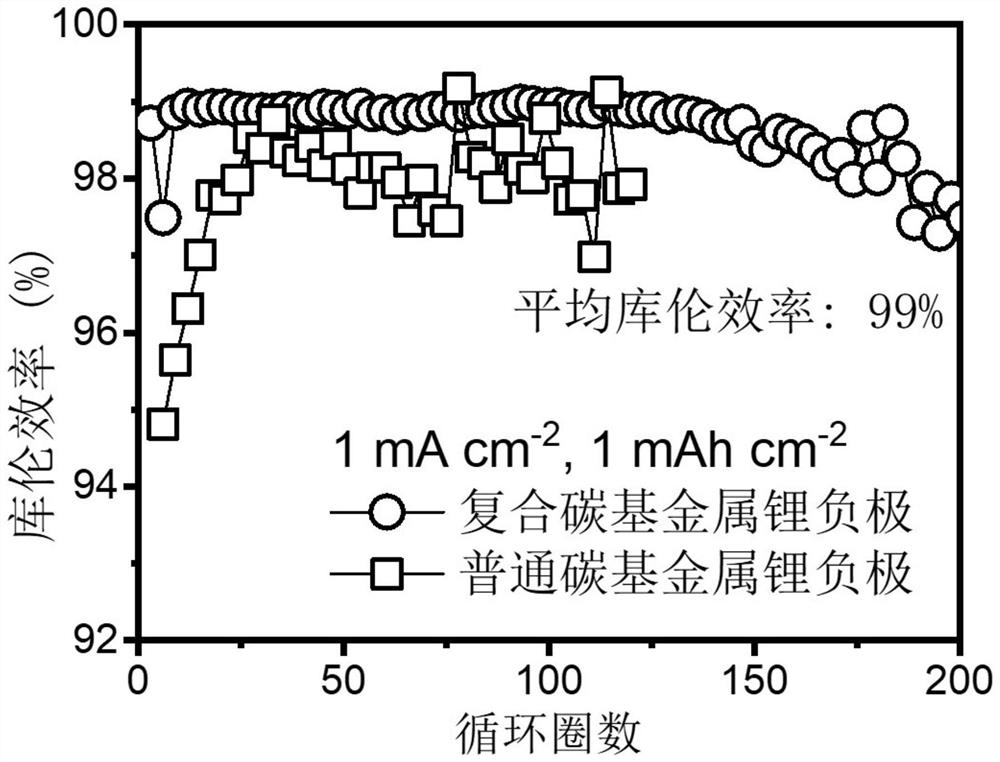

[0062] The cycle performance test is carried out on the lithium-copper half-cell prepared in this example, such as image 3 As shown, the composite metal lithium anode treated by this method has a high current (1 mA cm -2 ) can be stably cycled for 200 cycles with an average Coulombic efficiency of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com