Application of pure iron filter material in gas phase magnesium purification and its production system

A filter material and pure iron technology, applied in the field of magnesium purification production system, can solve the problems of high cost, low preparation efficiency, difficult to produce magnesium, etc., and achieve the effect of improving efficiency, simple structure, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] like Figure 4 As shown, a gas-phase magnesium purification system comprising a pure iron filter material includes a crucible device 1, a magnesium vapor channel 2, a dust removal device 3 and a vacuum device 4 connected in sequence;

[0051] The crucible device 1 is provided with an electric furnace device 5;

[0052] The crucible device 1 is provided with a hopper mechanism 11;

[0053] A filter mechanism 21 and a crystallization mechanism 22 are sequentially arranged in the magnesium vapor channel 2;

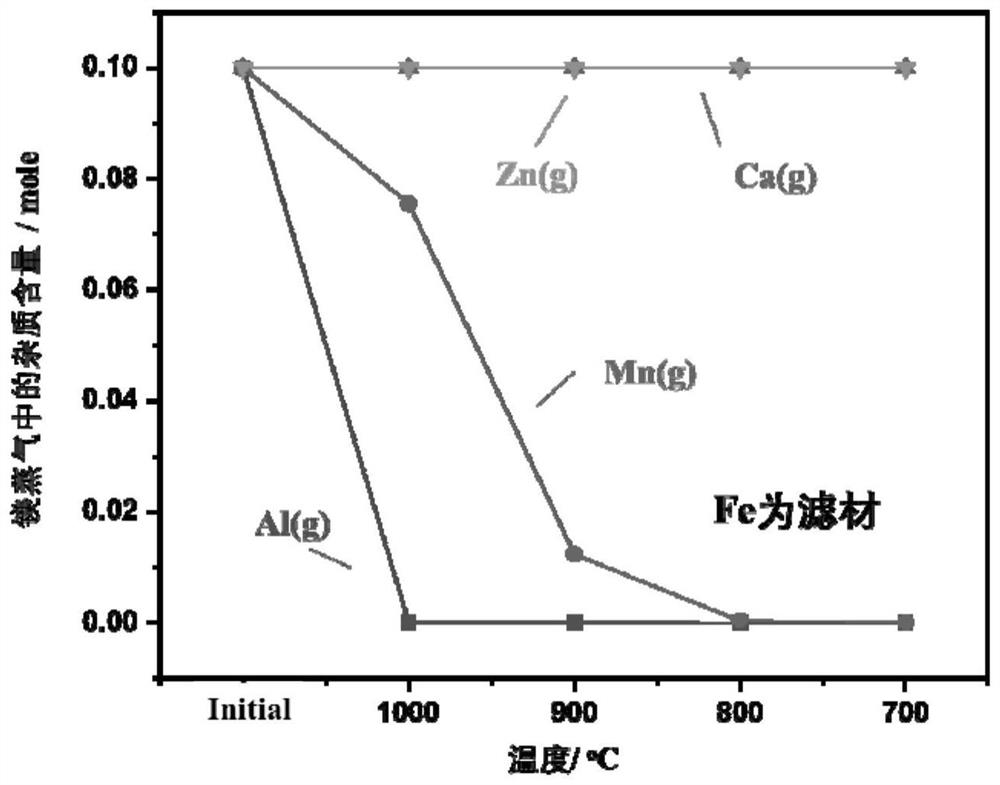

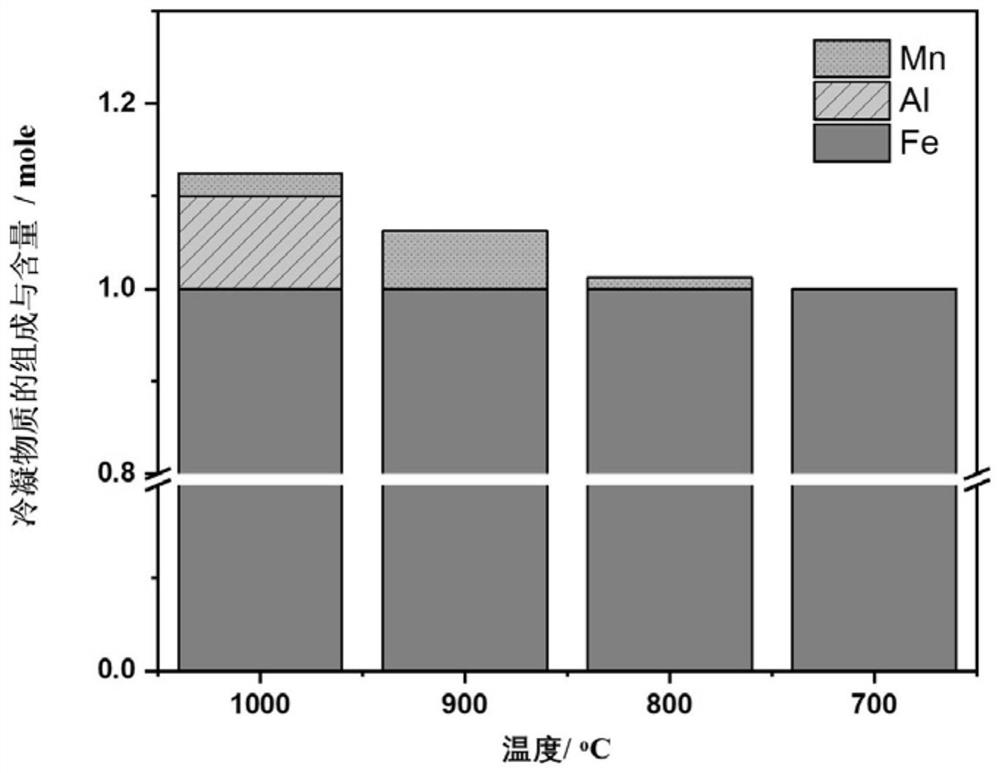

[0054] The filter mechanism 21 is provided with a pure iron filter material;

[0055] The crystallization mechanism 22 is provided with a cooling device 6;

[0056] The pure iron filter material is metal iron foam; the purity of the metal foam iron is above 99.5%, and the pore diameter of the foam metal iron is 30ppi.

Embodiment 2

[0058] A gas-phase magnesium purification system comprising a pure iron filter material, comprising a crucible device 1, a magnesium vapor channel 2, a dust removal device 3 and a vacuum device 4 connected in sequence;

[0059] The crucible device 1 is provided with an electric furnace device 5;

[0060] An insulating layer 7 is arranged between the crucible device 1 and the electric furnace device 5;

[0061] The crucible device 1 is provided with a hopper mechanism 11;

[0062] A filter mechanism 21 and a crystallization mechanism 22 are sequentially arranged in the magnesium vapor channel 2;

[0063] A heating device is arranged outside the magnesium vapor channel 2; the heating device is divided into two sections, the heating device is divided into two sections, and the filtering mechanism 21 is arranged between the first section and the second section;

[0064] The filter mechanism 21 is provided with a pure iron filter material;

[0065] The crystallization mechanism ...

Embodiment 3

[0068] A gas-phase magnesium purification system comprising a pure iron filter material, comprising a crucible device 1, a magnesium vapor channel 2, a dust removal device 3 and a vacuum device 4 connected in sequence;

[0069] The crucible device 1 is provided with an electric furnace device 5;

[0070] An insulating layer 7 is arranged between the crucible device 1 and the electric furnace device 5;

[0071] The crucible device 1 is provided with a hopper mechanism 11;

[0072] A heating device is arranged outside the magnesium vapor channel 2;

[0073] A filter mechanism 21 and a crystallization mechanism 22 are sequentially arranged in the magnesium vapor channel 2;

[0074] The filter mechanism 21 is provided with a pure iron filter material;

[0075] The crystallization mechanism 22 is provided with a cooling device 6;

[0076] The pure iron filter material is iron fiber; the purity of the iron fiber is above 99.5%, and the aperture of the iron fiber is 100-400 mesh....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com