Application of Elemental Silicon Filter Material in Gas Phase Magnesium Purification and Production System Containing It

A production system and technology of elemental silicon, applied in the direction of improving process efficiency, can solve the problems of low preparation efficiency, low yield of high-purity magnesium, and high cost, and achieve the effects of reducing nucleation energy barrier, reducing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

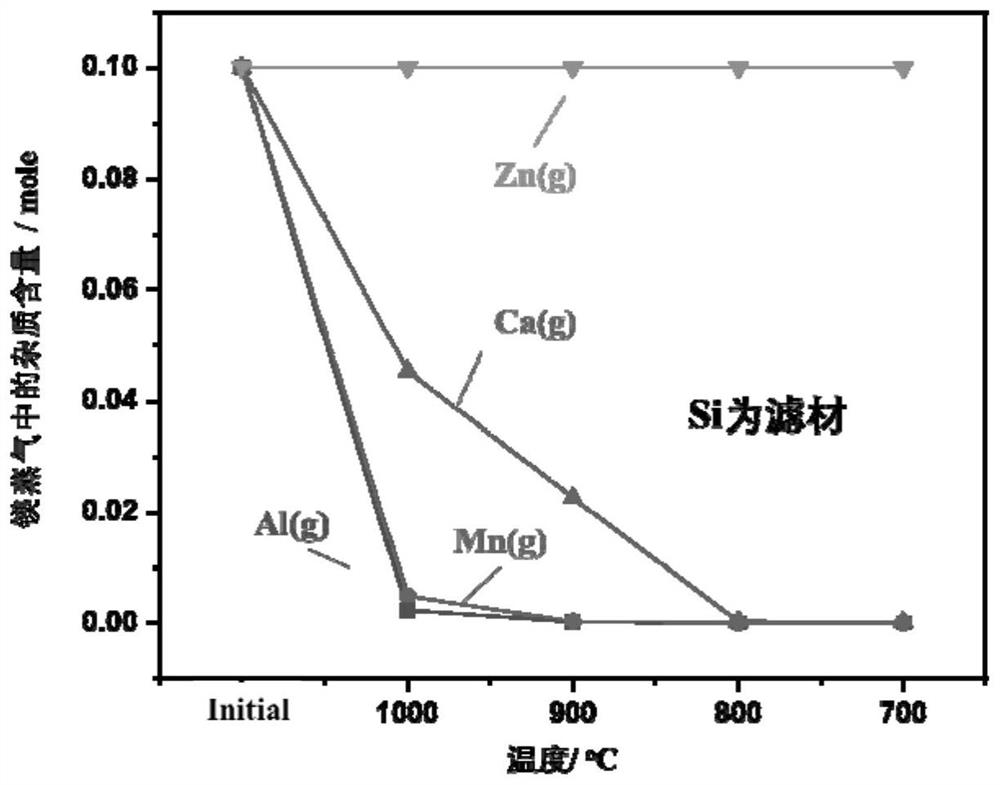

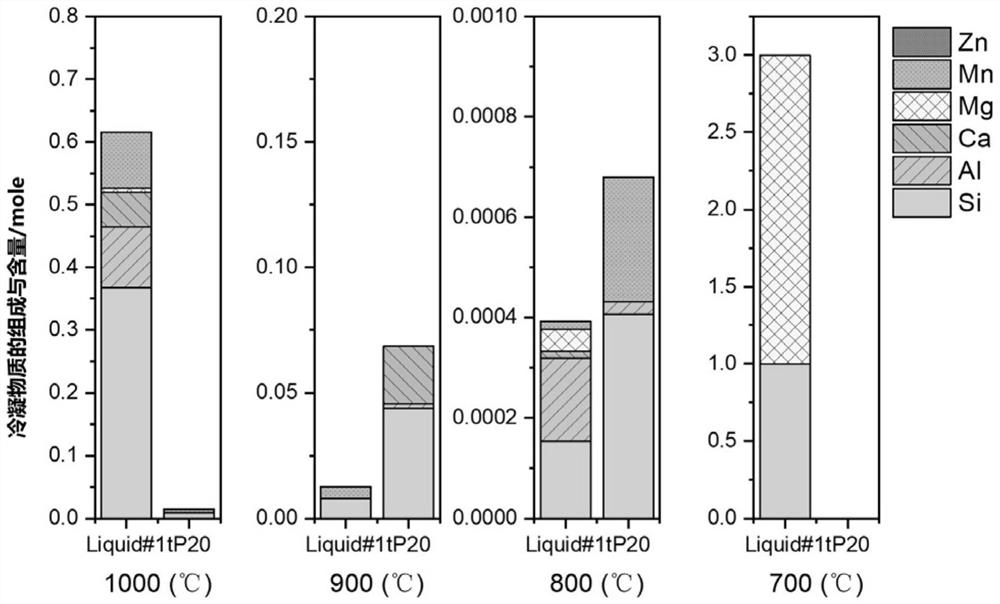

Method used

Image

Examples

Embodiment 1

[0049] Such as Figure 4 As shown, a gas-phase magnesium purification system comprising elemental silicon filter material includes a crucible device 1, a magnesium vapor channel 2, a dust removal device 3 and a vacuum device 4 connected in sequence;

[0050] The crucible device 1 is provided with an electric furnace device 5;

[0051] The crucible device 1 is provided with a hopper mechanism 11;

[0052] A filter mechanism 21 and a crystallization mechanism 22 are sequentially arranged in the magnesium vapor channel 2;

[0053] The filter mechanism 21 is provided with a simple silicon filter material;

[0054] The crystallization mechanism 22 is provided with a cooling device 6;

[0055] The elemental silicon filter material is elemental silicon particles, and the particle diameter of the elemental silicon particles is 0.1-5 mm.

Embodiment 2

[0057] A gas-phase magnesium purification system comprising an elemental silicon filter material, comprising a crucible device 1, a magnesium vapor channel 2, a dust removal device 3 and a vacuum device 4 connected in sequence;

[0058] The crucible device 1 is provided with an electric furnace device 5;

[0059] An insulating layer 7 is arranged between the crucible device 1 and the electric furnace device 5;

[0060] The crucible device 1 is provided with a hopper mechanism 11;

[0061] A heating device is arranged outside the magnesium vapor channel 2;

[0062] A filter mechanism 21 and a crystallization mechanism 22 are sequentially arranged in the magnesium vapor channel 2;

[0063] The heating device is divided into two sections, and the filter mechanism 21 is arranged between the first section and the second section;

[0064] The filter mechanism 21 is provided with a simple silicon filter material;

[0065] The crystallization mechanism 22 is provided with a coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com