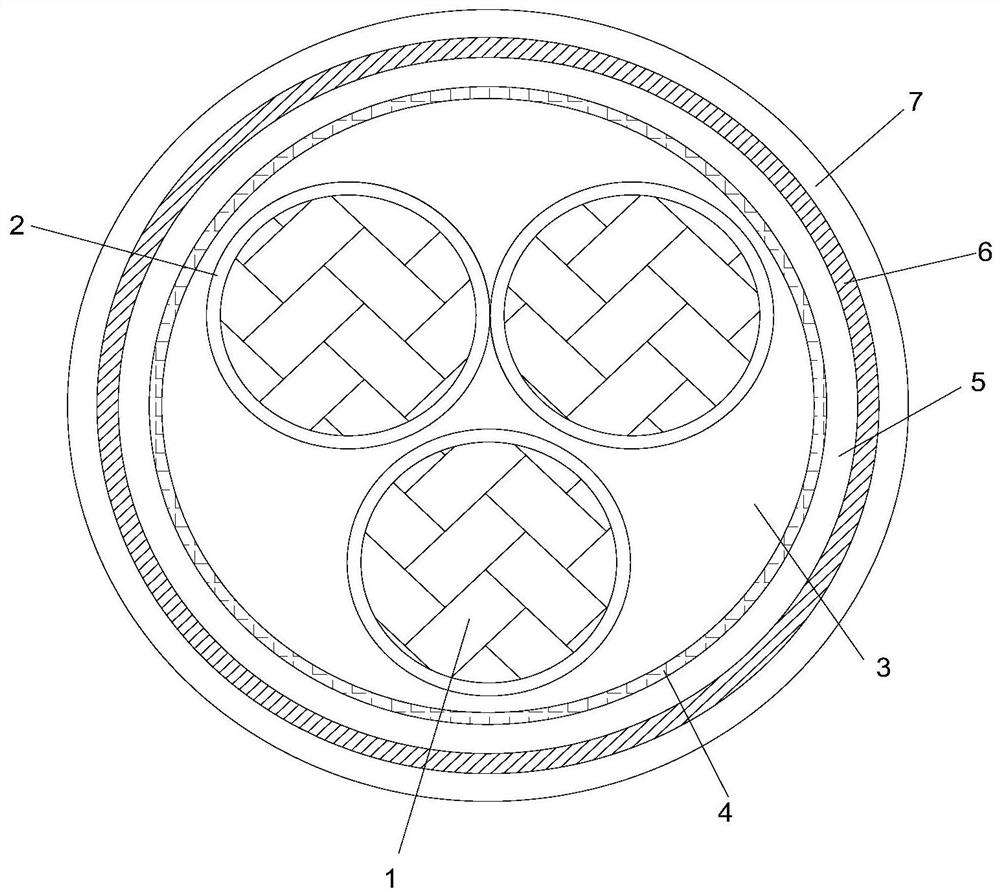

Aluminum alloy conductor cross-linked polyethylene insulation interlocking armored flame-retardant power cable

A technology of aluminum alloy conductor and cross-linked polyethylene, applied in power cables, insulated cables, conductors, etc., can solve the problems of fire, wire and cable short circuit, poor flame retardant effect of wire and cable, etc., to improve compatibility, improve Flame retardancy, improved barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

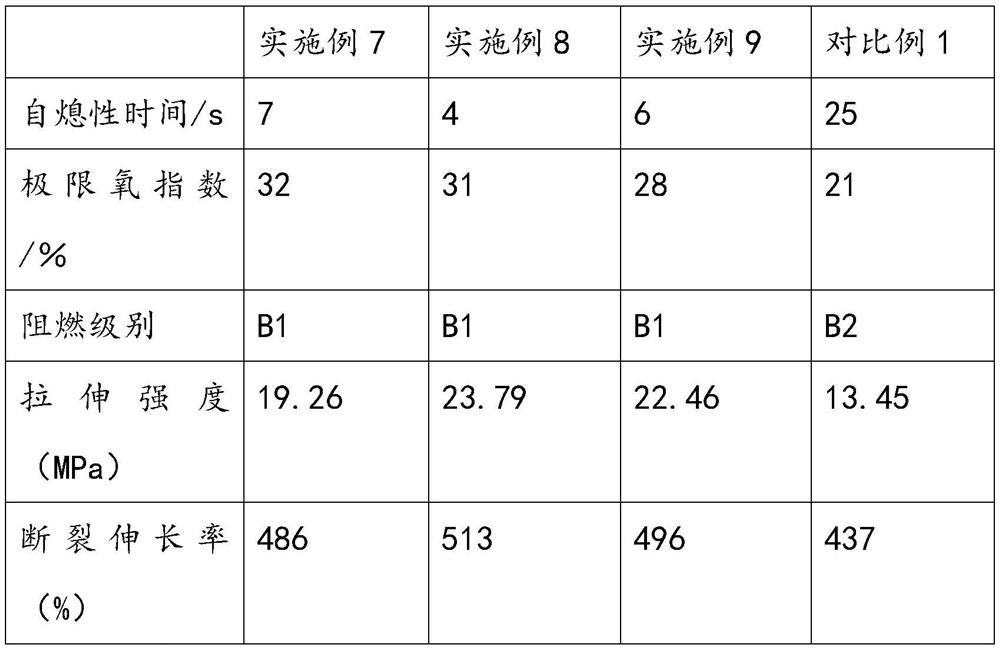

Examples

Embodiment 1

[0035] Preparation of flame retardant:

[0036] S1: Vacuumize the reaction kettle, and after nitrogen is introduced, add magnesium powder and tetrahydrofuran into the reaction kettle, adjust the temperature to minus 15°C, and then slowly add (chloromethyl)trichlorosilane and tetrahydrofuran dropwise to control the magnesium powder and tetrahydrofuran. . The dosage ratio of (chloromethyl)trichlorosilane is 1.25g: 25mL: 3.62mL. After the dropwise addition, the temperature is raised to 55°C, and the reaction is carried out for 2.5h to obtain intermediate A;

[0037] S2: Slowly add ethynylmagnesium bromide solution dropwise to intermediate A, keep the temperature at 0-5°C, raise the temperature to 65-68°C after the dropwise addition, stir and react for 14 hours, cool to minus 10°C after the reaction, and then Add lithium aluminum hydride, stir and react for 12 hours, and finally add hydrochloric acid solution dropwise. Set for 5 hours, centrifuge and wash 5 times after the reacti...

Embodiment 2

[0042] Preparation of flame retardant:

[0043] S1: Vacuumize the reaction kettle, and after nitrogen gas is introduced, add magnesium powder and tetrahydrofuran into the reaction kettle, adjust the temperature to minus 10°C, and then slowly add (chloromethyl)trichlorosilane and tetrahydrofuran dropwise to control the magnesium powder and tetrahydrofuran. . The dosage ratio of (chloromethyl)trichlorosilane is 1.25g: 25mL: 3.62mL. After the dropwise addition, the temperature is raised to 60°C, and the reaction is carried out for 2.7h to obtain intermediate A;

[0044] S2: Slowly add ethynylmagnesium bromide solution dropwise to intermediate A, keep the temperature at 3°C, raise the temperature to 66.5°C after the dropwise addition, stir and react for 16 hours, cool to minus 7°C after the reaction, and then add aluminum tetrahydrogen Lithium, stirred and reacted for 13 hours, and finally added hydrochloric acid solution dropwise, controlling the dosage ratio of intermediate A, e...

Embodiment 3

[0049] Preparation of flame retardant:

[0050] S1: Vacuumize the reaction kettle, and after feeding nitrogen, add magnesium powder and tetrahydrofuran into the reaction kettle, adjust the temperature to minus 5°C, and then slowly add (chloromethyl)trichlorosilane and tetrahydrofuran dropwise to control the magnesium powder and tetrahydrofuran. . The dosage ratio of (chloromethyl)trichlorosilane is 1.25g: 25mL: 3.62mL. After the dropwise addition, the temperature is raised to 65°C, and the reaction is carried out for 3 hours to obtain intermediate A;

[0051] S2: Slowly add ethynylmagnesium bromide solution dropwise to intermediate A, keep the temperature at 5°C, raise the temperature to 68°C after the dropwise addition, stir and react for 18h, cool to minus 5°C after the reaction, and then add aluminum tetrahydrogen Lithium, stirring and reacting for 14 hours, and finally adding hydrochloric acid solution dropwise, controlling the dosage ratio of intermediate A, ethynylmagnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com