Solid-state battery pole piece as well as preparation method and application thereof

A solid-state battery and solid-state electrolyte technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of increasing the battery impedance of the pole piece and unsmooth ion conduction, so as to improve the safety performance of the battery and avoid the aftermath Disposal and recycling, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

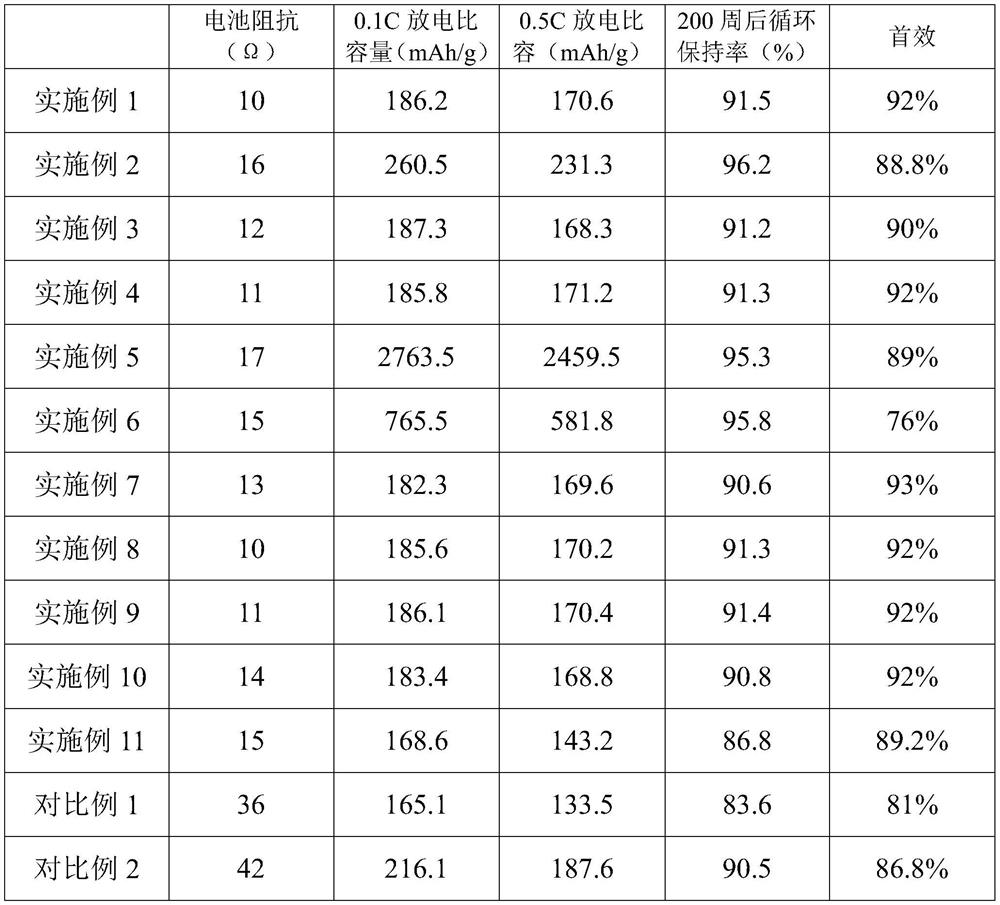

Examples

Embodiment 1

[0057] This embodiment provides a solid-state battery pole piece, which is a solid-state battery positive pole piece with a thickness of 70 μm, including a current collector, and an active material layer arranged on the surface of the current collector. The active material layer includes LiNi 0.8 co 0.1 mn 0.1 o 2 , carbon nanotubes and Li 3 InI 3 Br 3 , in the active material layer, LiNi 0.8 co 0.1 mn 0.1 o 2 The mass ratio is 65.2%, the carbon nanotube mass ratio is 2.2%, and the Li 3 InI 3 Br 3 The mass proportion is 32.6%.

[0058] This embodiment also provides a preparation method of the above-mentioned solid battery pole piece, and the preparation method specifically includes the following steps:

[0059] 6g LiNi 0.8 co 0.1 mn 0.1 o 2 , 0.2g carbon nanotubes, 3g Li 3 InI 3 Br 3 After stirring and mixing, the active material layer was prepared by rolling at 80° C., and the active material layer and the current collector were rolled to form a solid batte...

Embodiment 2

[0061] This embodiment provides a solid-state battery pole piece, which is a solid-state battery negative pole piece with a thickness of 120 μm, including a current collector, and an active material layer arranged on the surface of the current collector. The active material layer includes graphite, carbon nanotubes and Li 3 InI 3 Br 3 , in the active material layer, the graphite mass accounts for 66.3%, the carbon nanotube mass accounts for 2.1%, and the Li 3 InI 3 Br 3 The mass ratio is 31.6%.

[0062] This embodiment also provides a preparation method of the above-mentioned solid battery pole piece, and the preparation method specifically includes the following steps:

[0063] 6.3g of graphite, 0.2g of carbon nanotubes, 3g of Li 3 InI 3 Br 3 After stirring and mixing, the active material layer was prepared by rolling at 80° C., and the active material layer and the current collector were rolled to form a solid battery pole piece.

Embodiment 3

[0065] This embodiment provides a solid-state battery pole piece. Compared with Embodiment 1, the difference is that the active material layer includes LiNi 0.8co 0.1 mn 0.1 o 2 , acetylene black and Li 3 GaCl 3 f 3 , in the active material layer, LiNi 0.8 co 0.1 mn 0.1 o 2 The mass proportion is 52%, the mass proportion of acetylene black is 1%, and the Li 3 GaCl 3 f 3 The mass proportion is 35%, and the rest is Li 6 SP 5 Cl solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com