A method for 3D printing complex structures of low-temperature co-fired alumina ceramics with high solid content

An alumina ceramic, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of poor slurry stability, difficult to achieve high-speed, high-precision direct-write 3D printing, difficult to store for a long time, etc., to reduce shrinkage, Low sintering shrinkage and uniform shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

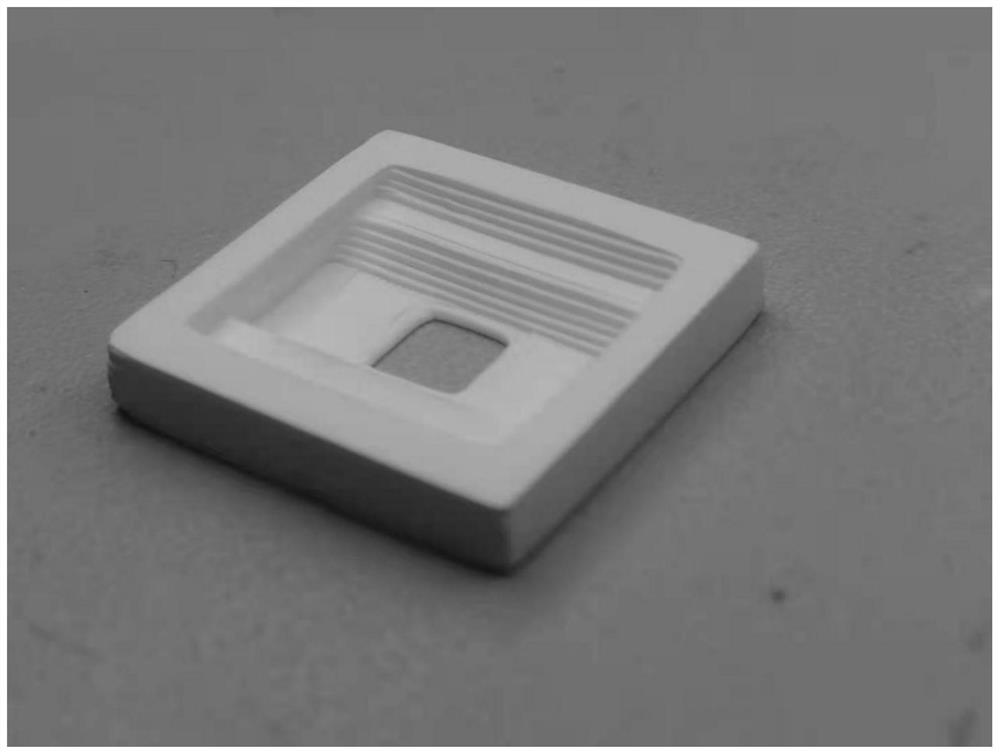

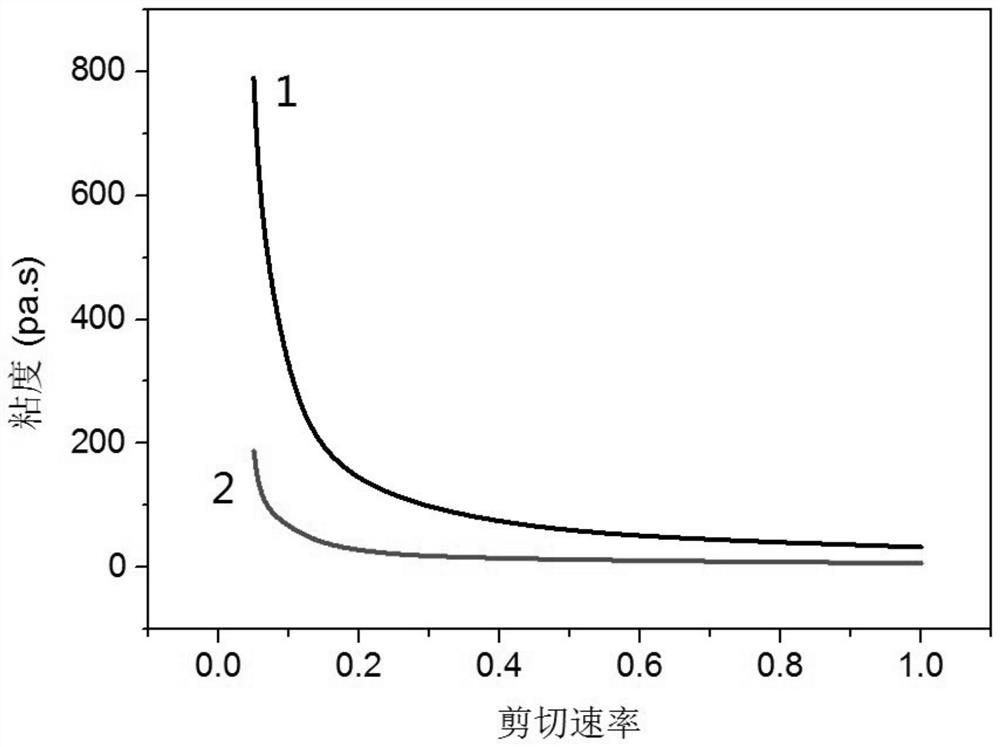

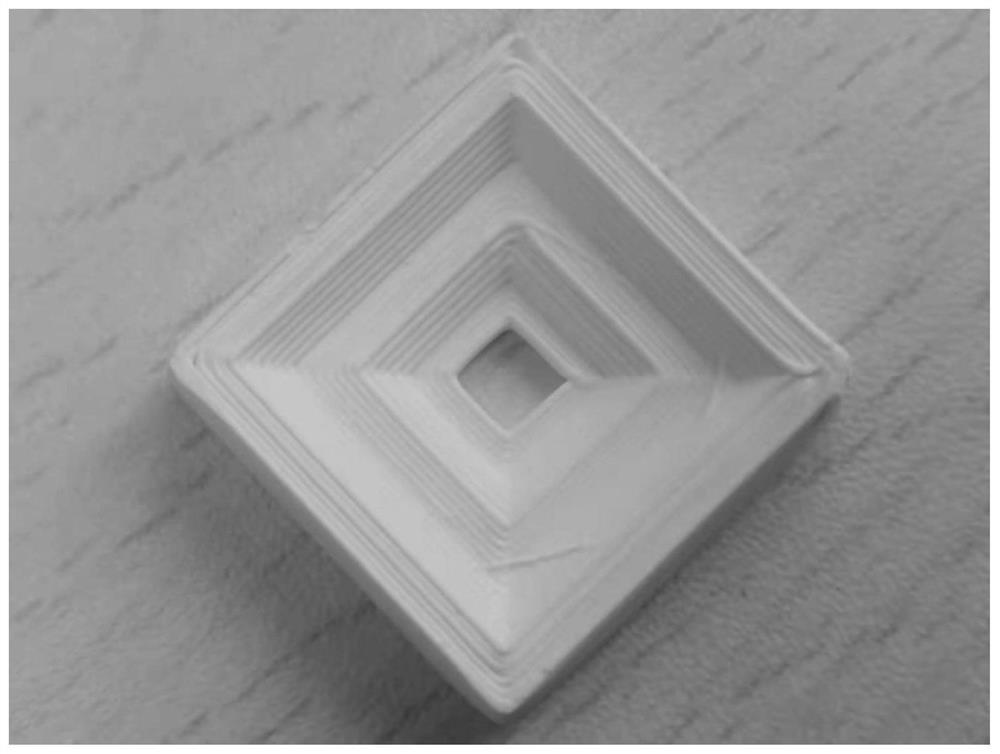

[0029] Specific implementation mode 1: This implementation mode is a method for 3D printing a complex structure of low-temperature co-fired alumina ceramics with high solid phase content, which is carried out according to the following steps:

[0030] 1. Weighing:

[0031] Weigh 4 to 8 parts of solvent, 0.5 to 1 part of dispersant, 0.5 to 1 part of surfactant, 0.5 to 1 part of binder, 0.5 to 5 parts of diluent, 2 parts to 4 parts of thixotropic agent, 60-88 parts of alumina powder, 1-20 parts of glass powder and 300-500 parts of absolute ethanol;

[0032] 2. Preparation of organic colloids:

[0033] Mix 4 to 8 parts of solvent, 0.5 to 1 part of dispersant and 0.5 to 1 part of surfactant and stir evenly, then add 0.5 to 1 part of binder, and in a temperature range of 50°C to 90°C Under certain conditions, heat and stir for 2h to 4.5h, then use vacuum defoaming to stir and mix evenly, then add 0.5 to 5 parts of diluent and 2 to 4 parts of thixotropic agent, use vacuum to defoa...

specific Embodiment approach 2

[0049] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the solvent described in step one is one or more mixtures in terpineol, ethyl acetate and butyl acetate; Described dispersant is Efka 110; The tensio-active agent described in step one is triton; The binding agent described in step one is ethyl cellulose, methyl cellulose, hydroxyethyl cellulose or Polyvinyl butyral; The thinner described in step one is N-ethylpyrrolidone, thinner BYK164 or thinner 4300; The thixotropic agent described in step one is castor oil; The oxidation described in step one The aluminum powder is a spherical particle with a particle diameter of 200nm-10μm; the glass powder described in step 1 is a spherical particle with a particle diameter of 500nm-10μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0050] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the vacuum degassing, stirring and mixing described in step 2 are uniform, specifically, when the vacuum degassing and stirring speed is 500r / min~2000r / min and Under the condition of vacuum degree of 30kPa~50kPa, vacuum degassing and stirring for 5min~20min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com