Non-animal-source chondroitin sulfate oligosaccharides and preparation method thereof

A technology of chondroitin sulfate and chondroitin sulfate, which is applied in the field of biomedicine and can solve the problems of the specific structure of chondroitin sulfate and the separation and preparation method of molecular weight oligosaccharides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Preparation of Escherichia coli K4 polysaccharide

[0053] Escherichia coli K4 polysaccharide was cultivated in a 15L fermenter, the seed medium was sodium chloride 10g / L, tryptone 10g / L, yeast extract 5g / L, the fermentation medium was glycerol 20g / L, (NH 4 ) 2 HPO 4 4 g / L, MgSO 4 ·7H 2 O 1.4g / L, citric acid 1.7g / L, KH 2 PO 4 13 g / L, trace element solution 10mL / L, feed medium: glycerol 500g / L, MgSO 4 ·7H 2 O20g / L, vitamin B 250mg / L, adjust pH=7.

[0054] The fermentation conditions are as follows: the inoculum amount is 10%, the temperature is 37° C., the pH value is 7, the rotation speed is 400-800 rpm, the dissolved oxygen content is controlled to be less than 30% during the fermentation process, and the cultivation is carried out for 48 hours.

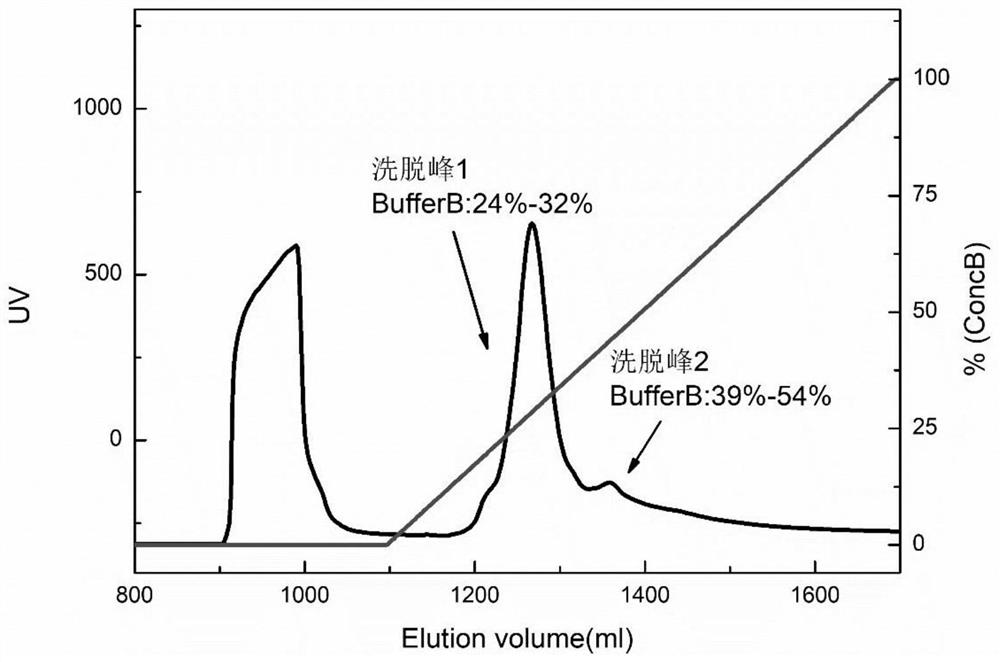

[0055] After the fermentation, the fermentation broth was centrifuged at 8000rpm for 15 minutes at low temperature, concentrated by boiling, alcohol precipitation, protein removal by savage reagent, dial...

Embodiment 2

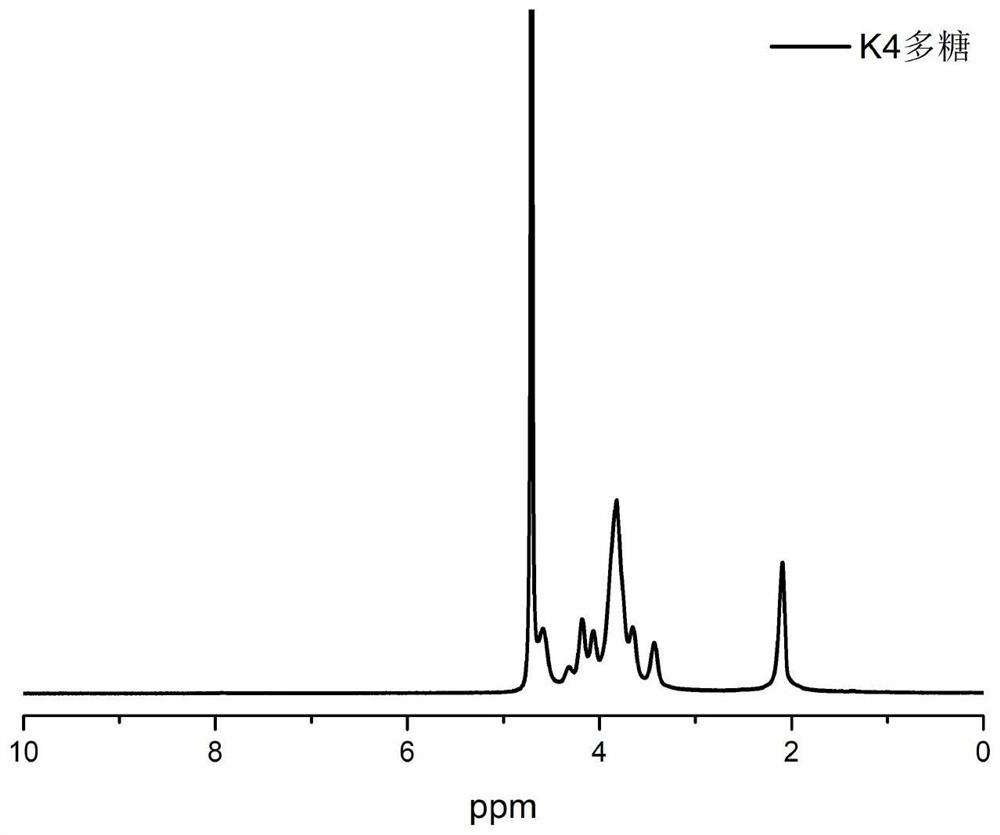

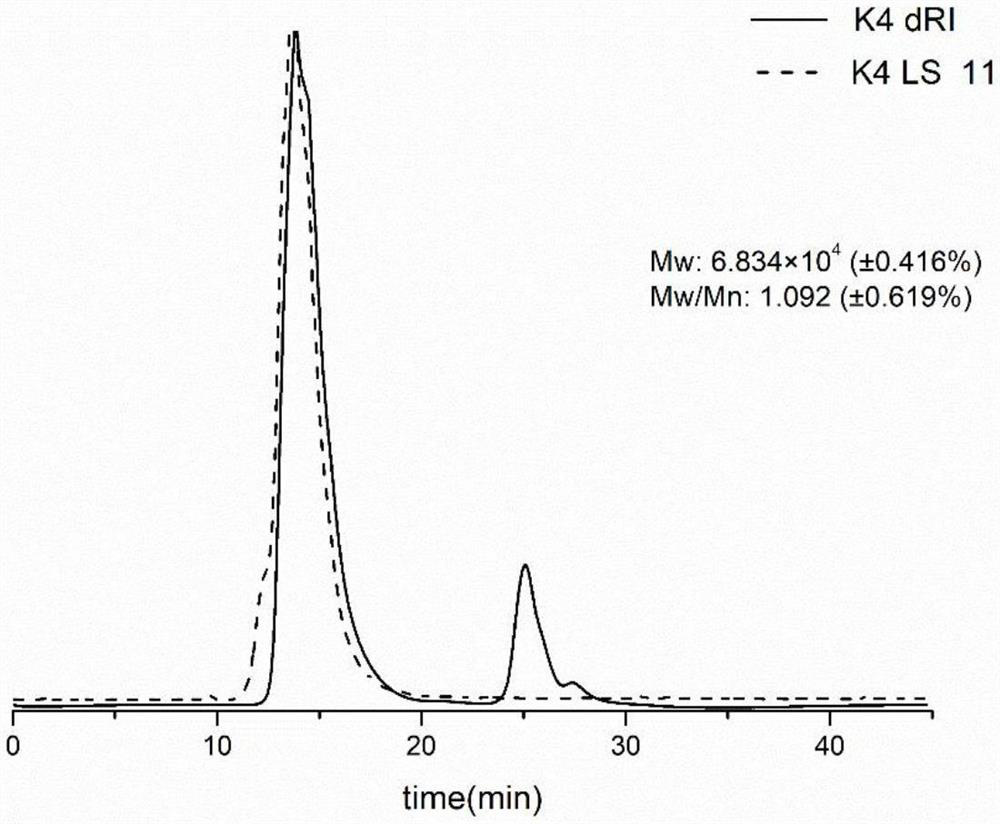

[0057] Embodiment 2: Preparation of Chondroitin DK4

[0058] Take 100mg of pure K4 polysaccharide and add 10mL of 0.025M trifluoroacetic acid (TFA), react at 100°C for 30min, cool to room temperature after the reaction, dialyze with distilled water in a 3500Da molecular weight cut-off dialysis bag for three days, and freeze-dry to obtain DK4. The hydrogen spectrum of DK4 is as follows Figure 4 Shown, indicating that the chemical structure of DK4 is chondroitin. SEC-MALLS results such as Figure 5 As shown, the molecular weight of DK4 is 27.7kDa, and the polydispersity index PDI is 1.24.

Embodiment 3

[0059] Embodiment 3: ChABC enzymatic preparation of chondroitin disaccharide

[0060] Weigh 12mg of purified chondroitin DK4 and dissolve it in 6mL of 100mM Tris, 150mM sodium acetate (pH 8.0) enzymolysis buffer, and place it in a constant temperature water bath at 37°C for 10 minutes to make it consistent with the enzymolysis reaction temperature. Then add 1 mL of purified chondroitin sulfate degrading enzyme ChABC to the substrate solution, and react in a constant temperature water bath for 24 hours. After the reaction, heat the metal bath at 100°C for 5 minutes to inactivate the enzyme, centrifuge at 8000r / min for 10 minutes, and remove the precipitate to obtain Chondroitin Oligosaccharide Mixture.

[0061] Pass the chondroitin oligosaccharide mixture obtained above through 30kDa, 10kDa, 3kDa, 1kDa ultrafiltration centrifuge tubes successively, centrifuge at 4°C and 4000g for 30min, and collect them. The main components are less than 1kDa and 1-3kDa, and concentrate by refr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com