Micro LED device for inhibiting SRH non-radiative recombination and preparation method

A non-radiation and device technology, which is applied in the field of micro-semiconductor light-emitting diodes and its preparation, can solve the problems of reducing the external quantum efficiency of the device, reducing the carrier concentration, increasing the leakage current of the device, etc., so as to improve the hole injection efficiency and the external quantum Efficiency, increasing the dielectric constant, and improving the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075]A Micro LED device that can suppress sidewall SRH non-radiative recombination.

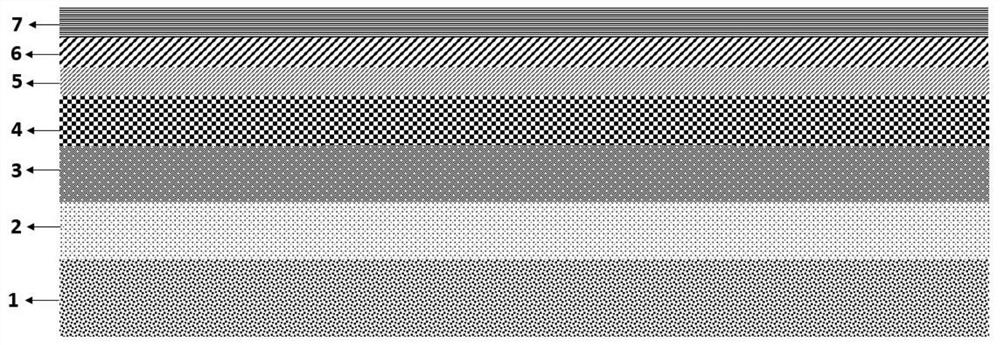

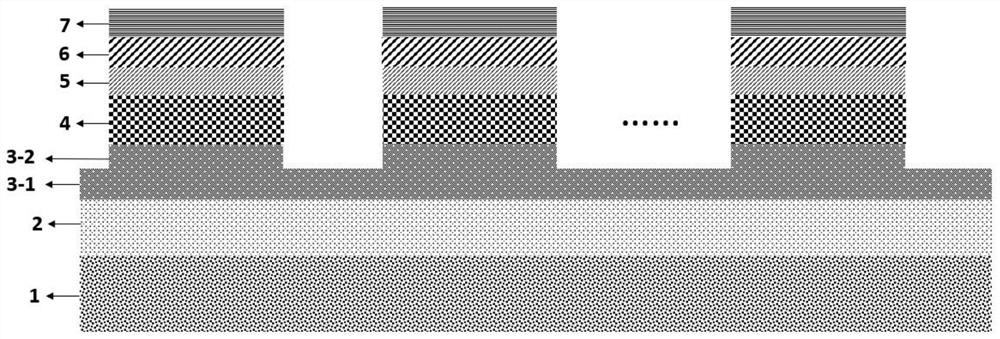

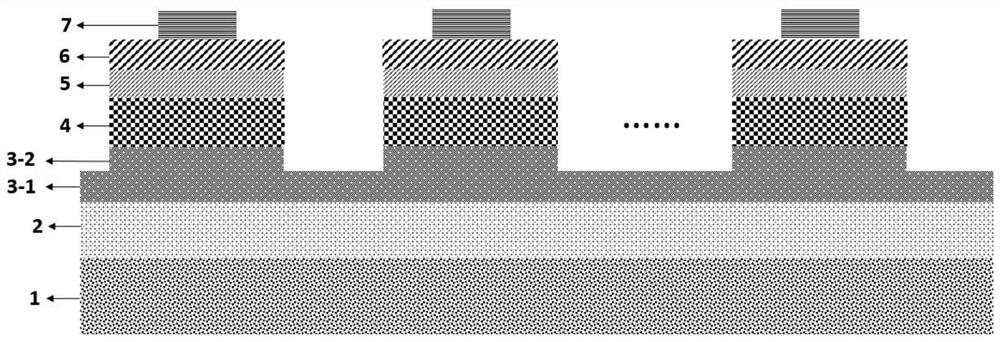

[0076] The Micro LED device includes in sequence along the epitaxial growth direction: sapphire substrate 1; buffer layer 2, made of intrinsic GaN, with a thickness of 1.5 μm; N-type semiconductor material layer 3, made of n-GaN, with a total thickness of 5 μm , wherein the size of the sapphire substrate is a circle with a diameter of 2 inches, and the N-type semiconductor material layer 3 is divided into a first N-type semiconductor material layer 3-1 and a second N-type semiconductor material layer 3- 2. On the first N-type semiconductor material layer 3-1, there are evenly distributed matrix second N-type semiconductor material layers 3-2 with a side length of 20 microns; the first N-type semiconductor material layer and the second N-type semiconductor material layer -type semiconductor material layers have a thickness of 3 μm and 2 μm, respectively;

[0077] The second N-type semiconduc...

Embodiment 2

[0090] Except that the substrate is a gallium nitride substrate, the photolithography technology is a holographic photolithography technology, and the insulating confinement layer is hafnium oxide, the others are the same as in the first embodiment.

Embodiment 3

[0092] Except that the substrate is an R-plane aluminum oxide single crystal substrate and an insulating confinement layer of silicon nitride, the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com