Automobile all-aluminum air heater and assembling method thereof

An assembly method and heater technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of affecting installation and product appearance, frequent leakage of heat dissipation pipes, and affecting the brazing pass rate, etc. Problems, to avoid heat stress deformation, reduce leakage, improve the effect of brazing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with the accompanying drawings of the present invention in embodiments, the technical solutions in the embodiments of the present invention are clearly and completely described, obviously, the described embodiments are part of the embodiments of the present invention rather than all embodiments. Based on the embodiments of the present invention, all other embodiments of ordinary skill in the art without creative efforts shall, should fall within the scope of the present invention.

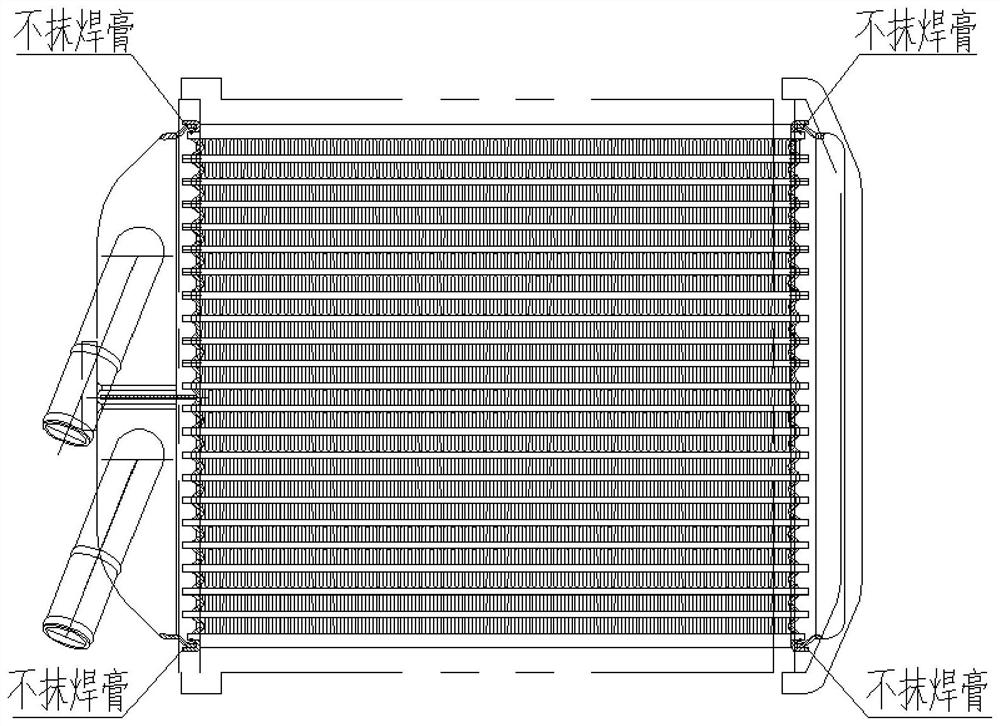

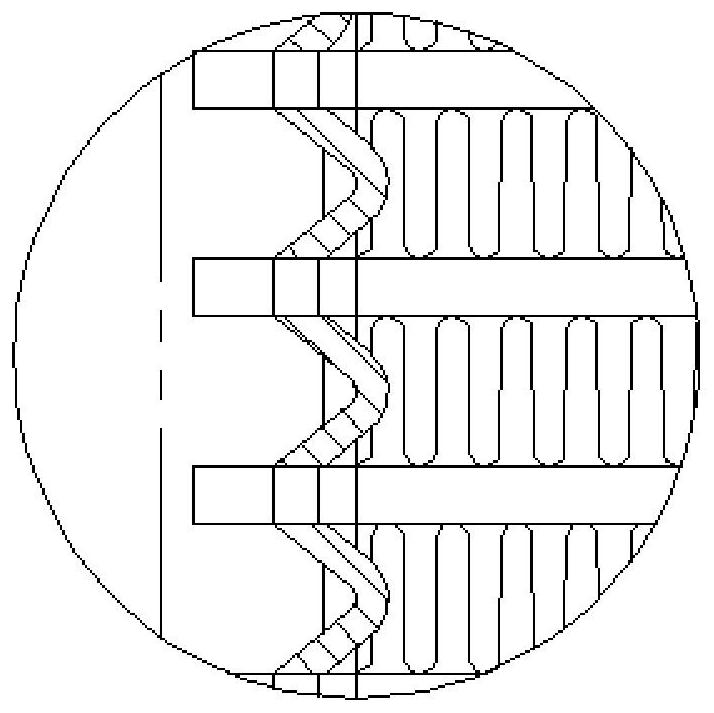

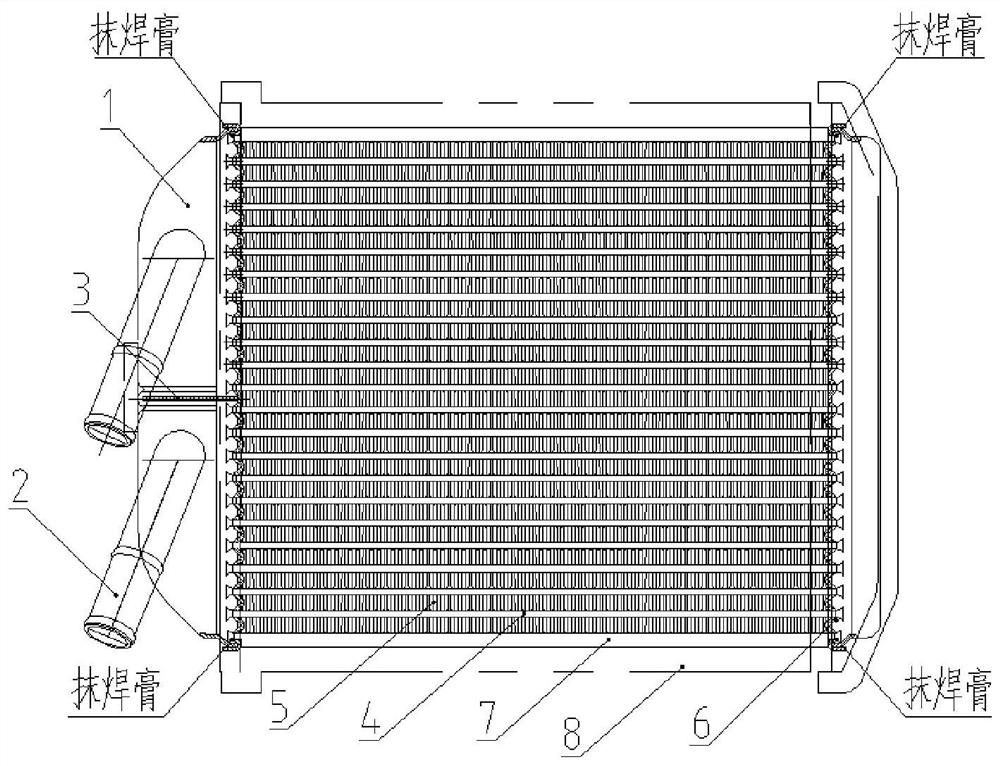

[0036] Aluminum heater core of an automobile, such as the structure image 3 Shown, comprises a water chamber 1, bend 2 and the core, the crimping of the water chamber core 1, 2 is mounted on the water trap chamber 1, the core 4 and main heat pipe comprises a sheet 6, and the primary heat pipe 4 sheet 6 is connected, at both ends of the heat pipe 4 are provided with flared, the water chamber 1 is equipped with 3 inserts.

[0037] Further comprising a core plate 7, the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com