Modified foaming polyurethane and preparation method thereof

A foamed polyurethane and modified technology, applied in the field of polyurethane, can solve the problems of severe temperature requirements and failure, and achieve the effect of increasing uniform dispersion and increasing nucleation points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

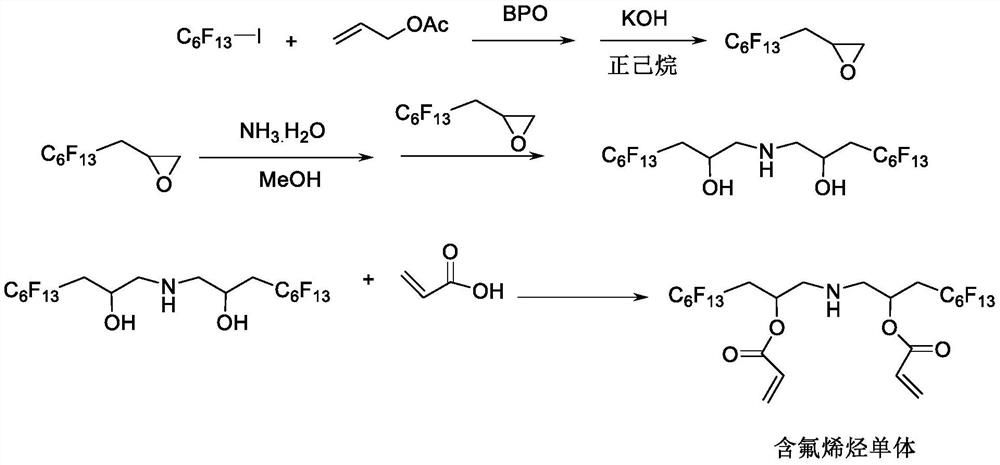

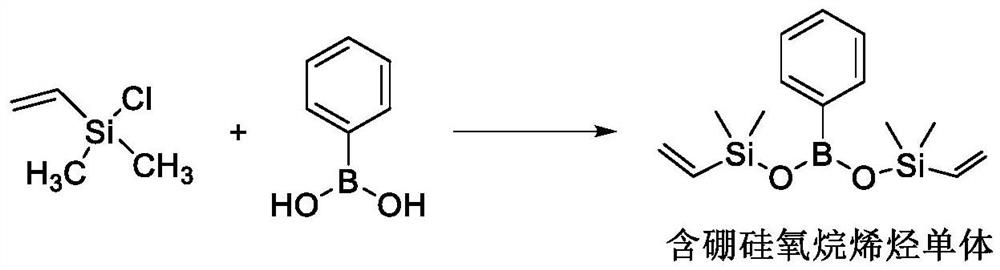

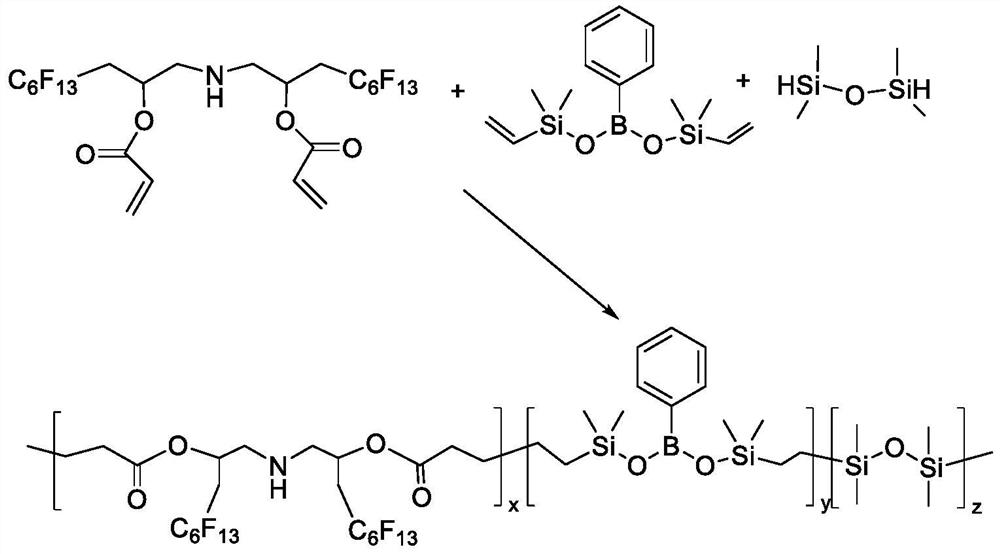

[0035] Modified polyborosiloxane is made by the following steps:

[0036]X1. Add 0.1mol perfluorohexyl iodide and 0.1mol allyl acetate into a four-necked flask equipped with a condenser, thermometer, drying tube, and stirring paddle, heat to 93°C for 3 minutes, and add a mass of perfluorohexyl iodide 0.1% benzoyl peroxide by the mass of alkane, after the reaction heats up rapidly to 150°C, continue the reaction for 30min, and when the reaction temperature drops to 80°C, add 100mL of n-hexane and 1% of the mass of perfluorohexyl iodane % potassium hydroxide, reacted for 6h, cooled and filtered, washed with n-hexane, and the filtrate was distilled under reduced pressure to collect 77°C / 40mmHg fractions to obtain 3-perfluoro-n-hexyl-1,2-epoxypropane; add to a completely sealed flask 0.1mol 3-perfluoro-n-hexyl-1,2-epoxypropane, 20mL methanol and 80mL ammonia water with a mass fraction of 28%, stirred for 12 hours, rotary evaporation to remove ammonia water and methanol, and then a...

Embodiment 2

[0040] Modified polyborosiloxane is made by the following steps:

[0041] X1. Add 0.1mol perfluorohexyl iodide and 0.13mol allyl acetate into a four-necked flask equipped with a condenser, thermometer, drying tube, and stirring paddle, heat to 93°C for 3 minutes, and add a mass of perfluorohexyl iodide 0.3% benzoyl peroxide by the mass of alkane, after the reaction heats up rapidly to 150°C, continue the reaction for 30min, and when the reaction temperature drops to 80°C, add 200mL of n-hexane and 5% of the mass of perfluorohexyl iodane. % potassium hydroxide, reacted for 6h, cooled and filtered, washed with n-hexane, and the filtrate was distilled under reduced pressure to collect 80°C / 40mmHg fractions to obtain 3-perfluoro-n-hexyl-1,2-epoxypropane; add 0.1mol 3-perfluoro-n-hexyl-1,2-epoxypropane, 40mL methanol and 150mL ammonia water with a mass fraction of 28%, stirred for 12 hours, rotary evaporation to remove ammonia water and methanol, and then added 0.1mol 3-perfluoropr...

Embodiment 3

[0045] Composite blowing agents are made through the following steps:

[0046] S1. After mixing the mixed solution of cetylamine, isopropanol and deionized water evenly, add ammonia water with a mass fraction of 30%, under stirring at room temperature, add ethyl orthosilicate, after stirring for 1min, stop stirring and let it stand for 1d , filtered, washed with ethanol and distilled water, and roasted in vacuum at 630°C for 6h to obtain mesoporous silica; wherein, the ratio of hexadecylamine, ammonia water, and ethyl orthosilicate was 1g: 1.5mL: 5mL, iso The volume ratio of isopropanol to deionized water in the mixed solution of propanol and deionized water is 1:8; immerse the mesoporous silica in the double salt solution for 1 hour, then take out the mesoporous silica and bake it at 320°C for 2 hours. Take out the mesoporous silica, wash it with water until there is no chloride ion, and dry it to obtain the treated mesoporous silica, wherein the double salt solution is compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com