Preparation method of polyimide porous membrane containing amidoxime group

A polyimide and amidoxime-based technology, applied in the field of special polymer materials, can solve problems such as poor radiation resistance, and achieve the effects of simple and practical method, simple production operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

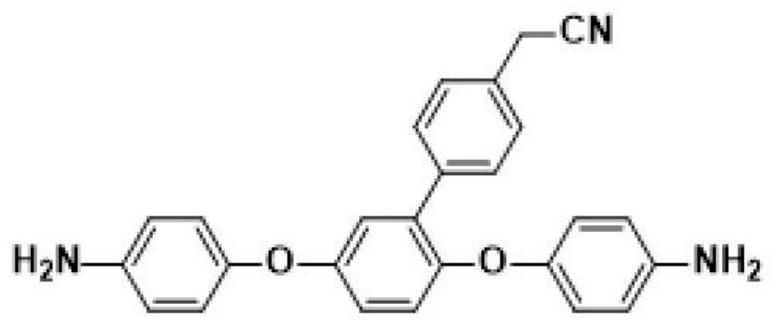

[0016] (1) Under the protection of a nitrogen atmosphere, add 2.42g of diamine monomer and 100g of N,N-dimethylacetamide to the reaction flask to form a diamine solution with a concentration of 2wt%, and then add 3.2g of 3,3',4,4'-benzophenonetetraacid dianhydride was stirred and reacted for 12h at room temperature to obtain a polyamic acid solution, wherein 0.82g (20mol%) of the diamine contained figure 1 The diamine of the shown structure, other diamines are 1.6g (80mol%) 4,4'-diaminodiphenyl ether;

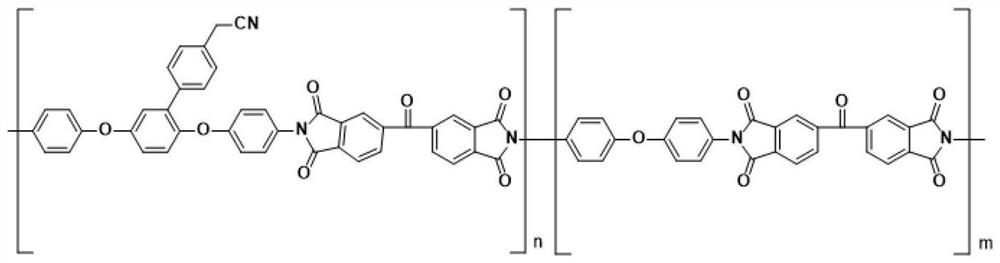

[0017] (2) Under a nitrogen atmosphere, heat the reaction solution in step (1) to 180°C, and heat and stir the reaction for 12 hours at the same time, so that the imidization reaction occurs and the water generated by the water reaction is removed, and then the reaction solution is poured into 550mL of water , precipitated, filtered, and dried to obtain polyimide powder, whose structural formula is as attached figure 2 shown;

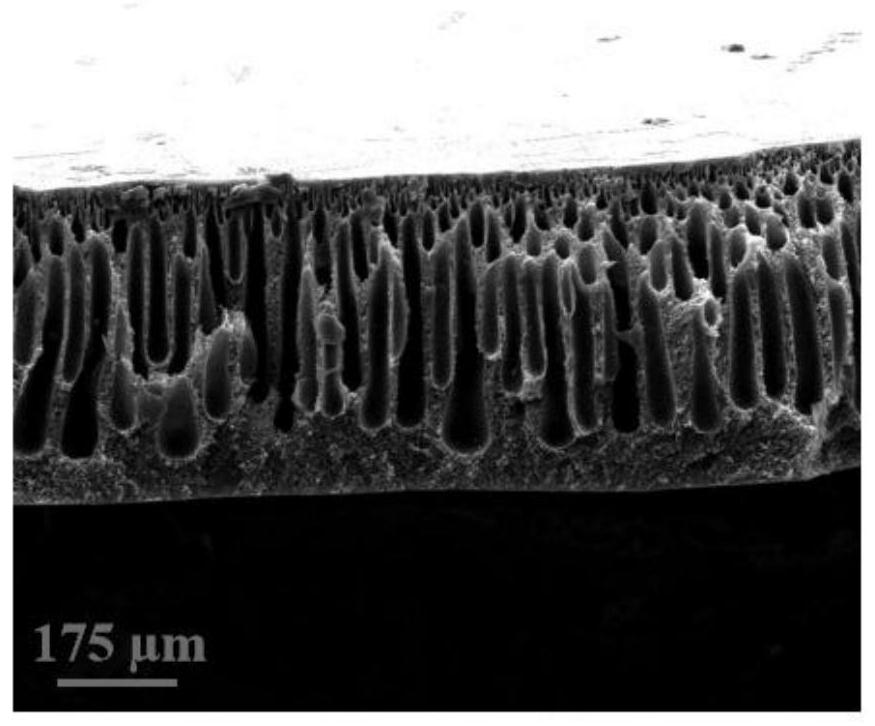

[0018] (3) Add 1 g of polyimide in step (2) to ...

Embodiment 2

[0021] (1) Under the protection of a nitrogen atmosphere, add 4.84g of diamine monomer and 100g of N,N-dimethylacetamide to the reaction flask to form a diamine solution with a concentration of 4wt%, and then add 6.4g of 3,3',4,4'-benzophenonetetraacid dianhydride, stirred and reacted for 12h at room temperature to obtain a polyamic acid solution, wherein the diamine contained 1.64g (20mol%) of figure 1 The diamine of the shown structure, other diamines are 3.2g (80mol%) 4,4'-diaminodiphenyl ether;

[0022] (2) consistent with embodiment 1 step (2);

[0023] (3) consistent with embodiment 1 step (3);

[0024] (4) Consistent with step (4) of Example 1, its adsorption capacity for uranium reaches 135 mg / g.

Embodiment 3

[0026] (1) Under the protection of a nitrogen atmosphere, add 2.42g of diamine monomer and 100g of N,N-dimethylacetamide to the reaction flask to form a diamine solution with a concentration of 2wt%, and then add 2.2 g of pyromellitic anhydride, stirred and reacted for 12 h at room temperature to obtain a polyamic acid solution, wherein 0.82 g (20 mol%) of diamines with attached figure 1 The diamine of the shown structure, other diamines are 1.6g (80mol%) 4,4'-diaminodiphenyl ether;

[0027] (2) consistent with embodiment 1 step (2);

[0028] (3) consistent with embodiment 1 step (3);

[0029] (4) Consistent with step (4) of Example 1, its adsorption capacity for uranium reaches 142mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com