Phosphorus removal material and preparation method thereof

A technology for raw materials and equipment, applied in the field of phosphorus removal materials and their preparation, to achieve the effects of improving adsorption performance, increasing stability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

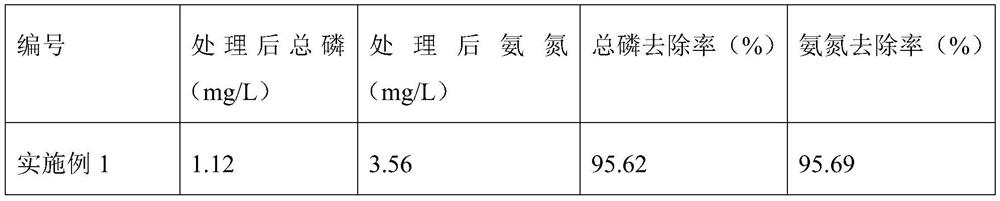

Embodiment 1

[0032] Place natural microcrystalline graphite (average particle size of 50 μm), balls (diameter of 10-16 mm) and water in a zirconia ball mill tank at a mass ratio of 1:15:5, and grind the ball on a planetary ball mill at 500 r / min Rotate the ball mill for 24 hours, then take it out and dry it in an oven, pass through a 200-mesh sieve to obtain graphite powder.

[0033] Dissolve the obtained graphite powder in 15wt% copper sulfate solution according to the solid-to-liquid ratio of 1:8, and ultrasonically treat it at 100KHz for 5h, then filter and wash, and calcinate the obtained solid at 900°C for 2h at high temperature, and then cool it down to room temperature to give a solid product.

[0034] Mix the obtained solid product with polystyrene and polyvinyl chloride at a mass ratio of 1:1:1 and undergo a crosslinking reaction under the action of aluminum chloride. After the reaction is completed, the product is dried and placed in twin-screw extrusion Extrusion molding in the...

Embodiment 2

[0036] Put natural flake graphite (average particle size of 50 μm), grinding balls (diameter of 10-16 mm) and water in a zirconia ball mill tank at a mass ratio of 1:15:5, and rotate at 500 r / min on a planetary ball mill Ball mill for 24 hours, then take it out and dry it in an oven, pass through a 200-mesh sieve to obtain graphite powder.

[0037] Dissolve the obtained graphite powder in 15wt% copper sulfate solution according to the solid-to-liquid ratio of 1:5, and ultrasonically treat it at 100KHz for 5h, then filter and wash, and calcinate the obtained solid at 900°C for 2h, and then cool it down to room temperature to give a solid product.

[0038] Mix the obtained solid product with polystyrene and polyvinyl chloride at a mass ratio of 1:0.5:0.5 and undergo a crosslinking reaction under the action of aluminum chloride. After the reaction, the product is dried and placed in twin-screw extrusion Extrusion molding in the machine, the rotation speed of the twin-screw extru...

Embodiment 3

[0040] Put natural spherical graphite (average particle size of 50 μm), balls (diameter of 10-16 mm) and dodecane in a zirconia ball mill jar at a mass ratio of 1:15:5, and place them on a planetary ball mill at 500 r / Min speed ball milling for 24 hours, then take it out and dry it in an oven, pass through a 200-mesh sieve to obtain graphite powder.

[0041] Dissolve the obtained graphite powder in 15wt% copper sulfate solution according to the solid-to-liquid ratio of 1:10, and ultrasonically treat it at 100KHz for 5h, then filter and wash, and calcinate the obtained solid at 900°C for 2h at high temperature, and then cool it down to room temperature to give a solid product.

[0042] The obtained solid product is mixed with polystyrene and polyvinyl chloride at a mass ratio of 1:0.8:1 and cross-linked under the action of aluminum chloride. After the reaction is completed, the product is dried and placed in twin-screw extrusion Extrusion molding in the machine, the rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com