High-flux photo-thermal preparation method and application of defect-adjustable metal oxide

An oxide, high-throughput technology, applied in chemical instruments and methods, catalyst activation/preparation, titanium oxide/hydroxide, etc., can solve the problem of low light utilization rate of metal oxides, uncontrollable defect content, and harsh synthesis conditions and other problems, to achieve the effect of improving utilization efficiency and photocatalytic activity, good photogenerated carrier separation ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 50mg of titanium dioxide and ultrasonically disperse it in 40mL of deionized water and 10mL of glycerol to obtain a suspension, place the obtained suspension in a closed and heat-retaining reactor for 30min vacuum treatment; then use a xenon lamp with a light intensity of 15sun to - Irradiate the suspension with full spectrum of visible-infrared light for 180 minutes. The temperature of the suspension in the reactor spontaneously increased and maintained at 90 °C under the high-throughput concentrated light irradiation conditions. After the reactor is naturally cooled to room temperature, the suspension is centrifuged, washed with deionized water and vacuum-dried at room temperature to finally obtain titanium dioxide containing defects.

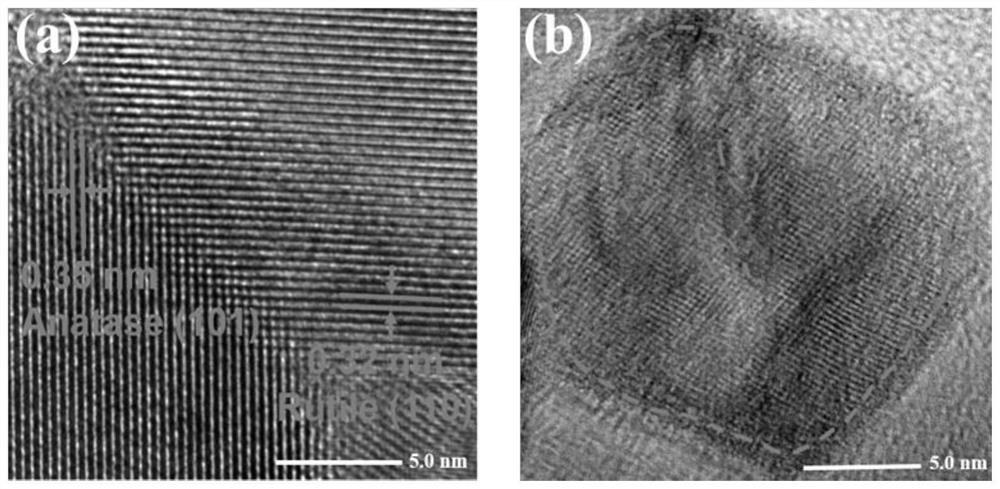

[0029] figure 1 TiO 2 and titanium dioxide containing defects (TiO 2-x -15), it can be seen that the color of the suspension changes from white to blue under high-throughput concentrated light irradiation, which is usually attr...

Embodiment 2

[0034] Effect of light intensity on defect content in titanium dioxide:

[0035]Take 50mg of titanium dioxide and ultrasonically disperse it in 40mL of deionized water and 10mL of glycerol to obtain a suspension, place the obtained suspension in a closed and insulated reactor for vacuum treatment for 30min; then use xenon lamps with a light intensity of 10sun and 5sun respectively , and irradiate the suspension for 180 min with the full spectrum of ultraviolet-visible-infrared light. The temperature of the suspension in the reactor spontaneously increased under 10sun and 5sun concentrated light irradiation and maintained at 79°C and 70°C, respectively. After the reactor was naturally cooled to room temperature, the suspension was centrifuged, washed with deionized water and vacuum-dried at room temperature to finally obtain defect-containing titanium dioxide TiO 2-x -10 and TiO 2-x -5.

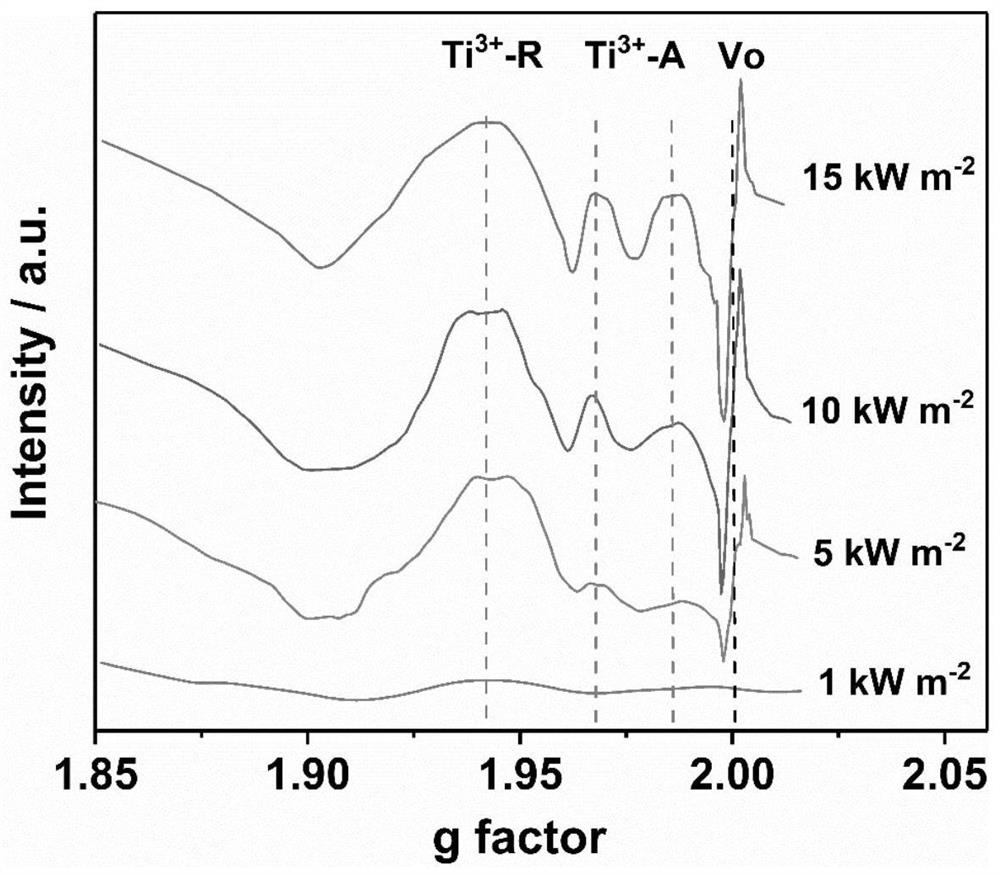

[0036] Depend on figure 2 It can be seen that the oxygen vacancies in titanium dioxid...

Embodiment 3

[0038] The effect of light time on the content of defects in titanium dioxide:

[0039] Take 50mg of titanium dioxide and ultrasonically disperse it in 40mL of deionized water and 10mL of glycerol to obtain a suspension, place the obtained suspension in a closed and heat-retaining reactor for 30min vacuum treatment; then use a xenon lamp with a light intensity of 15sun to - Irradiate the suspension with full spectrum of visible-infrared light for 120 min and 60 min, respectively. After the reactor is naturally cooled to room temperature, the suspension is centrifuged, washed with deionized water, and vacuum-dried at room temperature to finally obtain titanium dioxide with different defect contents.

[0040] Depend on Figure 6 It can be seen that the oxygen vacancies in titanium dioxide and Ti 3+ The content of both increases with the increase of the light time, indicating that the content of defects in titanium dioxide can also be effectively controlled by adjusting the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com