Cutting balloon with flexible cutting device

A technology for cutting balloons and cutting devices, which is applied in the fields of endoscopic cutting instruments, medical science, surgery, etc. It can solve the problems of narrowing the scope of use, weak support and poor passability of folding or helical structure cutting, and achieve the function of avoiding cutting Structural failure or detachment, preventing damage to the vessel wall, and improving the safety of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

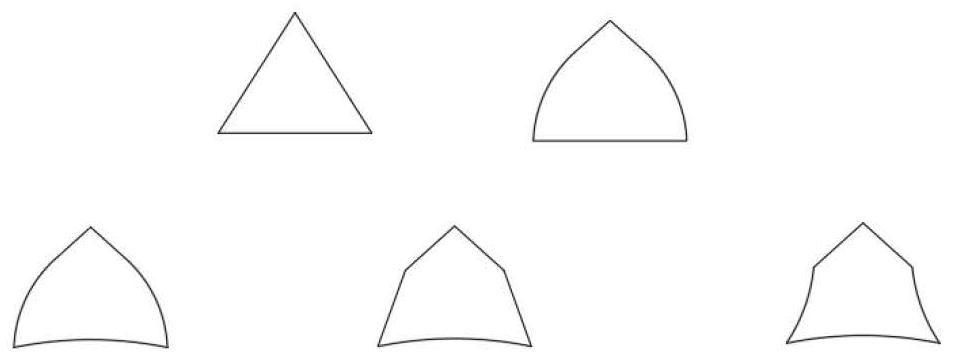

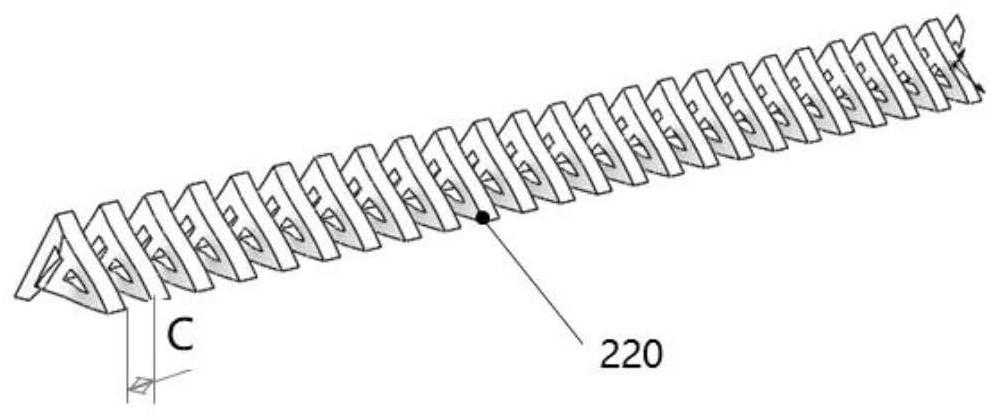

[0073] Such as figure 1 , Figure 7 As shown, the flexible cutting device 200 of the present invention consists of a cutting functional structure 220 and a flexible functional structure 210, and is installed on the balloon body 100. The 200 flexible cutting device has a width of 1mm, a height of 0.4mm, and a length of 60mm; the 220 cutting functional structure is a jagged nickel-iron alloy T-shaped elastic structure with a width of 0.6mm, a height of 0.4mm, a length of 55mm, and a thickness of 0.35mm. The width of the sawtooth is 3mm, the distance between adjacent teeth is 0.8mm, such as Figure 6 As shown; the material of the 210 flexible functional structure is silica gel covering the surface of the cutting functional structure. The width of the silicone is 0.5mm, the height is 0.4mm, and the length is 58mm. The outer surface constitutes a cutting balloon, and the tensile strength measured between the flexible cutting structure and the balloon body is 6.8N / mm after fixatio...

Embodiment 2

[0077] Such as figure 1 and Figure 9 As shown, the flexible cutting device 200 of the present invention consists of a cutting functional structure 220 and a flexible functional structure 210, and is installed on the balloon body 100. The 200 flexible cutting device has a width of 1.5mm, a height of 0.8mm, and a length of 80mm; the 220 cutting functional structure is a nickel-iron alloy triangular wire-wound elastic structure with a width of 1.0mm, a height of 0.82mm, and a length of 75mm. Figure 10 , Figure 11 Medium 220, the diameter of the winding wire is 0.06, and the gap between the winding wires is 0.2mm; firstly, the 220 cutting functional structure is evenly installed on the outer surface of the 100 balloon body, and then the 220 is cut with 210 flexible functional structure, specifically acrylic anaerobic adhesive The functional structure was filled and vacuum cured for more than 3 minutes, so that the flexible cutting device was fixed on the outer surface of the ...

Embodiment 3

[0081] Such as figure 1 and Figure 9 As shown, the flexible cutting device 200 of the present invention consists of a cutting functional structure 220 and a flexible functional structure 210, and is installed on the balloon body 100. 200 flexible cutting device width 0.8mm, height 0.4mm, length 20mm, section such as Figure 11 As shown; 220 cutting function structure is a stainless steel triangular pipe with a thickness of 0.06mm, which is cut into a width of 0.5mm, a height of 0.39mm, and a length of 17mm, and the gap is 0.02mm. image 3 The above-mentioned spring structure; the material of the flexible functional structure is silica gel with good elasticity and there is a triangular gap in the middle. The gap is an equilateral triangle with a height of 0.15 mm. The outer surface of the balloon constitutes a cutting balloon, and the tensile strength between the flexible cutting structure and the balloon body is measured to be 5.8N / mm after fixation 2 .

[0082] First pus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com