Heat treatment method and heat treatment apparatus

A heat treatment method and heat treatment device technology, applied in the direction of electric heating device, ohmic resistance heating device, measuring device, etc., can solve the problem that uniform device performance cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

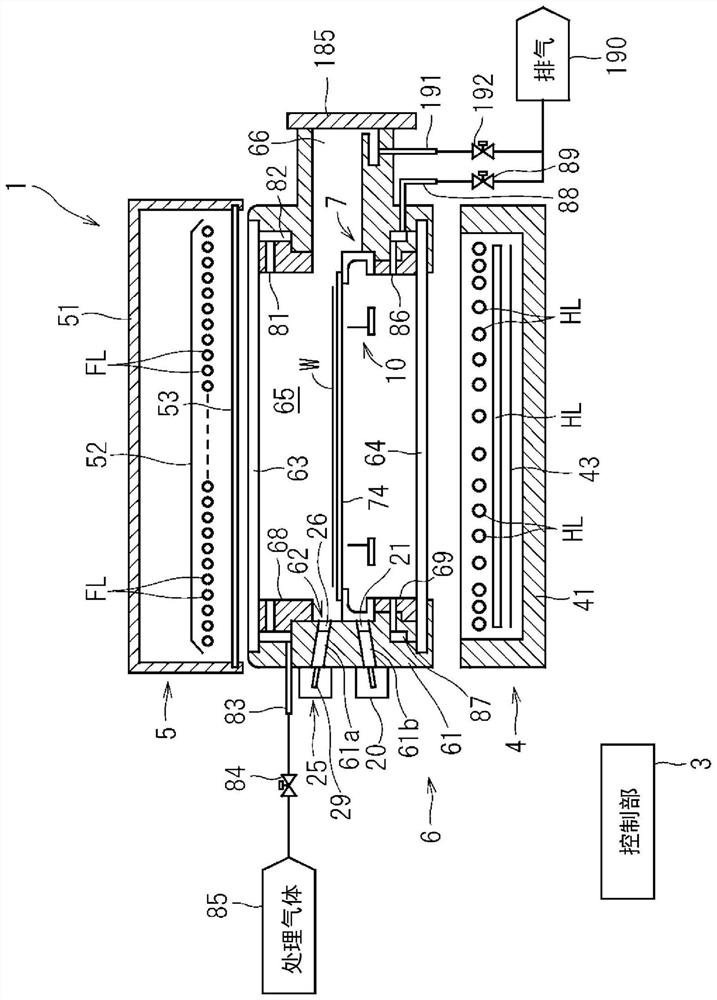

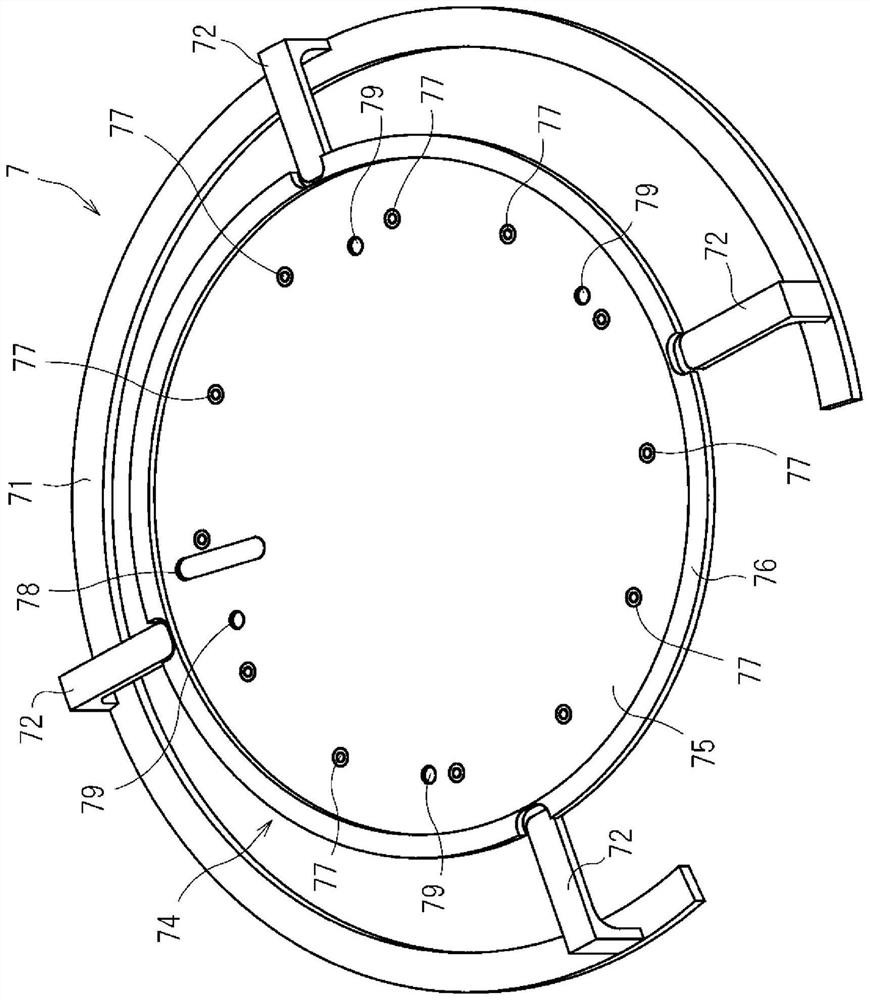

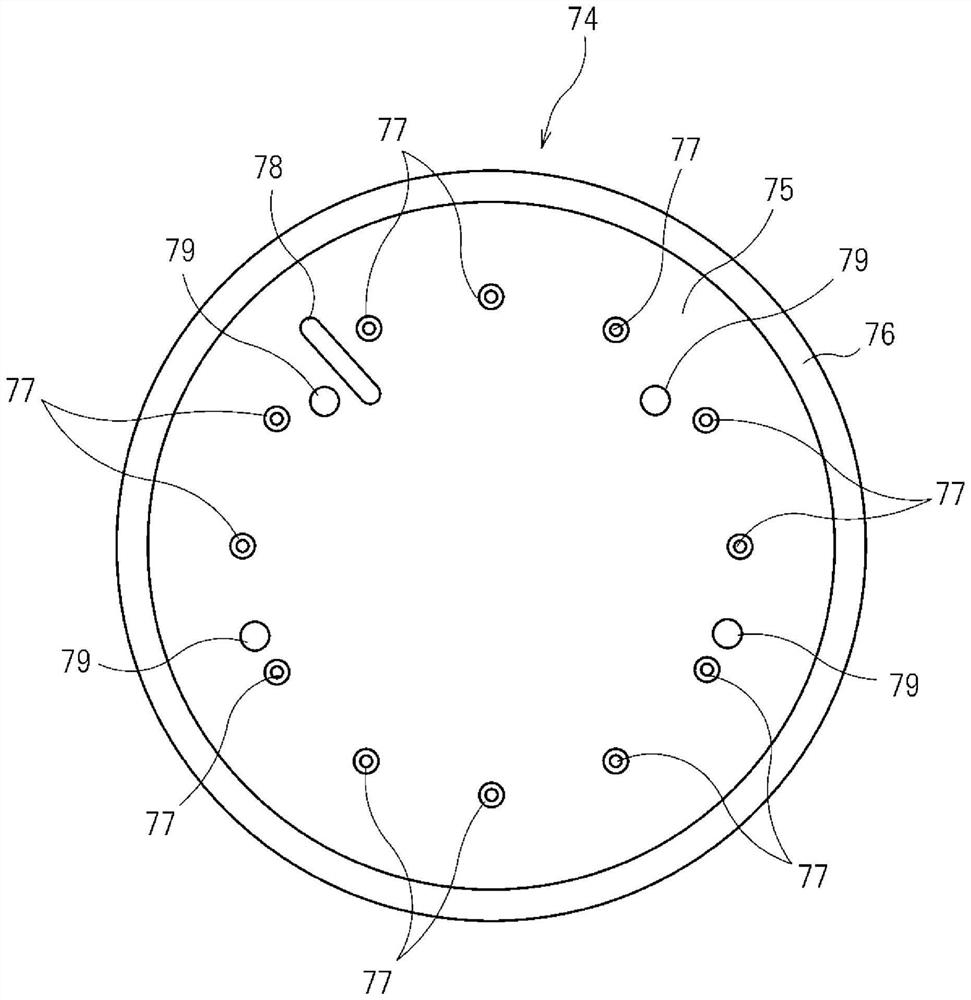

[0045]figure 1 It is a longitudinal sectional view showing the configuration of the heat treatment apparatus 1 of the present invention. figure 1 The heat treatment apparatus 1 is a flashlamp annealing apparatus that heats a semiconductor wafer W as a substrate by flash irradiation on a disk-shaped semiconductor wafer W. The size of the semiconductor wafer W to be processed is not particularly limited, and is, for example, φ300 mm or φ450 mm (φ300 mm in this embodiment). Impurities are implanted into the semiconductor wafer W before being loaded into the heat treatment apparatus 1 , and the implanted impurities are activated by heat treatment in the heat treatment apparatus 1 . also, figure 1 In each of the following drawings, the size or number of each part is exaggerated or simplified as necessary for easy understanding.

[0046] The heat processing apparatus 1 is provided with: the chamber 6 which accommodates the semiconductor wafer W, the flash heating part 5 which buil...

no. 2 Embodiment approach >

[0116] Next, a second embodiment of the present invention will be described. The configuration of the heat treatment apparatus of the second embodiment is completely the same as that of the first embodiment. In addition, the processing procedure of the semiconductor wafer W of the second embodiment is also substantially the same as that of the first embodiment. In the first embodiment, the current supply to the flash lamp FL is stopped when the actual measured value of the surface temperature of the semiconductor wafer W reaches the target temperature T2, but in the second embodiment, it is estimated that the surface temperature of the semiconductor wafer W reaches the target temperature T2. time, and the current supply to the flash lamp FL is stopped at the predetermined time.

[0117] Figure 14 It is a flowchart which shows the processing procedure of the heat processing apparatus 1 of 2nd Embodiment. Figure 14 Steps S21 to S23 with Figure 10 Steps S11 to S13 are the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com