A heat-shrinkable tube heating device

A heating device and heat-shrinkable tube technology, which is applied in the assembly/disassembly of contact parts, circuit/collector parts, electrical components, etc., can solve the problems of low manual operation efficiency, poor heating quality of heating tubes, and heating damage of wiring harnesses, etc. problems, to achieve the effect of reducing labor intensity, improving heating quality, and heating evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

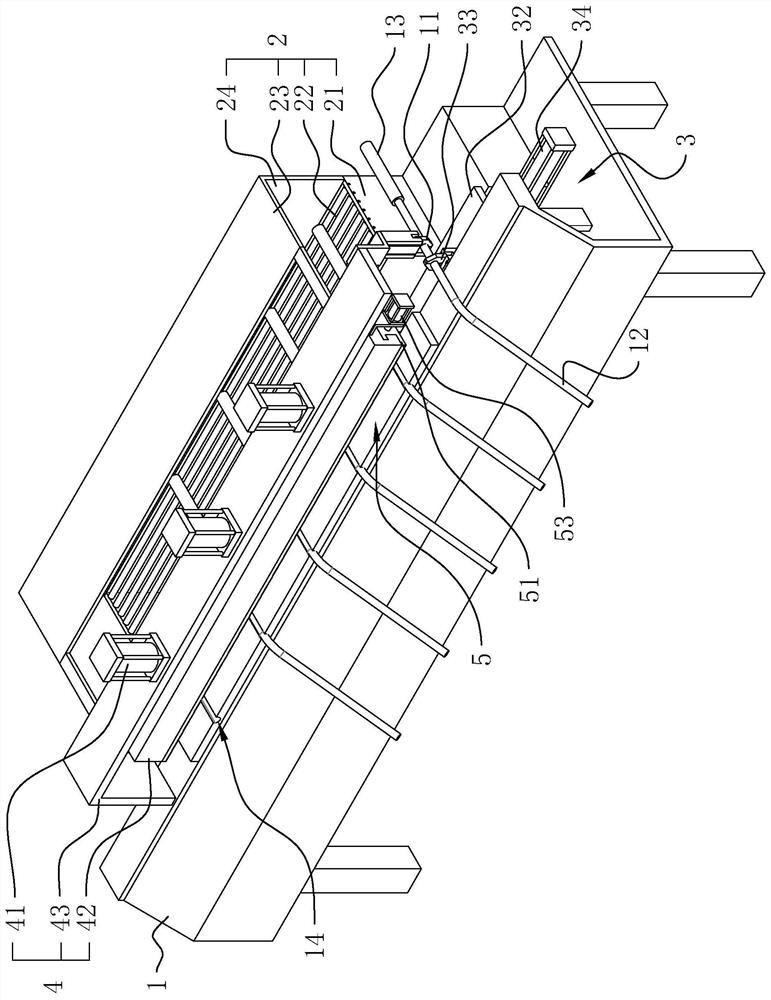

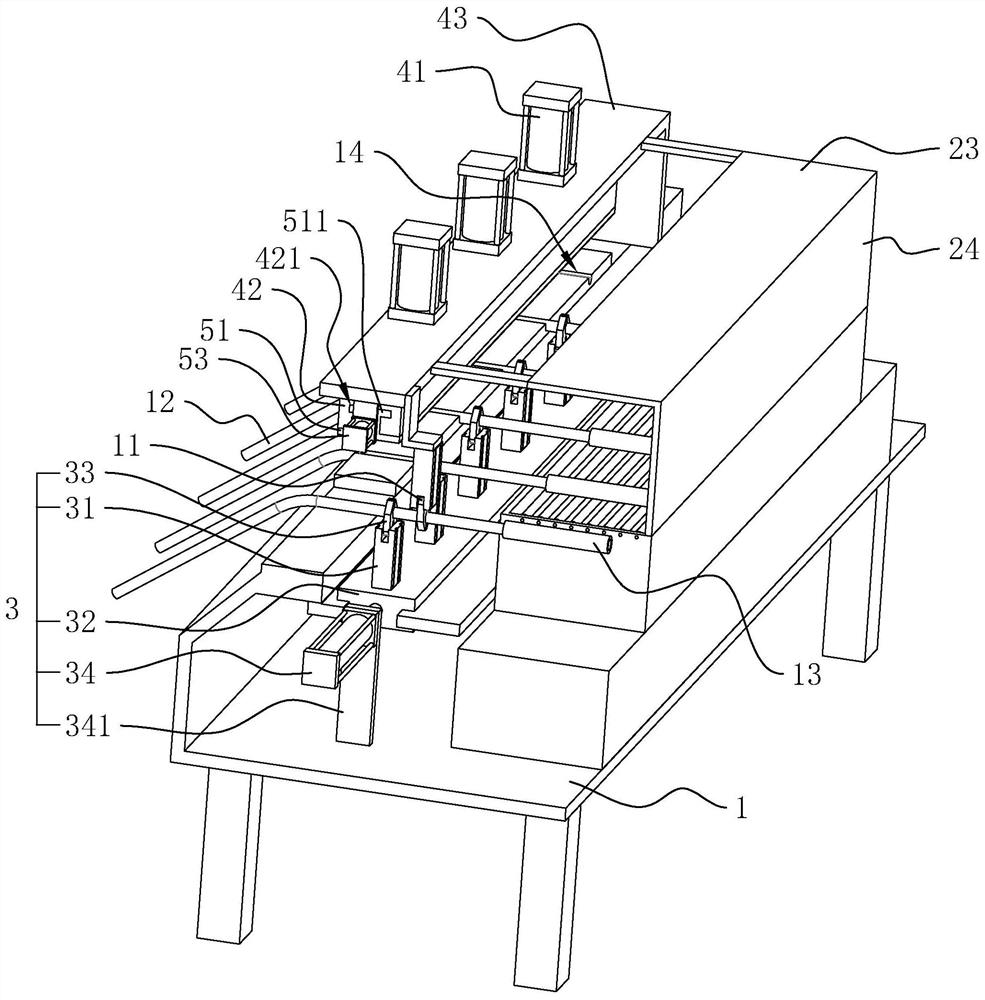

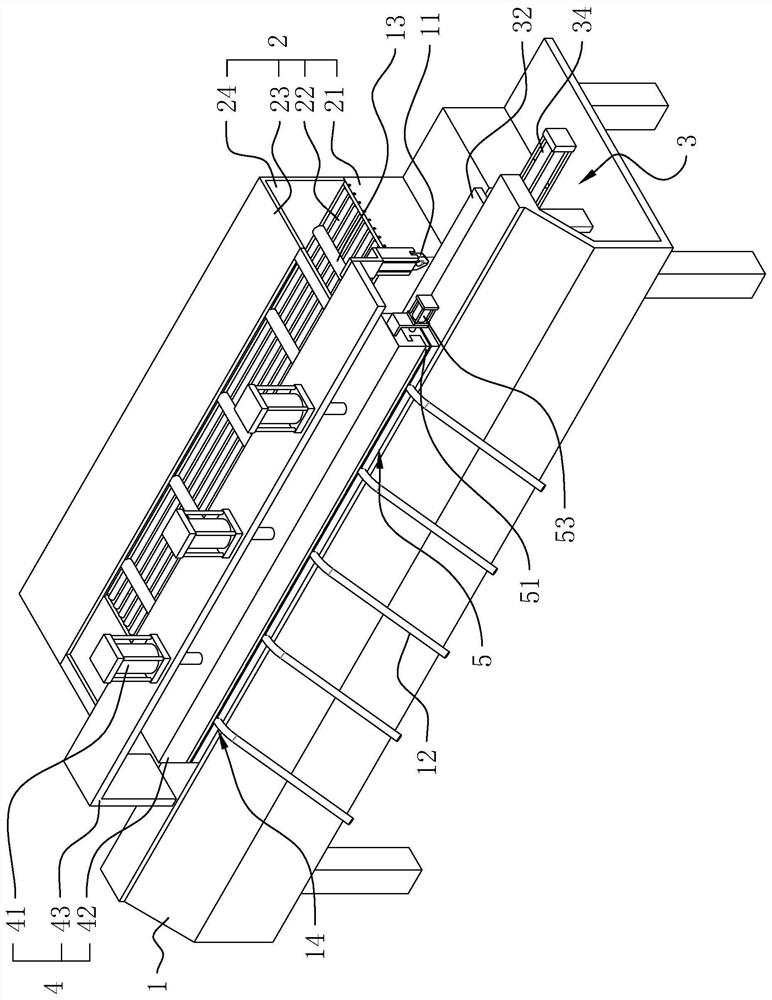

[0035] refer to figure 1 and figure 2 , is a heat-shrinkable tube heating device disclosed in the present invention, comprising a support frame 1, and the two ends of the support frame 1 are respectively set as a feed end and a discharge end. One side of the feeding end is provided with a vertically downward feeding mechanical claw 11 , the wire harness 12 is clamped under the feeding mechanical claw 11 , and one end of the wire harness 12 is wrapped with a heat-shrinkable tube 13 . The discharge end is provided with the same discharge mechanical claw (not shown in the figure) as the feed mechanical claw 11, and the discharge mechanical claw can move toward the next process.

[0036]One side of the support frame 1 between the feed end and the discharge end is provided with a heating assembly 2 for heating the heat shrinkable tube 13 wrapping the wire harne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com