Ultrasonic rolling extrusion 42CrMo bearing ring surface layer performance optimization method based on Taguchi algorithm

A bearing ring, Taguchi algorithm technology, applied in neural learning methods, design optimization/simulation, geometric CAD, etc., can solve the problems of easy fatigue on the surface of the ring, affecting the service life of the bearing, etc., to achieve a good surface condition, improve accuracy accuracy, improved accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

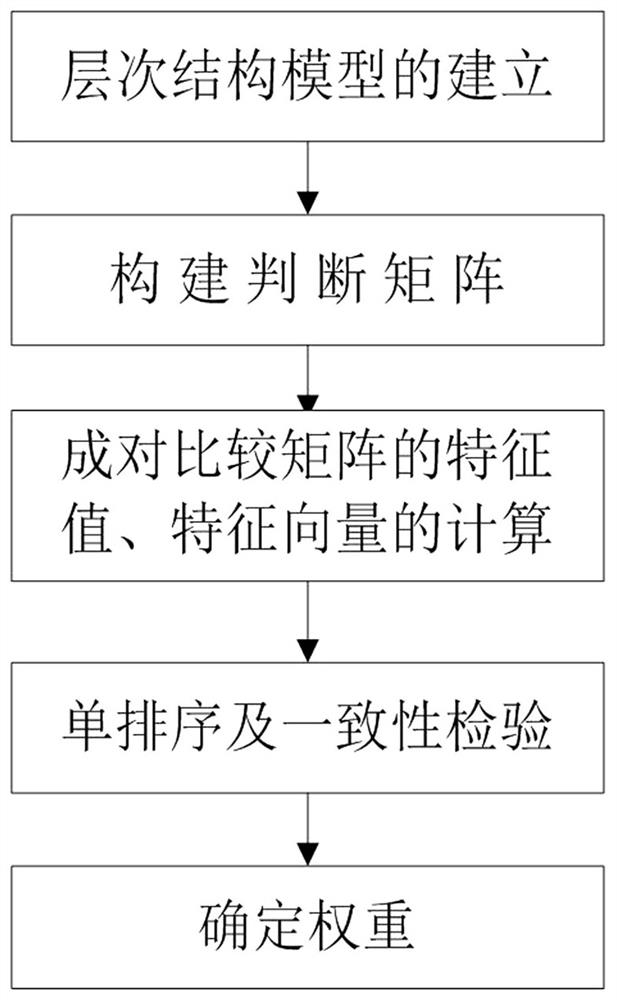

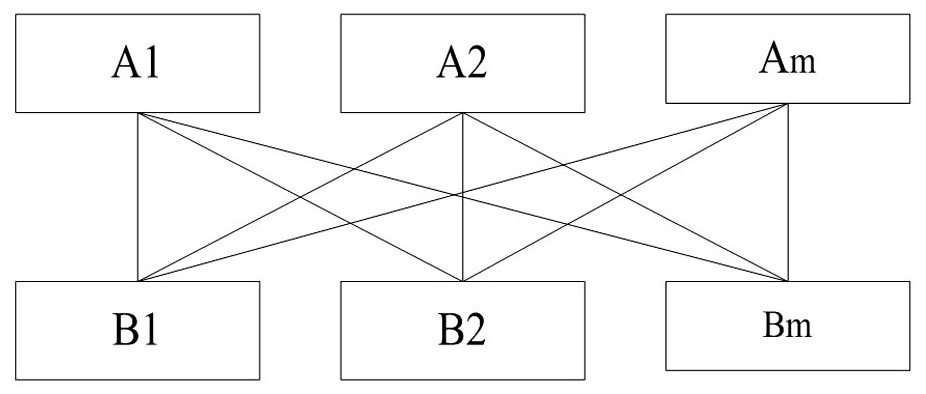

[0059] The present invention proposes a method for optimizing the performance of the surface layer of a 42CrMo bearing ring by ultrasonic rolling based on the Taguchi algorithm, comprising the following steps:

[0060] S1. According to the process parameters of ultrasonic rolling extrusion of 42CrMo bearing rings and the performance parameters of the surface layer of 42CrMo bearing rings, an orthogonal test is carried out.

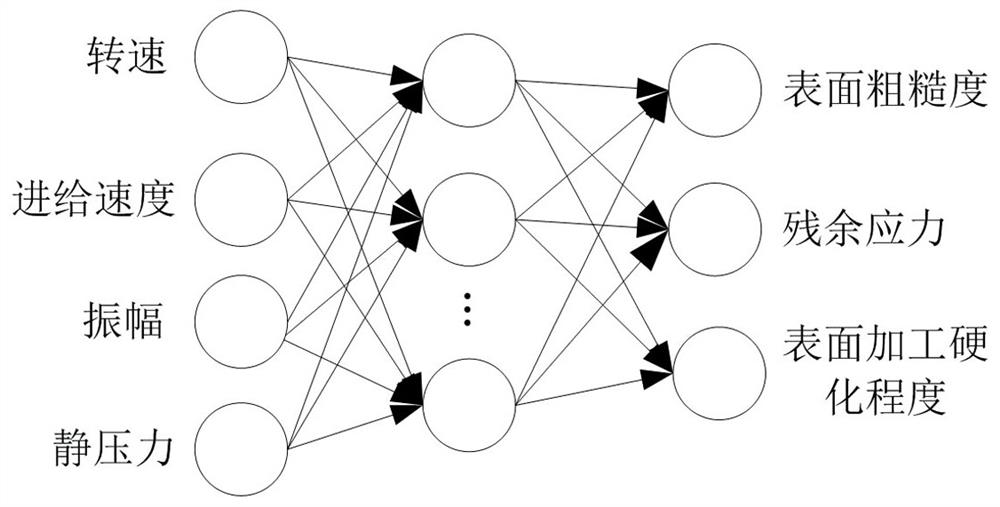

[0061] In this embodiment, the process parameters of ultrasonic rolling extrusion of 42CrMo bearing rings are rotational speed, feed speed, amplitude and static pressure, and the performance characterization parameters of the surface layer of 42CrMo bearing rings are surface roughness, residual stress and surface work hardening degree; based on This is an orthogonal experiment with four factors and five levels.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com