Preparation method and application of durable hydrophilic polypropylene foamed particles

A technology of foamed particles and polypropylene, applied in chemical instruments and methods, granular microbial carrier treatment, biological water/sewage treatment, etc., can solve the problems of difficult development of polypropylene foam, and achieve industrial scale production and application , The production process is simple and the effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a kind of preparation method of polypropylene expanded particle, comprises the following steps:

[0044] 1) After mixing polypropylene, high-density polyethylene-octene copolymerized elastomer, hydrophilic auxiliary agent and antioxidant, a compound is obtained;

[0045] 2) Blending and extruding the mixture obtained in the above steps with the supercritical fluid, and cutting into pellets to obtain expanded polypropylene particles.

[0046] The invention firstly mixes the polypropylene, the high-density polyethylene-octene copolymerized elastomer, the hydrophilic auxiliary agent and the antioxidant to obtain the mixture.

[0047] In the present invention, the added amount of the polypropylene is preferably 50-80 parts by weight, more preferably 55-75 parts by weight, more preferably 60-70 parts by weight.

[0048] In the present invention, the melt index of the polypropylene is preferably 0.5-10 g / 10 min, more preferably 2.5-8 g / 10 min, more prefe...

Embodiment 1

[0096] Dry polypropylene RS1684 and antioxidant in a vacuum oven at 60-80 degrees Celsius for 3-6 hours, and then mix polypropylene and high-density polyethylene-octene copolymer elastomer in a mixer for 10- 15 minutes.

[0097] Extrude and foam the mixed material through a twin-screw extruder, add 3% hydrophilic additive and 1% antioxidant, control the overall temperature of the screw at 190°C-220°C, and the temperature of the extrusion die is 220°C-240°C, add a small amount of carbon dioxide foaming agent through a booster pump, the dosage is 0.001L / min-0.002L / min, and the die pressure is 2-4MPa, and the foam strip can be produced.

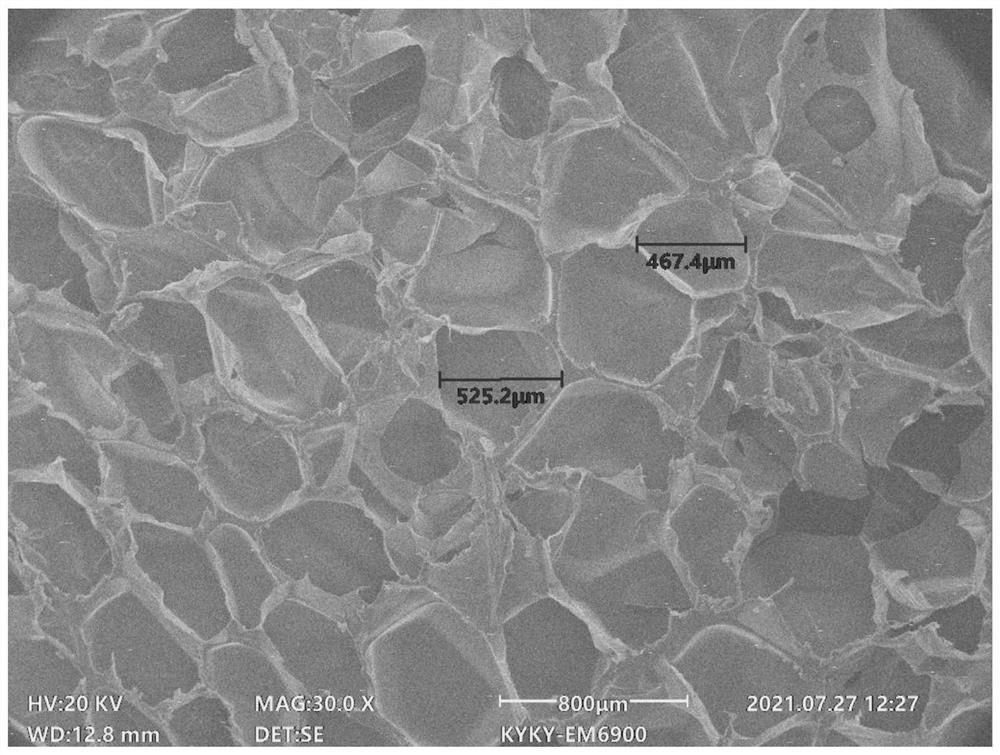

[0098] The foam strips are cut at a constant speed by a granulator to produce hexagonal porous foam particles with a diameter of 1.0-2.5 cm. The diameter of the macropore is 450-530μm, and the expansion ratio is 3 times.

[0099] The polypropylene foamed particles prepared in Example 1 of the present invention were characterized.

[0100] see...

Embodiment 2

[0103] Dry the polypropylene RS1684 and the antioxidant in a vacuum oven at 60-80 degrees Celsius for 3-6 hours, and then mix the polypropylene and high-density polyethylene-octene copolymer elastomer in a mixer in a ratio of 60:40 for 10- 15 minutes.

[0104] Through a twin-screw extruder, the mixed material is extruded and foamed, and 4% of hydrophilic additives and 1.5% of antioxidant are added. The overall temperature of the screw is controlled at 190°C-220°C, and the extrusion die temperature is 220°C-240°C, add a small amount of carbon dioxide foaming agent through a booster pump, the dosage is 0.001L / min-0.002L / min, and the die pressure is 2-4MPa, and the foam strip can be produced.

[0105] Cut the foam strips at a constant speed by a granulator to produce hexagonal porous foam particles with a diameter of 1.0-2.5 cm, the diameter of the macropores is 300-500 μm, and the expansion ratio is 2 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com