3D printing hydrogel for treating or preventing intrauterine adhesion and preparation method of hydrogel

A 3D printing, intrauterine adhesion technology, applied in medical science, surgery, additive processing, etc., can solve the problem of reduced cell proliferation rate and cell viability, single structure of pure collagen hydrogel, poor mechanical properties and rapid degradation and other problems, to achieve the effects of controllable degradability, high cell encapsulation efficiency, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

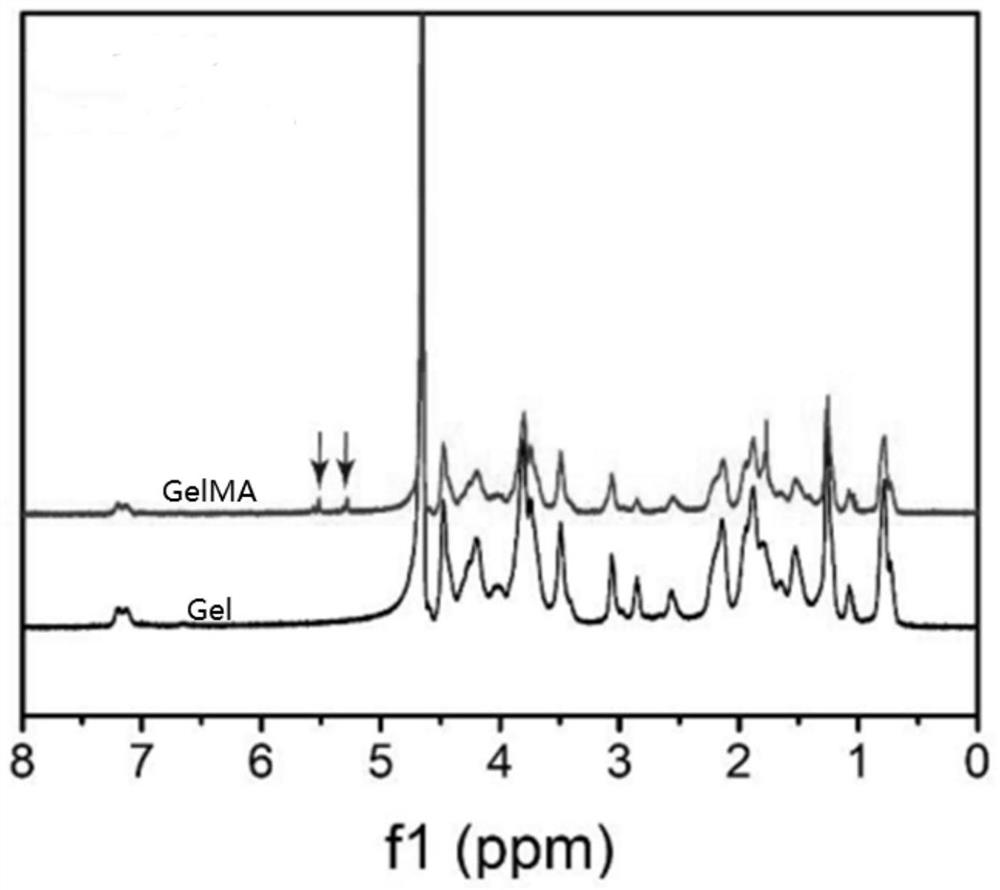

[0033] Preparation of methacrylated gelatin (GelMA): 10 g of gelatin was dissolved in 100 mL of deionized water at 50° C. to prepare a gelatin solution. Then 6 mL of methacrylic anhydride was added dropwise to the gelatin solution, and the reaction was stirred for 6 h. Dialyze with distilled water for 3-5 days in a dialysis bag (molecular weight cut-off: 12-14 kDa) to remove impurities and unreacted methacrylic anhydride. Finally, it was freeze-dried and stored in the dark at -80°C until use.

Embodiment 2

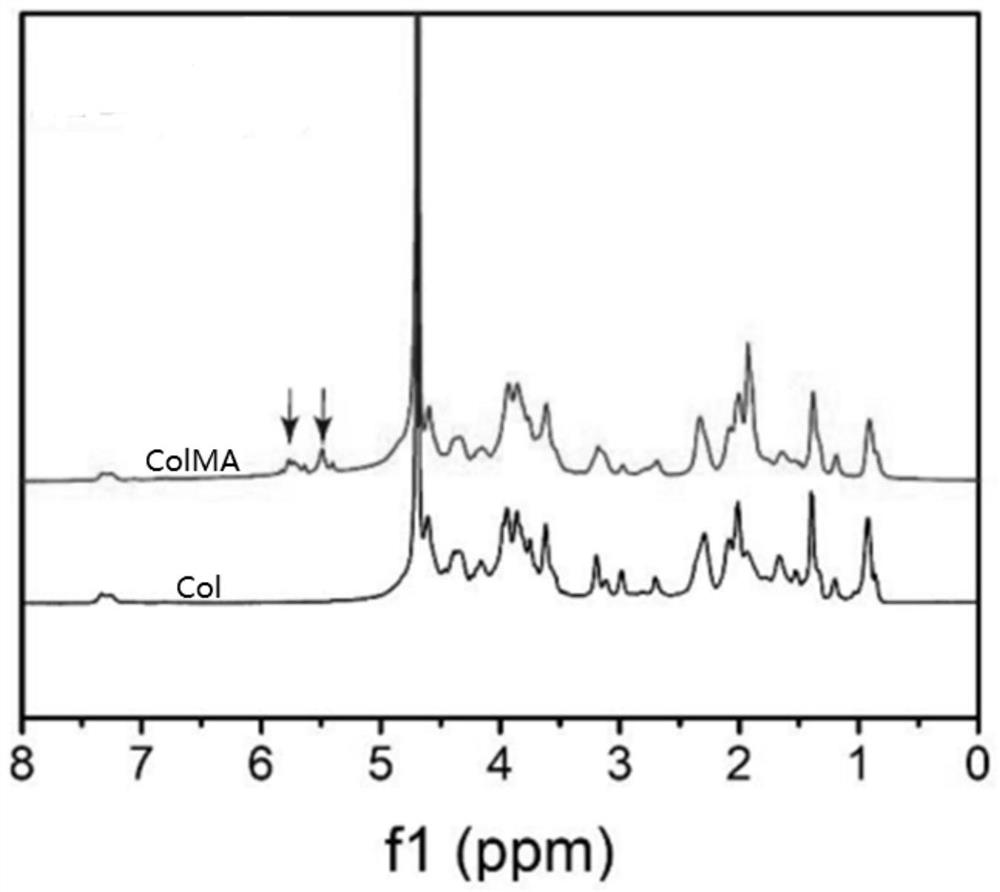

[0035] Preparation of methacrylated collagen (ColMA): 2 g of collagen was dissolved in 100 mL of deionized water at 37° C. to prepare a collagen solution. Then, 1.2 mL of methacrylic anhydride was added dropwise to the collagen solution, stirred for 12 hours, and the pH value of the reaction system was kept at 8-9 by using NaOH with a concentration of 5 mol / L. Dialyze with distilled water in a dialysis bag (molecular weight cut-off: 12-14kDa) for 3-5 days, then freeze-dry the final dialysis product, and store it in the dark at -20°C until use.

Embodiment 3

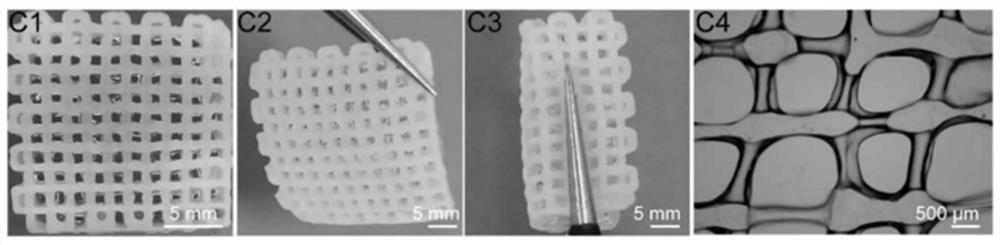

[0037] A preparation method for 3D printing hydrogel, the steps are as follows:

[0038] (1) Preparation of printing ink: the methacrylated gelatin prepared in Example 1, the methacrylated collagen prepared in Example 2, and the LAP photoinitiator were added to deionized water, and mixed evenly to obtain a printing ink, which was stored until Wherein, by the volume of deionized water, the addition amount of methacrylated gelatin is 5% g / mL, the addition amount of methacrylated collagen is 0.5% g / mL, the addition amount of LAP photoinitiator 0.01% g / mL;

[0039] (2) Design and load the 3D model: use 3DS Max software to design the model, import the model into the 3D printer control software, the model is a layer-by-layer lattice structure, and the specification is 16mm×16mm×2 layers;

[0040] (3) 3D printing preparation: transfer the printing ink prepared in step (1) to the extrusion cylinder of the extruded bio-3D printer, set the fiber diameter to 100 μm, the printing speed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com