Silver phosphate-hydroxyapatite-graphite phase carbon nitride composite photocatalyst as well as preparation method and application thereof

A technology of graphite phase carbon nitride and hydroxyapatite, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of unstable photosensitivity, achieve broad application prospects, convenient operation, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to a first aspect of the present invention, a method for preparing a silver phosphate-hydroxyapatite-graphite phase carbon nitride composite photocatalyst is provided, comprising the following steps:

[0036] (a) Mix oyster shell powder and acid solution to react and separate to obtain mixed solution A;

[0037] The pH value of the mixed solution B formed by the mixed solution A and the phosphate-containing solution is adjusted to alkaline, and then mixed with graphite-phase carbon nitride to perform a hydrothermal reaction, and the hydrothermal reaction product is separated and dried to obtain hydroxyapatite -Graphite phase carbon nitride composite carrier; wherein, the mass ratio of oyster shell powder to graphite phase carbon nitride is (3-4):1;

[0038] (b) mixing the hydroxyapatite-graphite phase carbon nitride composite carrier with water to obtain a carrier turbid liquid;

[0039] The silver nitrate solution and the carrier turbid solution are mixed, t...

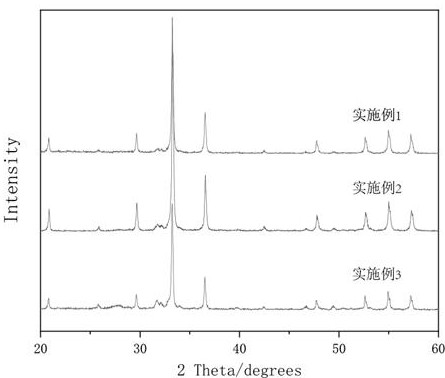

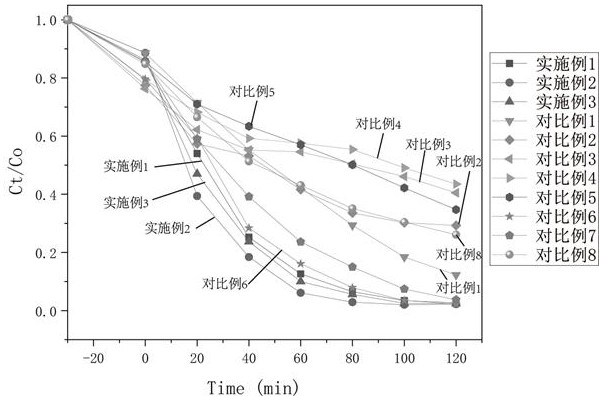

Embodiment 1

[0068] This embodiment provides a method for preparing a silver phosphate-hydroxyapatite-graphite phase carbon nitride composite photocatalyst, comprising the following steps:

[0069] (a) Preparation of hydroxyapatite-graphite carbon nitride composite support

[0070] The preparation method of oyster shell powder: the oyster shell is washed and dried, and then ground into powder, and the average particle diameter of the oyster shell powder is 200 mesh.

[0071] The preparation method of graphite phase carbon nitride: take urea solid, grind it into powder, transfer it to a crucible, put it in a muffle furnace, and react at 550°C for 8 hours to obtain a porous light yellow solid, and grind it to obtain graphite phase carbon nitride powder end.

[0072] Mix 0.25 g of graphitic carbon nitride with 50 mL of water, and process it ultrasonically to obtain a carbon nitride solution.

[0073] Mix the above 1.0g oyster shell powder with 40mL acetic acid solution (volume fraction 10%)...

Embodiment 2

[0078] This example provides a method for preparing silver phosphate-hydroxyapatite-graphite-phase carbon nitride composite photocatalyst, except that the amount of graphite-phase carbon nitride in step (a) is replaced by 0.25g to 0.3g, and the remaining steps Same as Example 1.

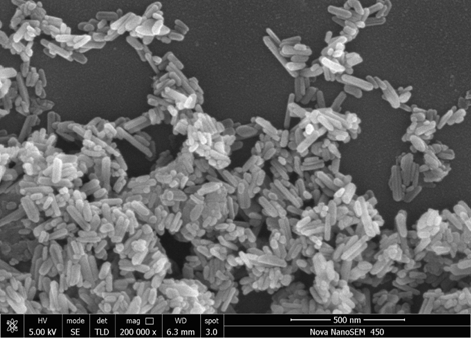

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com