A mesoporous alumina-based core-shell composite material and its single micelle-guided interface assembly method and application

A technology of mesoporous alumina and composite materials, applied in chemical instruments and methods, alumina/aluminum hydroxide, nanotechnology for materials and surface science, etc. The thickness of the alumina shell is not uniform, and there is no mesoporous structure, etc., to achieve the effect of large pore size, large pore volume, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Mix 1.5g F127 (surfactant), 75mL tetrahydrofuran and 12mL concentrated hydrochloric acid (36-38wt%), stir at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then add 2.0g aluminum isopropoxide and continue stirring for one hour ; Transfer the mixed solution to a constant temperature drying box and place it at 40°C for 48h to obtain a white single micellar gel;

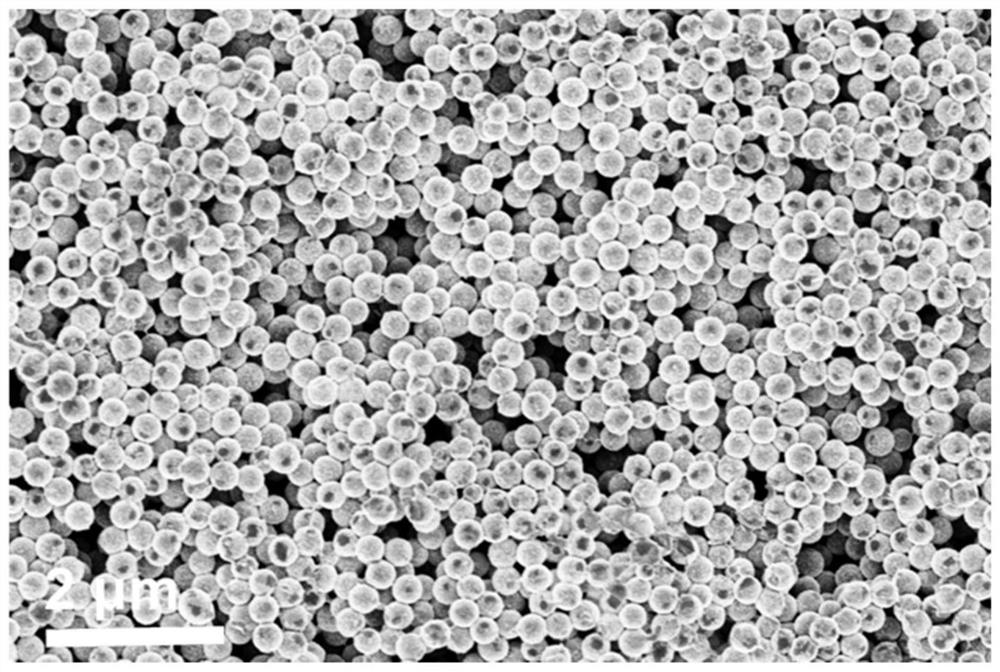

[0047] 1.0g of monomicellar gel and 100mg of phenolic resin spheres were dispersed in a mixed solution of 30mL of ethanol and 100mL of water, then transferred to a hydrothermal kettle for 24h at 160°C; the obtained product was washed with absolute ethanol, and then The phenolic resin microspheres@mesoporous alumina composite was obtained by calcining at 700 °C for 3 h under nitrogen protection atmosphere to remove the surfactant.

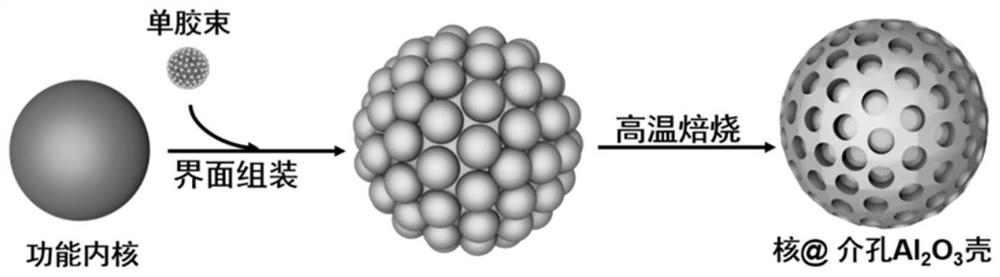

[0048] See figure 1 , in this example, the surfactant Pluronic F127 (EO 106 -PO 70 -EO 106 ) as the template agent, aluminum isopropoxide as the a...

Embodiment 2

[0054] Mix 1.5g F127, 75mL tetrahydrofuran and 12mL concentrated hydrochloric acid (36-38wt%), stir at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then add 2.0g aluminum isopropoxide, continue stirring for one hour; transfer the mixed solution In a constant temperature drying box, placed at 40°C for 48h to obtain a white single micelle gel;

[0055] 1.0g of single micelle gel and 100mg of graphene were dispersed in a mixed solution of 30mL of ethanol and 100mL of water, then transferred to a hydrothermal kettle for 24h at 160 °C; the obtained product was washed with absolute ethanol, and then placed in a After calcination at 700 °C for 3 h to remove the surfactant, graphene@mesoporous alumina composites were obtained.

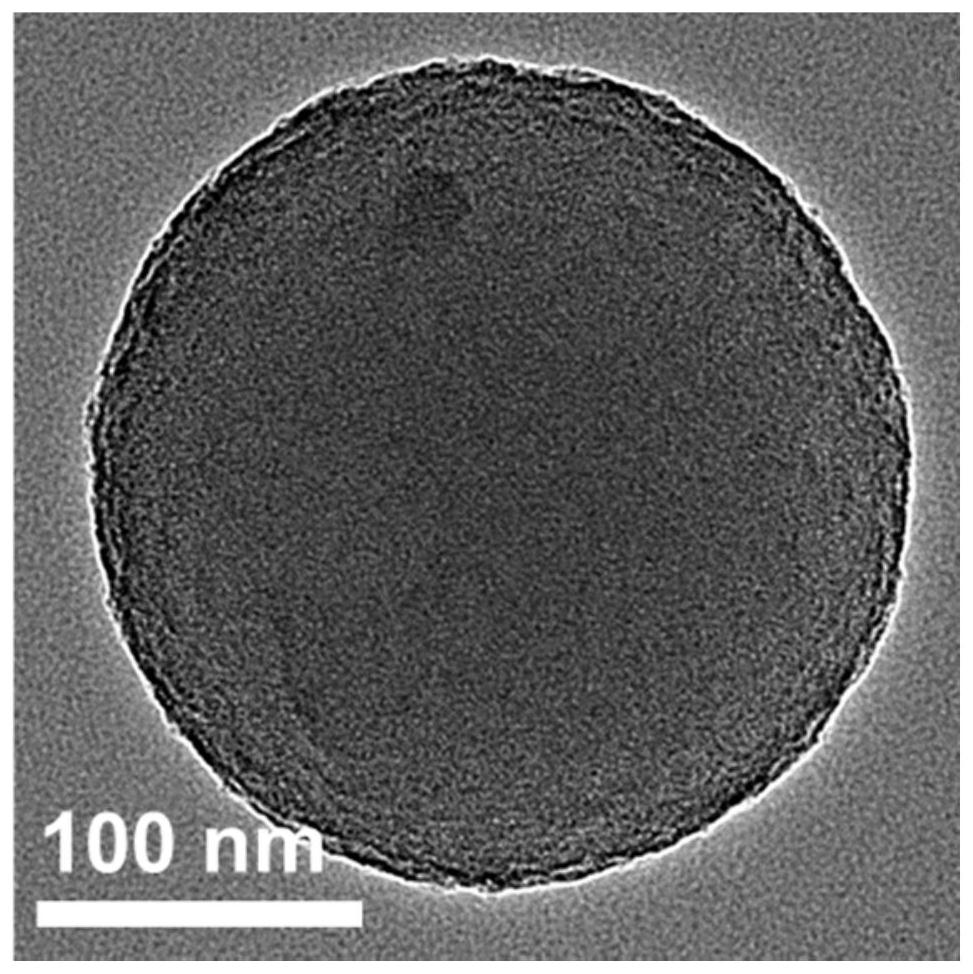

[0056] See Figure 7-8 , Figure 7 SEM images and Figure 8 Transmission electron microscopy images showed that the mesoporous alumina shell was uniformly and densely wrapped on graphene, with a pore size of ~5 nm.

Embodiment 3

[0058] Mix 1.5g F127, 75mL tetrahydrofuran and 12mL concentrated hydrochloric acid (36-38wt%), stir at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then add 2.0g aluminum isopropoxide, continue stirring for one hour; transfer the mixed solution In a constant temperature drying box, placed at 40°C for 48h to obtain a white single micelle gel;

[0059] 1.0g of monomicellar gel and 100mg of phenolic resin spheres were dispersed in a mixed solution of 30mL of ethanol and 100mL of water, then transferred to a hydrothermal kettle for 24h at 160°C; the obtained product was washed with absolute ethanol, and then The surfactant was removed by calcining at 700℃ for 3h in air atmosphere, and hollow mesoporous alumina nanospheres were obtained.

[0060] See Figure 9 , Figure 9 TEM images showed that the hollow mesoporous alumina nanospheres were uniform in size, with a shell thickness of about ∼10 nm and a pore size of ∼5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com