A kind of cobalt nitrogen co-doped fish scale biochar catalyst and its preparation method and application

A biochar and catalyst technology is applied in the field of cobalt-nitrogen co-doped fish scale biochar catalyst and preparation thereof, and the catalytic hydrogenation of levulinic acid to prepare γ-valerolactone, which can solve the problems of difficult industrialized production, corrosion of reaction equipment, and process problems. Complexity and other problems, to achieve the effects of enhanced dispersion, large mitigation, and high catalytic conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

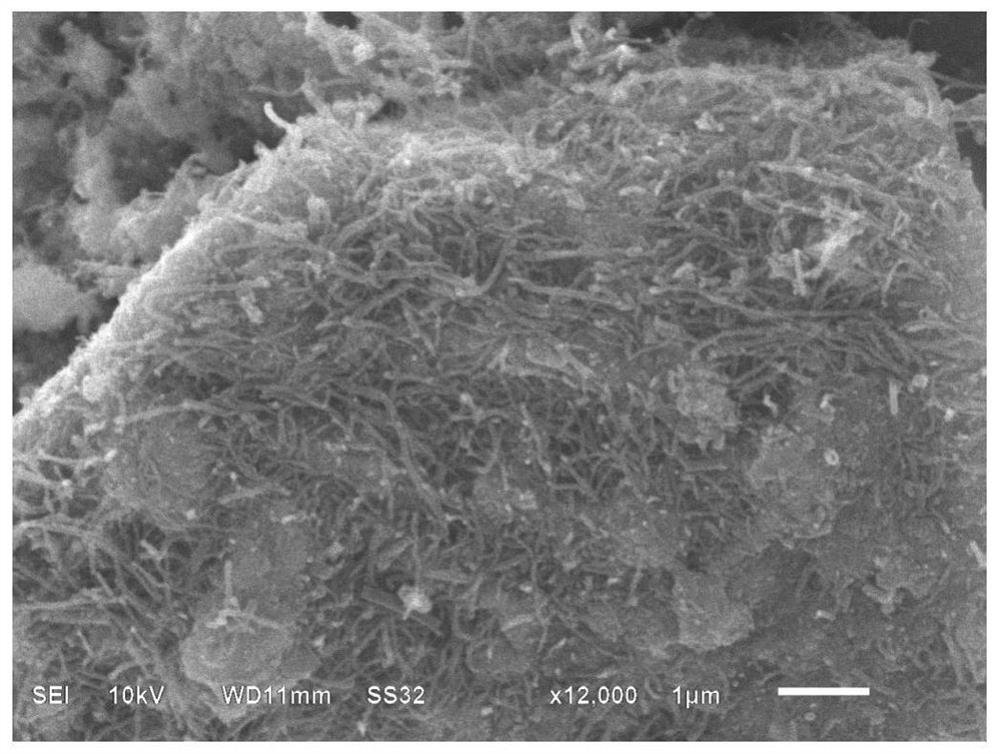

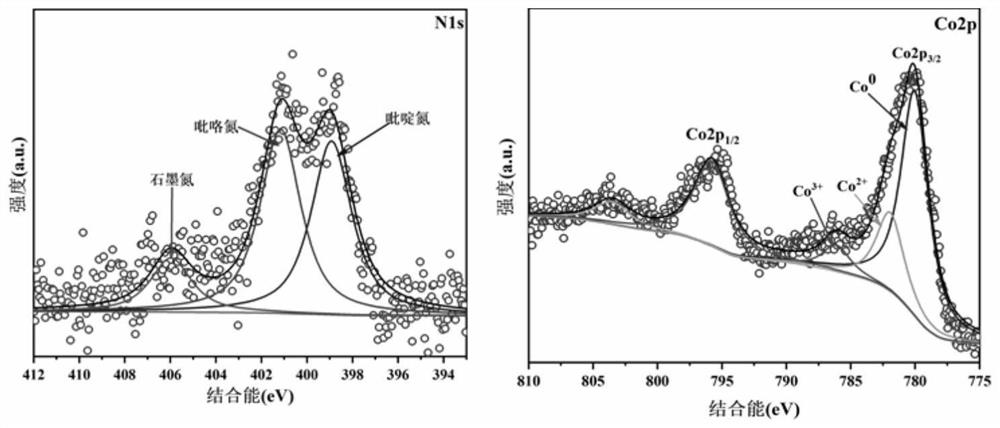

[0027] After the fish scales are washed, dry them at 80°C and grind them into powder, weigh 10g of fish scale powder and 60mL of water for ultrasonic treatment, put them in a polytetrafluoroethylene reactor for hydrothermal carbonization at 200°C for 12 hours, and dry them to obtain fish scale biochar; weigh 4g Dissolve cobalt nitrate in 40mL of ethanol, slowly add ethylenediamine dropwise during stirring until the solution becomes a paste, dry the paste at 80°C to obtain brown-yellow ethylenediamine cobalt; weigh 1g fish scale biochar, 2g melamine and 1.2337g ethylenediamine cobalt were ground in an agate mortar evenly, and then the mixture was heated at 700°C and N 2 Pyrolysis under atmosphere for 2h (heating rate 4°C / min), take out after natural cooling to obtain cobalt nitrogen co-doped carbon catalyst. The specific surface area of the catalyst determined by nitrogen adsorption is 430m 2 / g, the elemental analysis determined that the nitrogen doping amount in the cataly...

Embodiment 2

[0030] After the fish scales are washed, dry them at 80°C and grind them into powder, weigh 10g of fish scale powder and 60mL of water for ultrasonic treatment, put them in a polytetrafluoroethylene reactor for hydrothermal carbonization at 200°C for 12 hours, and dry them to obtain fish scale biochar; weigh 4g Dissolve cobalt nitrate in 40mL of ethanol, slowly add ethylenediamine dropwise during stirring until the solution becomes a paste, dry the paste at 80°C to obtain brown-yellow ethylenediamine cobalt; weigh 1g fish scale biochar, 2g melamine and 1.2337g of ethylenediamine cobalt were ground in an agate mortar evenly, and then the mixture was heated at 800°C and N 2 Pyrolysis under atmosphere for 2h (heating rate 4°C / min), take out after natural cooling to obtain cobalt nitrogen co-doped carbon catalyst. The specific surface area of the catalyst determined by nitrogen adsorption is 380m 2 / g, elemental analysis determined that the nitrogen doping amount in the catalys...

Embodiment 3

[0033] After the fish scales are washed, dry them at 80°C and grind them into powder, weigh 10g of fish scale powder and 60mL of water for ultrasonic treatment, put them in a polytetrafluoroethylene reactor for hydrothermal carbonization at 200°C for 12 hours, and dry them to obtain fish scale biochar; weigh 4g Dissolve cobalt nitrate in 40mL of ethanol, slowly add ethylenediamine dropwise during stirring until the solution becomes a paste, dry the paste at 80°C to obtain brown-yellow ethylenediamine cobalt; weigh 1g fish scale biochar, 2g melamine and 1.2337g ethylenediamine cobalt were ground in an agate mortar evenly, and then the mixture was heated at 700°C and N 2 Pyrolysis under atmosphere for 2h (heating rate 4°C / min), take out after natural cooling to obtain cobalt nitrogen co-doped carbon catalyst. The specific surface area of the catalyst determined by nitrogen adsorption is 430m 2 / g, the elemental analysis determined that the nitrogen doping amount in the cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com