Polymer surface decoration wear-resistant coating and preparation method thereof

A wear-resistant coating and surface decoration technology, applied in the field of decorative wear-resistant coatings on polymer surfaces and their preparation, can solve problems such as large differences in thermal expansion coefficients, large differences in mechanical properties, and difficult fire control, and achieve excellent bearing capacity. Ability, mechanical properties matching, the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

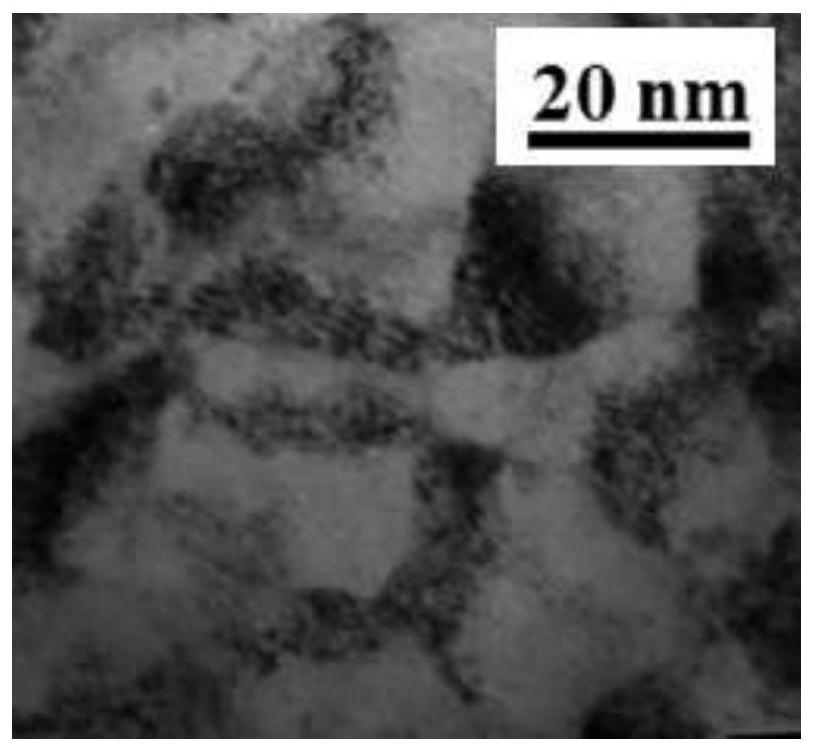

Image

Examples

Embodiment 1

[0038] In the present embodiment, the PC substrate surface is processed as follows sequentially:

[0039] (1) Place the base material in a vacuum cavity, pass argon gas into the cavity, and use the anode layer ion source to pre-treat the base material;

[0040](2) Introduce argon gas and nitrogen gas into the chamber with a flow ratio of 5:1, and open the chromium target and copper target for co-deposition at the same time. The copper target and the chromium target are connected to the center of the chamber respectively, and The angle between them is 40 degrees, the substrate is located on the line connecting the chromium target and the center of the cavity, and the distance from the target is 13 cm. The chromium target adopts a high-power pulse power supply, the copper target adopts a DC power supply, the sputtering power of the chromium target is 2500W, the sputtering power of the copper target is 300W, and the background vacuum degree of the vacuum chamber is 2×10 -5 Torr,...

Embodiment 2

[0043] In the present embodiment, the surface of the ABS substrate is sequentially processed as follows:

[0044] (1) Place the base material in a vacuum cavity, pass argon gas into the cavity, and use the anode layer ion source to pre-treat the base material;

[0045] (2) Introduce argon gas and nitrogen gas into the chamber with a flow ratio of 5:1, and open the chromium target and copper target for co-deposition at the same time. The copper target and the chromium target are connected to the center of the chamber respectively, and The angle between them is 40 degrees, the substrate is located on the line connecting the chromium target and the center of the cavity, and the distance from the target is 13 cm. The chromium target adopts a high-power pulse power supply, the copper target adopts a DC power supply, the sputtering power of the chromium target is 3000W, the sputtering power of the copper target is 400W, and the background vacuum degree of the vacuum chamber is 3×10 ...

Embodiment 3

[0048] In the present embodiment, the surface of the PEEK substrate is sequentially processed as follows:

[0049] (1) Place the base material in a vacuum cavity, pass argon gas into the cavity, and use the anode layer ion source to pre-treat the base material;

[0050] (2) Introduce argon and nitrogen into the cavity with a flow ratio of 10:1, and simultaneously open the chromium target and the copper target for co-deposition. The copper target and the chromium target are respectively connected to the center of the cavity, and The angle between them is 60 degrees, the substrate is located on the line connecting the chromium target and the center of the cavity, and the distance from the target is 15 cm. The chromium target adopts a high-power pulse power supply, the copper target adopts a DC power supply, the sputtering power of the chromium target is 3500W, the sputtering power of the copper target is 500W, and the background vacuum degree of the vacuum chamber is 4×10 -5 To...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com