In-vivo absorbable metal anastomosis nail and preparation method thereof

A staple and metal technology, which is applied in the field of absorbable metal staples in vivo and their preparation, can solve the problems of reducing the biocompatibility and safety of the device, inflammatory reaction of surrounding tissues, and slowly releasing debris, etc., so as to avoid premature Ineffectiveness, good biocompatibility, reduced degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

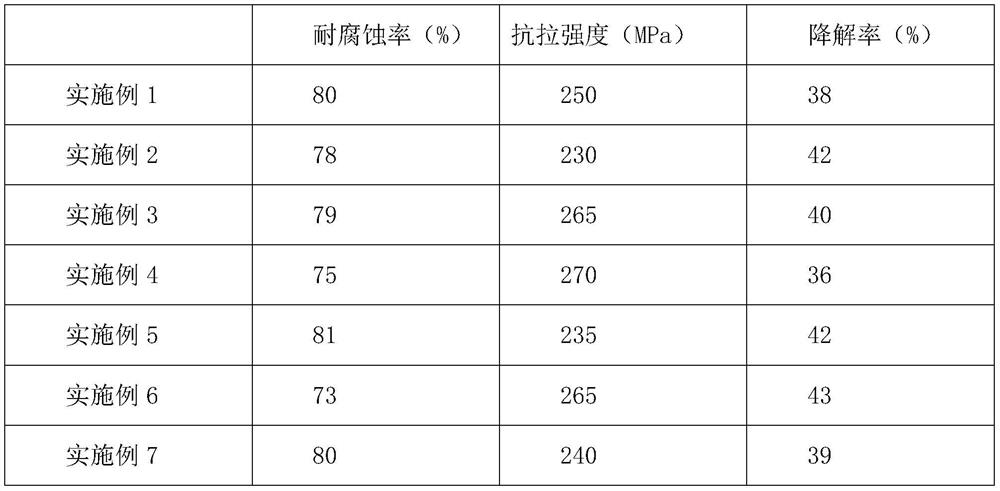

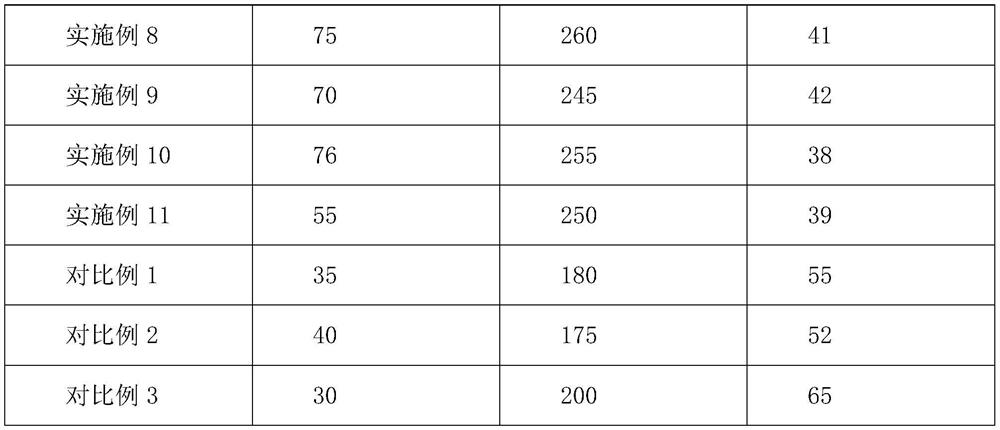

Examples

Embodiment 1

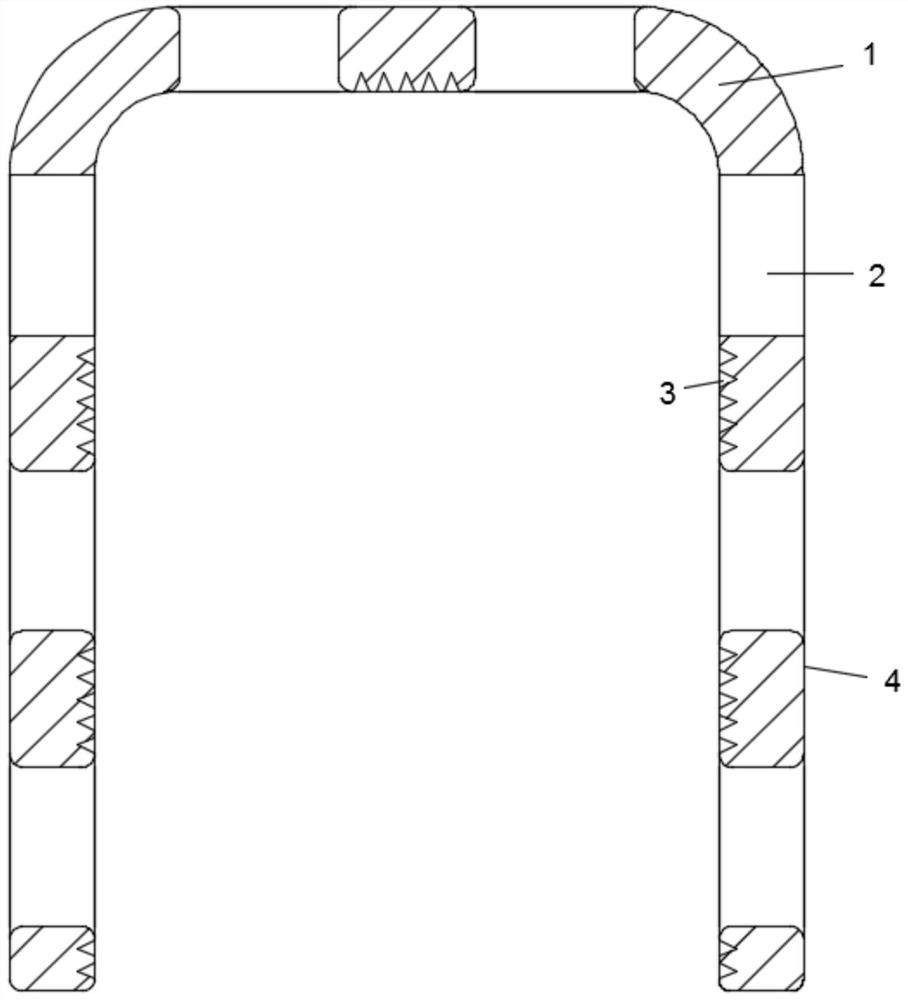

[0034] combine figure 1 As shown, an in vivo absorbable metal stapler includes a U-shaped body 1; the U-shaped body 1 is provided with a plurality of evenly arranged through grooves 2, and the inner wall of the U-shaped body 1 is provided with a plurality of locking grooves 3 , the locking slot 3 and the through slot 2 are staggered;

[0035] The surface of the U-shaped body 1 is provided with a coating 4 with corrosion resistance and excellent biocompatibility;

[0036] The staple is made of a U-shaped body 1 made of magnesium alloy and a coating 4 made of zinc alloy; the U-shaped body 1 is composed of the following raw materials by weight: 3.5% Zn, 0.415% Ca , 0.35Fe, 3.15%Mn, 0.1% rare earth, the balance is Mg;

[0037] The plating layer 4 is composed of the following raw materials in parts by weight: 0.0955% Mg, 0.75045% Ca, 1.0043% Cu, and the rest is Zn.

[0038] In this embodiment, the preparation method of the in vivo absorbable metal staples, the steps are as follo...

Embodiment 2

[0046] combine figure 1 As shown, an in vivo absorbable metal stapler includes a U-shaped body 1; the U-shaped body 1 is provided with a plurality of evenly arranged through grooves 2, and the inner wall of the U-shaped body 1 is provided with a plurality of locking grooves 3 , the locking slot 3 and the through slot 2 are staggered;

[0047]The surface of the U-shaped body 1 is provided with a coating 4 with corrosion resistance and excellent biocompatibility;

[0048] The staple is made of a U-shaped body 1 made of magnesium alloy and a coating 4 made of zinc alloy; the U-shaped body 1 is composed of the following raw materials by weight: 1.8% Zn, 0.18% Ca , 0.25% Fe, 3.6% Mn, 0.15% rare earth, and the balance is Mg;

[0049] The plating layer 4 is composed of the following raw materials by weight: 0.001% Mg, 0.0009% Ca, 2% Cu, and the rest is Zn.

[0050] In this embodiment, the preparation method of the in vivo absorbable metal staples, the steps are as follows:

[005...

Embodiment 3

[0058] combine figure 1 As shown, an in vivo absorbable metal stapler includes a U-shaped body 1; the U-shaped body 1 is provided with a plurality of evenly arranged through grooves 2, and the inner wall of the U-shaped body 1 is provided with a plurality of locking grooves 3 , the locking slot 3 and the through slot 2 are staggered;

[0059] The surface of the U-shaped body 1 is provided with a coating 4 with corrosion resistance and excellent biocompatibility;

[0060] The staple is made of a U-shaped body 1 made of magnesium alloy and a coating 4 made of zinc alloy; the U-shaped body 1 is composed of the following raw materials by weight: 5.2% Zn, 0.65% Ca , ~0.42% Fe, 2.7% Mn, 0.05% rare earth, and the balance is Mg;

[0061] The plating layer 4 is composed of the following raw materials in parts by weight: 0.19% Mg, 1.5% Ca, 0.0085% Cu, and the rest is Zn.

[0062] In this embodiment, the preparation method of the in vivo absorbable metal staples, the steps are as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com