Flame-retardant polyolefin composite material as well as preparation method and application thereof

A composite material and polyolefin technology, applied in the field of composite materials, can solve the problems of unsatisfactory flame retardancy and mechanical properties, and achieve the effects of improving mechanical properties and high temperature stability, excellent performance, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] On the other hand, the embodiment of the present invention also provides the preparation method of the above flame-retardant polyolefin composite material. The preparation method of above flame-retardant polyolefin composite material comprises the following steps:

[0045] S01. Weigh the formula components: weigh each component according to the formula of the flame-retardant polyolefin composite material above;

[0046] S02. Plasticizing after mixing: the weighed components are mixed and then plasticized to obtain a flame-retardant polyolefin composite material.

[0047] Specifically, the formulation of the flame-retardant polyolefin composite material in the above step S01 and the preferred content and type of each component in the formulation are as described above, and will not be repeated here to save space.

[0048] In an embodiment, at least one of magnesium hydroxide, calcium carbonate, and glass frit is ideally three when being surface-modified by a coupling ag...

Embodiment 1-6

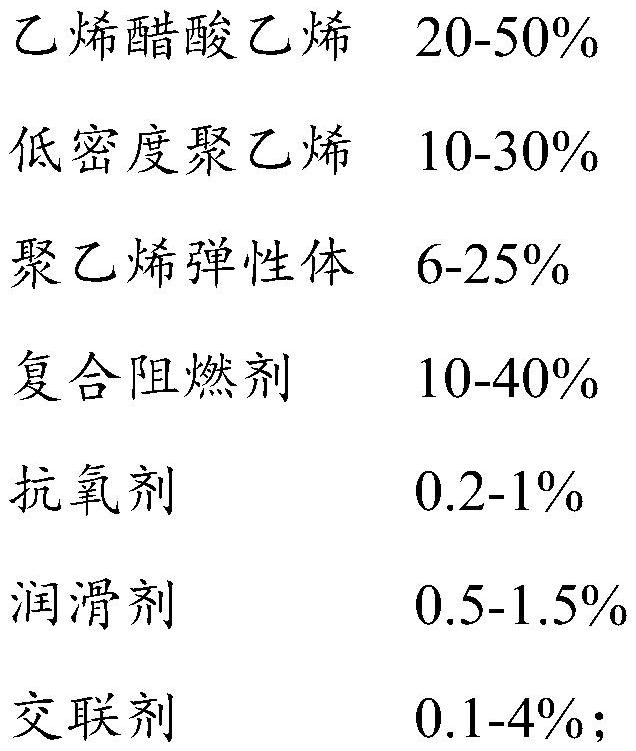

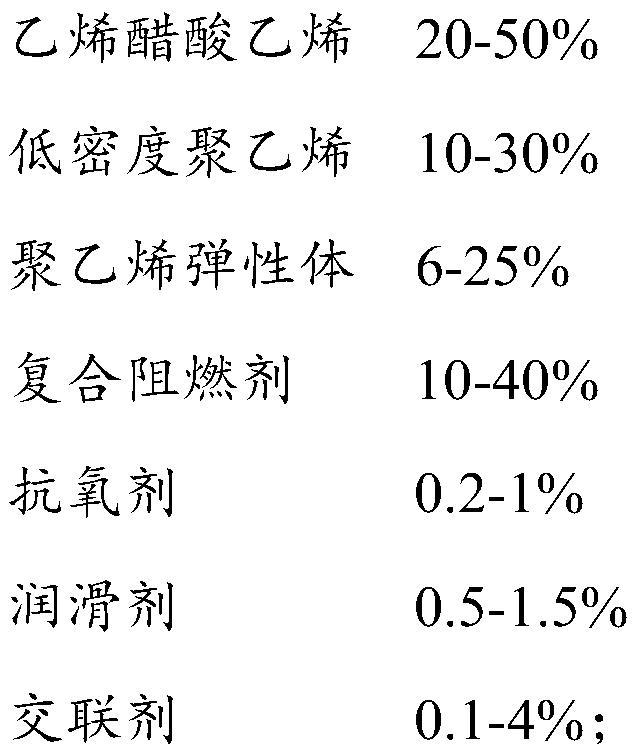

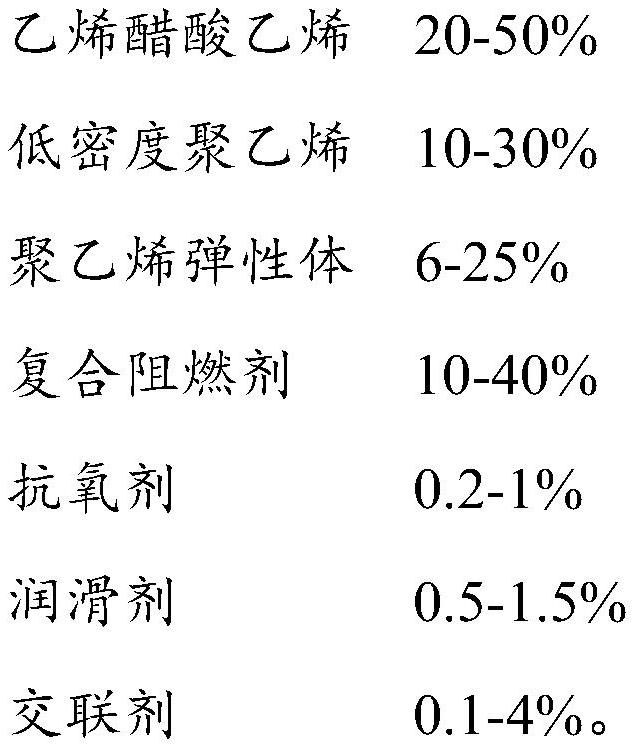

[0062] This embodiment 1-6 provides 6 kinds of flame-retardant polyolefin composite materials and their preparation methods. Among them, the six kinds of flame-retardant polyolefin composite materials respectively contain the components shown in Table 1. Their respective preparation methods are as described above in the preparation method of the flame-retardant polyolefin composite material.

[0063] Table 1

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com