Polyurethane elastomer preform and production method of polyurethane elastomer

A technology of polyurethane elastomer and production method, which is applied in the production field of polyurethane elastomer prefabricated products and polyurethane elastomer, and can solve the problems of low light transmittance and high hardness of polyurethane elastomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

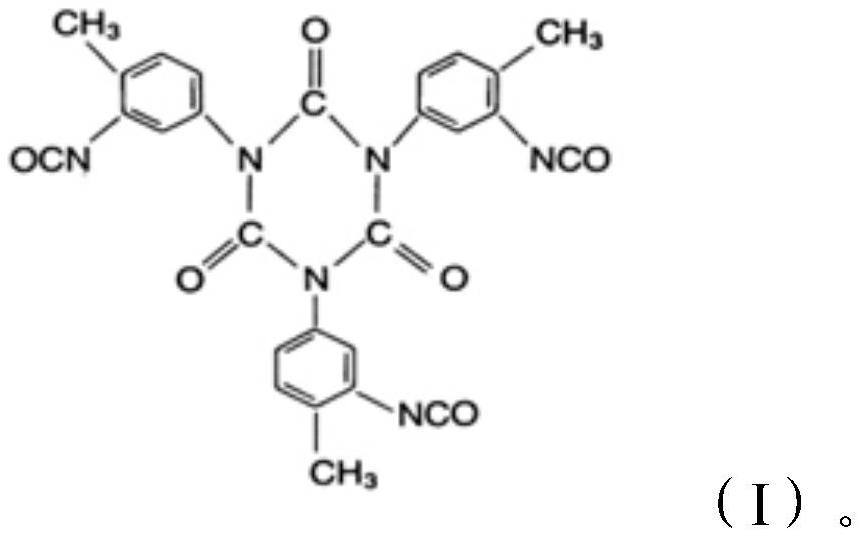

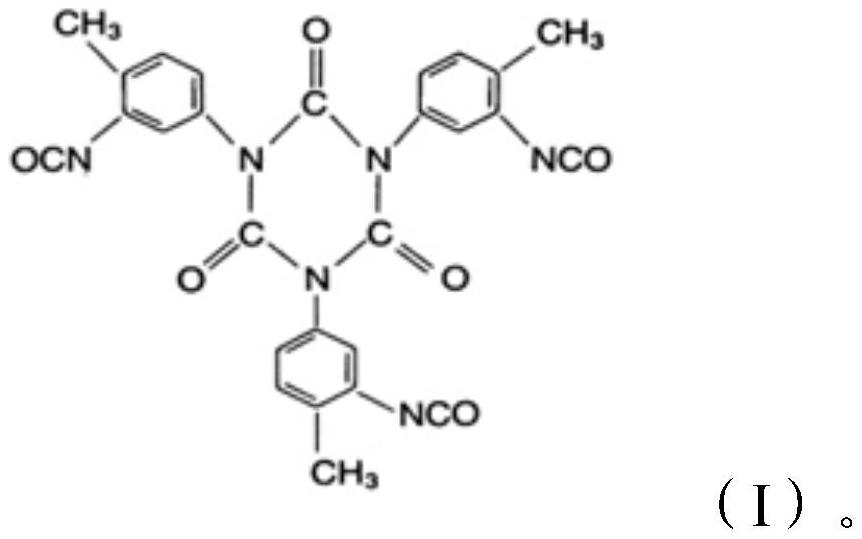

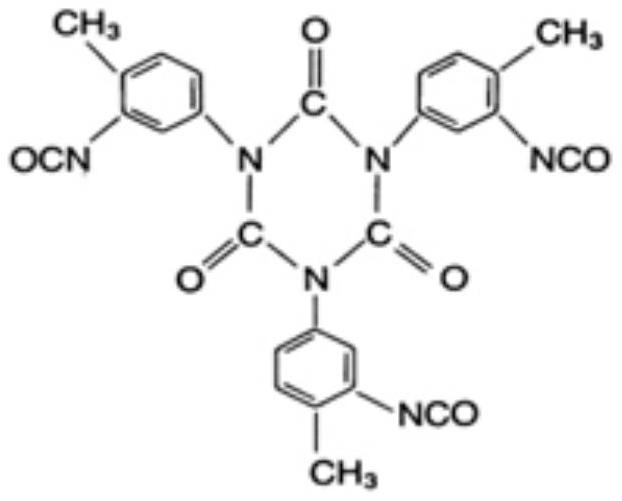

Image

Examples

Embodiment A1 and comparative example A1~A3

[0063] 100 parts by weight of the polymer polyol were vacuum dehydrated at 120° C. for 2 hours to obtain a dehydrated polymer polyol. Under the protection of nitrogen, mix the dehydrated polymer polyol, 11.27 parts by weight of BDO, 3.60 parts by weight of CHDM, 0.01 parts by weight of T12 and 0.2 parts by weight of IRGANOX 1010, and stir at 60°C and 800 rpm for 15 minutes to obtain a polymerization polyol component.

[0064] Under the protection of nitrogen, the temperature of HMDI was raised to 80° C., mixed with triazine compounds evenly, then mixed with 0.3 parts by weight of UV123, and stirred at 800 rpm for 15 minutes to obtain the isocyanate component.

[0065] At 60° C., the polymer polyol component and the isocyanate component were mixed, stirred at 1200 rpm for 3 minutes, and vacuum defoamed to obtain a polyurethane elastomer preform.

[0066] The details are shown in Table 1.

[0067] Table 1

[0068]

Embodiment B1 and comparative example B1~B4

[0074] The polyurethane elastomer preforms obtained in Example A1 and Comparative Examples A1-A4 were poured into a mold preheated to 110° C., and then placed in an oven at 110° C. for curing for 18 hours to obtain a polyurethane elastomer. The properties of the obtained polyurethane elastomer are shown in Table 2.

[0075] Table 2

[0076]

[0077] Note: Tear strength is tested by the method specified in GB / T528-2009;

[0078] The light transmittance is tested by the method specified in GB / T2410-2008;

[0079] The Shore A hardness is tested by the method specified in GB / T531.1-2009.

[0080] The difference between Comparative Example B1 and Example B1 lies in the structure of the triazine compounds used. It can be seen from Comparative Example B1 and Example B1 that the structure of the triazine compound has an important influence on the tear strength of the polyurethane elastomer, and the triazine compound of the present invention can significantly improve the tear str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com