Zero trans-fatty acid shortening and preparation method thereof

A fatty acid and shortening technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of typical enrichment defects of triglycerides, affecting human health, producing trans fatty acids, etc., and achieving excellent emulsifying performance. , the effect of reducing surface/interfacial tension and improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Auxiliary comprises following steps to make:

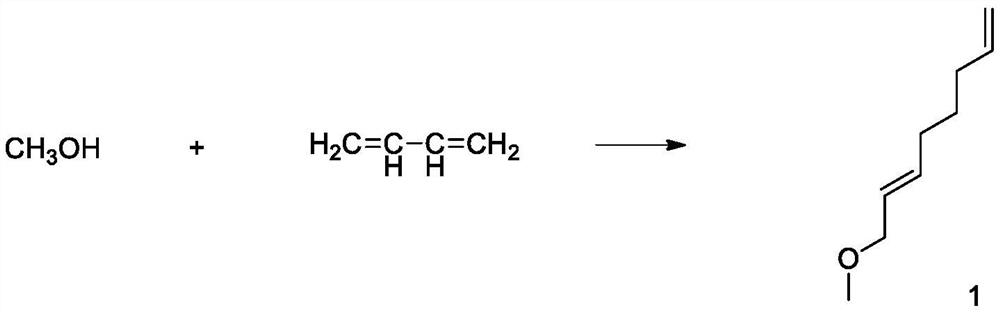

[0028] Step S1, adding methanol, sodium methoxide and tetrakis(triphenylphosphine)palladium into the reaction kettle in sequence, passing nitrogen to replace the air, then adding liquefied butadiene, raising the temperature to 80°C at a constant speed, stirring at a constant speed and reacting for 4 hours to obtain The crude product is taken out, methanol is distilled off, rectified under reduced pressure, and the fraction collected at 9.5kPa and 95°C is intermediate 1, the molar ratio of methanol, sodium methoxide, tetrakis(triphenylphosphine) palladium and butadiene is 2.2:0.075:1.4:1;

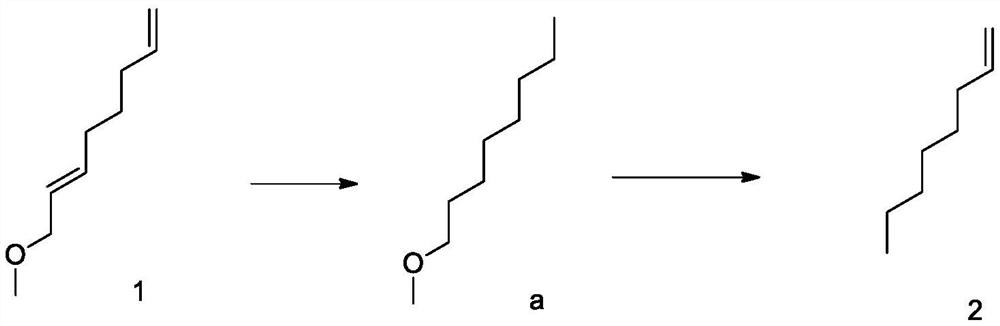

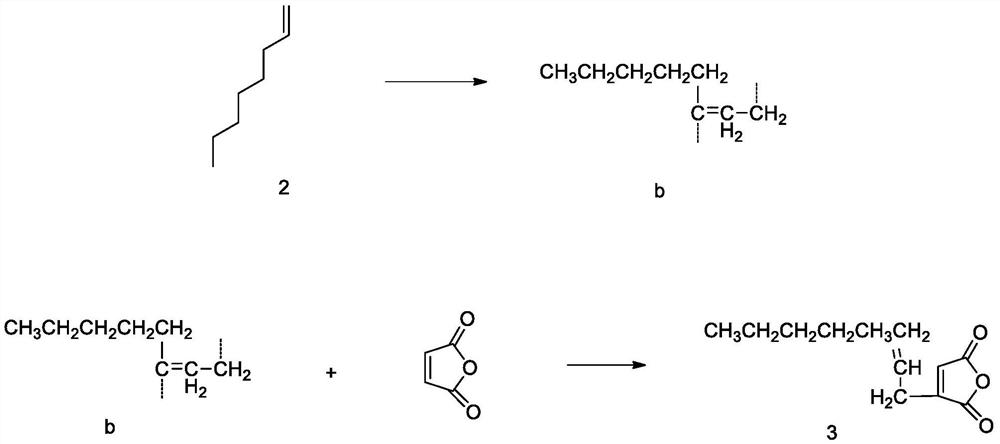

[0029] Step S2, the prepared intermediate 1 and γ-Al 2 o 3 Put it into the reaction kettle, replace it with hydrogen three times, and then pass in argon to make the pressure in the kettle reach 1.5MPa and raise the temperature to 75°C, keep the temperature for reaction at this temperature, and then pass in argon again when the pressure ...

Embodiment 2

[0033] Auxiliary comprises following steps to make:

[0034] Step S1, adding methanol, sodium methoxide and tetrakis(triphenylphosphine)palladium into the reaction kettle in sequence, passing nitrogen to replace the air, then adding liquefied butadiene, raising the temperature to 80°C at a constant speed, stirring at a constant speed and reacting for 4 hours to obtain The crude product is taken out, methanol is distilled off, rectified under reduced pressure, and the fraction collected at 9.5kPa and 95°C is intermediate 1, the molar ratio of methanol, sodium methoxide, tetrakis(triphenylphosphine) palladium and butadiene is 2.3:0.075:1.45:1;

[0035] Step S2, the prepared intermediate 1 and γ-Al 2 o 3 Put it into the reaction kettle, replace it with hydrogen three times, and then pass in argon to make the pressure in the kettle reach 1.5MPa and raise the temperature to 75°C, keep the temperature for reaction at this temperature, and then pass in argon again when the pressure...

Embodiment 3

[0039] Auxiliary comprises following steps to make:

[0040] Step S1, adding methanol, sodium methoxide and tetrakis(triphenylphosphine)palladium into the reaction kettle in sequence, passing nitrogen to replace the air, then adding liquefied butadiene, raising the temperature to 80°C at a constant speed, stirring at a constant speed and reacting for 4 hours to obtain The crude product was taken out, methanol was distilled off, rectified under reduced pressure, and the fractions at 9.5kPa and 100°C were collected.

[0041] That is intermediate 1, the molar ratio of methanol, sodium methoxide, tetrakis(triphenylphosphine) palladium and butadiene is 2.4:0.075:1.48:1;

[0042] Step S2, the prepared intermediate 1 and γ-Al 2 o 3 Put it into the reaction kettle, replace it with hydrogen three times, and then pass it into argon, so that the pressure in the kettle reaches 1.5MPa and raise the temperature to 80°C, and keep it warm at this temperature for reaction. Until the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com