Universal polyester high-ratio foamed bead and preparation method thereof

A technology for foaming beads and polyester, applied in the field of polyester foaming beads, can solve the problems of inability to directly make foamed materials, high crystallinity of polyester, and decreased melt strength, etc. The effect of low bubble temperature and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

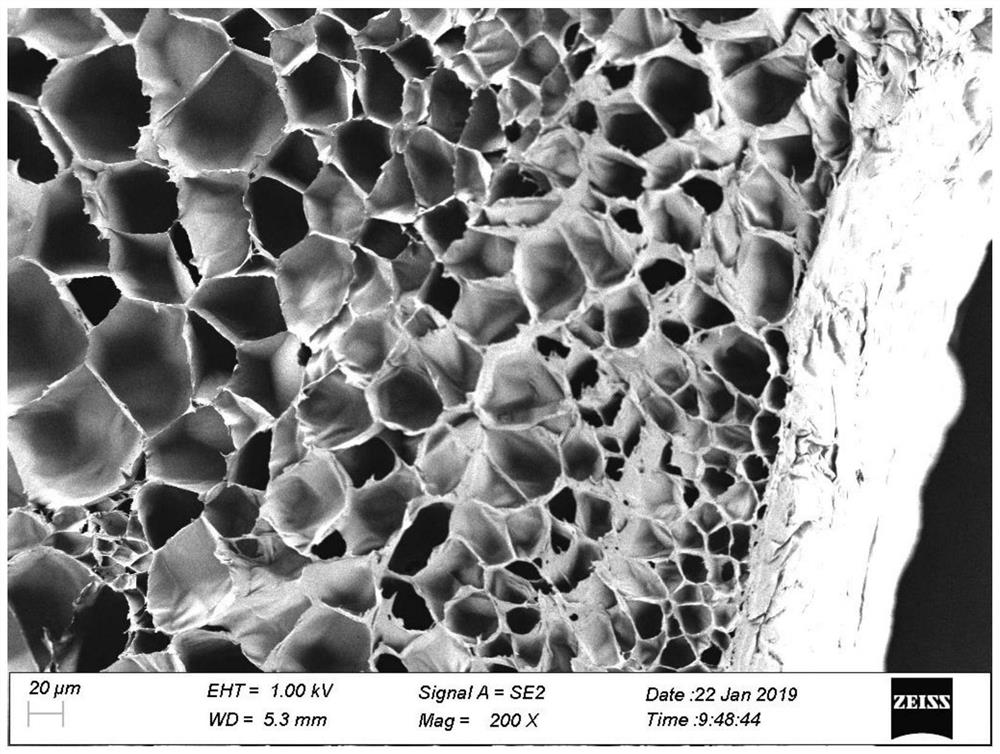

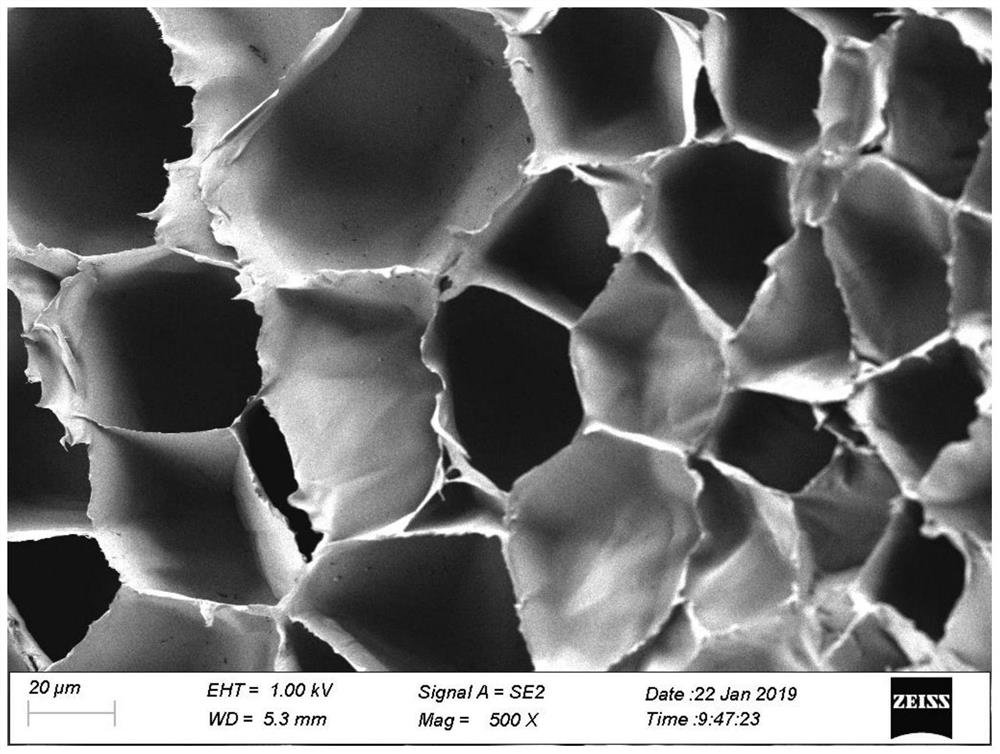

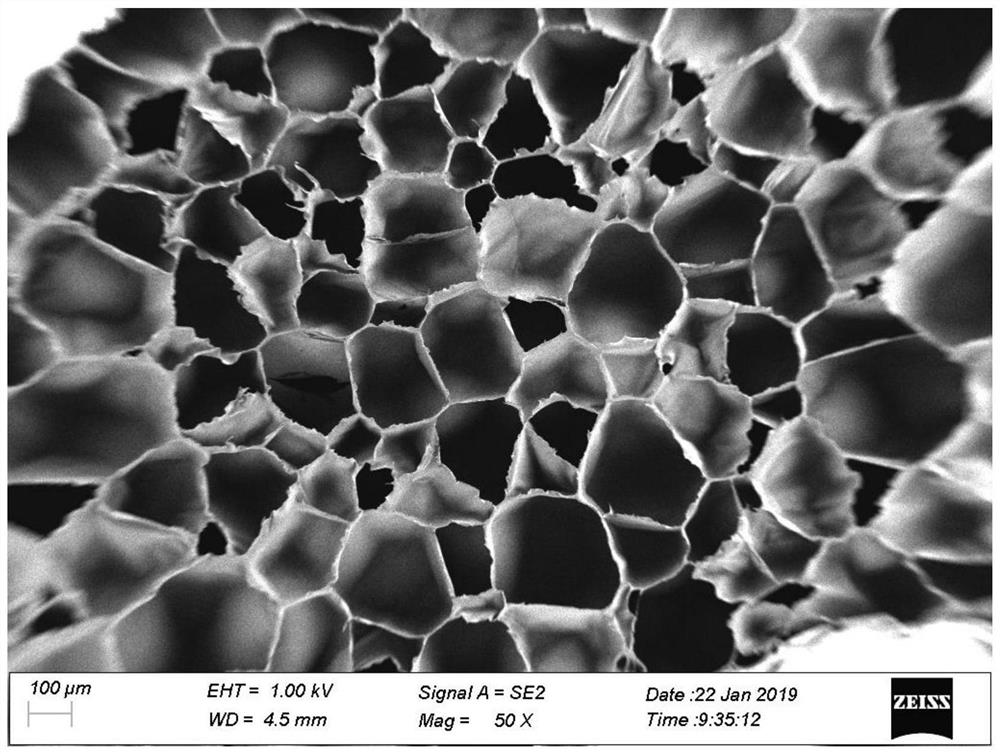

Image

Examples

preparation example Construction

[0067] The invention provides a kind of preparation method of polyester foam beads, comprising the following steps:

[0068] 1) After the polyester resin is extruded and granulated and rapidly cooled, non-crystalline polyester particles are obtained;

[0069] 2) At a certain temperature, the non-crystalline polyester particles obtained in the above steps are placed in the mold cavity, filled with supercritical fluid, and after reaching equilibrium, a polymer-supercritical fluid homogeneous system is obtained;

[0070] 3) Pressure release and foam the polymer-supercritical fluid homogeneous system obtained in the above steps to obtain polyester foam beads.

[0071] In the invention, the polyester resin is extruded, granulated and rapidly cooled to obtain non-crystalline polyester particles.

[0072] In the present invention, the melt index of the polyester resin is preferably 0.5-5 g / 10 min, more preferably 1.5-4 g / 10 min, more preferably 2.5-3 g / 10 min. Wherein, the melt ind...

Embodiment 1

[0108] First, the fiber-grade polyester chips and the chain extender are vacuum-dried at 80°C for more than 4 hours, and the moisture content is controlled below 100ppm.

[0109] Then, it is extruded and granulated through a twin-screw extruder. The feed section of the extruder is 250-260°C, the melting section is 260-265°C, the homogenization section is 265-270°C, and the die is 270°C. During the extrusion melting process, 0.35-0.4% of pyromellitic anhydride (PMDA) is added to control the IV value of the polyester to 1.0-1.2 dL / g. Water-stretched granulation is adopted, the cooling water temperature is lower than 5°C, and the crystallization is suppressed by a rapid cooling process, and the non-crystalline to-be-foamed granules with a particle size of 1 mm are made.

[0110] Next, place the particles to be expanded in a high-pressure container with a constant temperature at T1, replace the air, and fill with supercritical carbon dioxide. The supercritical fluid pressure is 16...

Embodiment 2

[0116] First, using the drying method in Example 1, the bottle-grade polyester chips and the chain extender were dried for later use.

[0117] Next, extrude and granulate by a twin-screw extruder, adopt the extrusion process of Example 1, add 0.15-0.18% triglycidyl isocyanurate (TGIC) during the melting process, and control the IV value of polyester to 0.8 -1.0dL / g. Water-stretched granulation is adopted, the cooling water temperature is lower than 5°C, and the crystallization is suppressed through a rapid cooling process, and the non-crystalline to-be-foamed granules with a particle size of 2 mm are made.

[0118] Next, place the particles to be expanded in a high-pressure container with a constant temperature at T1, replace the air, and fill with supercritical carbon dioxide. The supercritical fluid pressure is 13MPa, the temperature T1 is 120°C, and the swelling and infiltration takes 45 minutes to saturation.

[0119] Then, the pressure in the high-pressure container is q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com