Blast furnace zinc ash recovery and purification process for preparing zinc carbonate

A zinc carbonate and blast furnace technology, applied in zinc compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of waste of resources, low recovery efficiency of zinc oxide, low processing efficiency of zinc carbonate, etc. The effect of cleaner production requirements and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

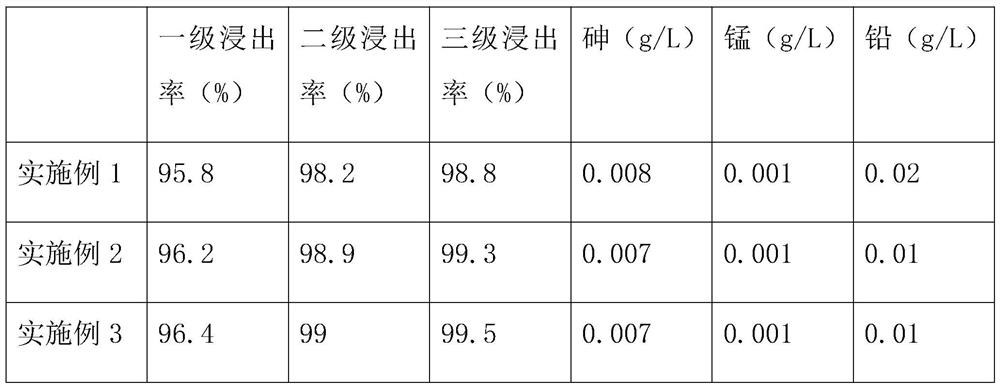

Embodiment 1

[0032] The invention provides a process for recovering and purifying blast furnace zinc soot for preparing zinc carbonate, comprising the following steps:

[0033] Step 1: Primary Leaching

[0034] Lead the blast furnace zinc soot in the zinc carbonate preparation furnace into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for leaching, keep the temperature of the leaching solution at 40°C during the leaching process, control the pH value at the end point to 5.0, and filter after the leaching is completed to obtain Primary leachate and primary leach residue;

[0035] Step 2: Secondary Leaching

[0036] Put the primary leaching residue in step 1 into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for the second stirring leaching, keep the temperature of the leaching solution at 55°C during the leaching process, control the end point pH value to 3.8, and leaching After completion, filter to...

Embodiment 2

[0053] A process for recovering and purifying blast furnace zinc soot for preparing zinc carbonate, comprising the following steps:

[0054] Step 1: Primary Leaching

[0055] Lead the blast furnace zinc soot in the zinc carbonate preparation furnace into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for leaching, keep the temperature of the leaching solution at 45°C during the leaching process, control the pH value at the end point to 5.3, and filter after the leaching is completed to obtain Primary leachate and primary leach residue;

[0056] Step 2: Secondary Leaching

[0057] Put the primary leaching residue in step 1 into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for the second stirring leaching, keep the temperature of the leaching solution at 55°C during the leaching process, control the end point pH value to 4.2, and leaching After completion, filter to obtain secondary leach...

Embodiment 3

[0074] A process for recovering and purifying blast furnace zinc soot for preparing zinc carbonate, comprising the following steps:

[0075] Step 1: Primary Leaching

[0076] Lead the blast furnace zinc soot in the zinc carbonate preparation furnace into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for leaching, keep the temperature of the leaching solution at 50°C during the leaching process, control the pH value at the end point to 5.6, and filter after the leaching is completed to obtain Primary leachate and primary leach residue;

[0077] Step 2: Secondary Leaching

[0078] Put the primary leaching residue in step 1 into the leaching tank, add dilute sulfuric acid leaching agent into the leaching tank and stir for the second stirring leaching, keep the temperature of the leaching solution at 60°C during the leaching process, control the end point pH value to 4.5, and leaching After completion, filter to obtain secondary leach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com