Adsorbent capable of being used for removing endotoxin and inflammatory factors in blood of sepsis patient and preparation method of adsorbent

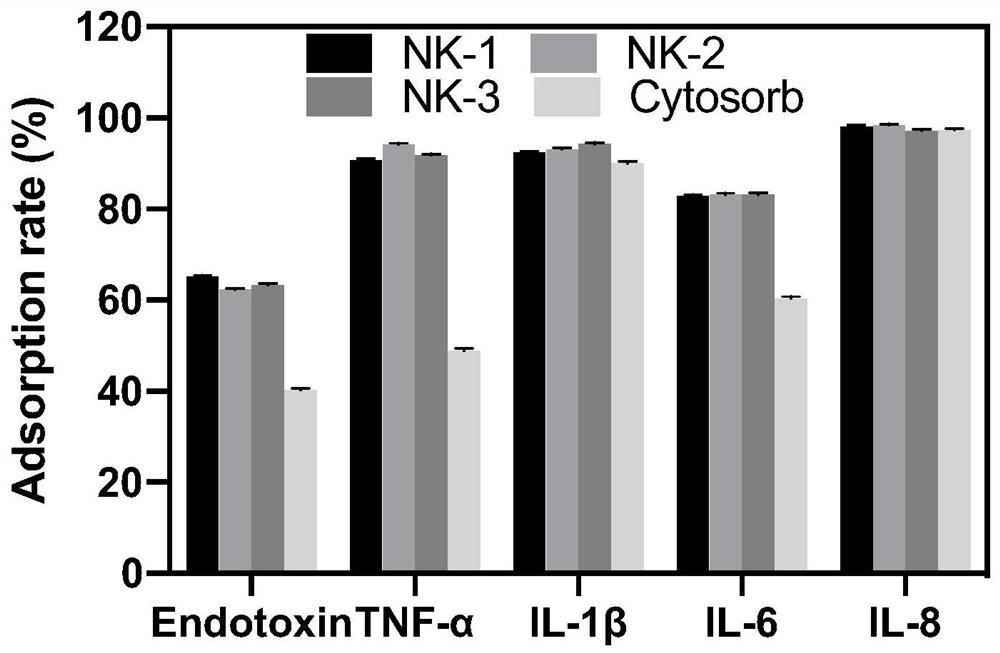

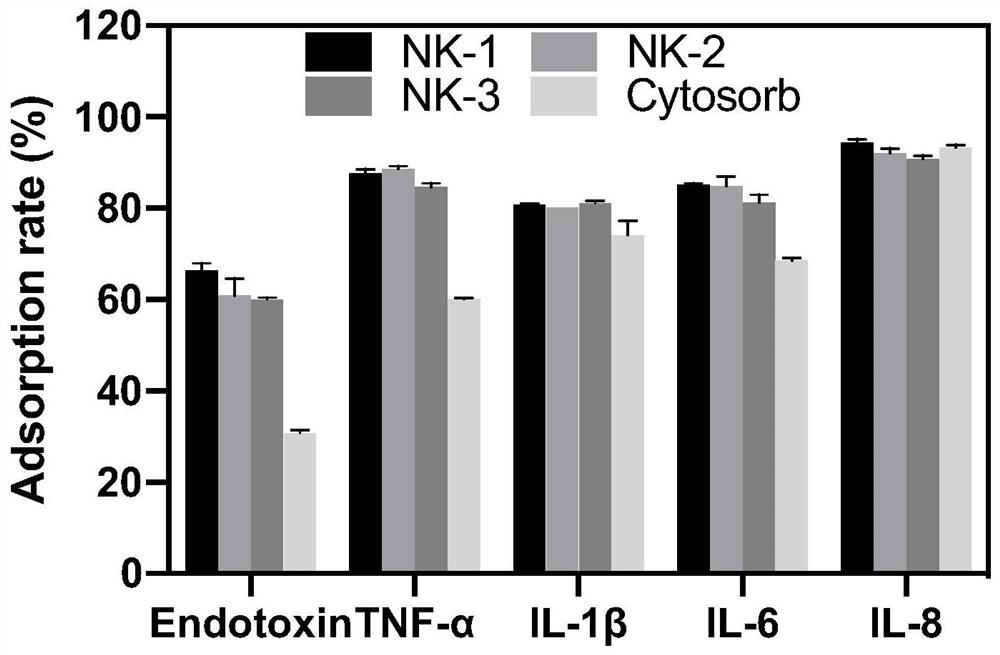

A technology of inflammatory factors and adsorbents, applied in chemical instruments and methods, blood circulation treatment, suction devices, etc., can solve the problems of adsorption performance gap, complicated production process, expensive oXiris, etc., to improve adsorption capacity and adsorption efficiency , the effect of excellent adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a multifunctional nanocomposite structure adsorbent that can be used to remove endotoxins and inflammatory factors in the blood of patients with sepsis, comprising the following steps:

[0029] (a) Preparation of nanocomposite adsorbent carrier: Add 2.0g of nano-calcium carbonate with a particle size of 50-100nm into 20g of styrene and 40g of divinylbenzene in a 500mL beaker, ultrasonicate for 30min with an ultrasonic cell pulverizer, then add 0.6 g of benzoyl peroxide was stirred to dissolve it, and after the dissolution was complete, 20 g of toluene, 20 g of gasoline and 20 g of isopropanol were added thereto, and fully mixed to obtain an organic phase. At room temperature, add 4g of polyvinyl alcohol and 400mL of deionized water into a 2000mL three-neck flask to form a 1.0% (mass fraction) aqueous solution of polyvinyl alcohol, and heat and stir to 45°C to fully dissolve the polyvinyl alcohol to obtain water box. Stop stirring, add the obtaine...

Embodiment 2

[0033] A method for preparing a multifunctional nanocomposite structure adsorbent, comprising the following steps:

[0034] (a) Preparation of nanocomposite adsorbent carrier: Add 2.0g of nano-calcium carbonate with a particle size of 50-100nm into 30g of styrene and 150g of divinylbenzene in a 500mL beaker, ultrasonicate for 30min with an ultrasonic cell disruptor, and then add 1.8 g of benzoyl peroxide was stirred to dissolve it, and after the dissolution was complete, 40 g of toluene, 80 g of n-heptane and 40 g of isopropanol were added thereto, and fully mixed to obtain an organic phase. At room temperature, add 8g of polyvinyl alcohol and 1000mL of deionized water into a 2000mL three-necked flask to form a 0.8% (mass fraction) aqueous solution of polyvinyl alcohol, and heat and stir to 45°C to fully dissolve the polyvinyl alcohol to obtain water box. Stop stirring, add the obtained homogeneously mixed organic phase into the water phase, start the stirrer, adjust the stir...

Embodiment 3

[0038] A method for preparing a multifunctional nanocomposite structure adsorbent, comprising the following steps:

[0039] (a) Preparation of nanocomposite adsorbent carrier: Add 1.0g of nano-calcium carbonate with a particle size of 50-100nm into 20g of styrene and 80g of divinylbenzene in a 500mL beaker. 1.5g of benzoyl peroxide was stirred to dissolve it, and after the dissolution was complete, 80g of toluene, 40g of liquid wax and 80g of isopropanol were added thereto, and fully mixed to obtain an organic phase. At room temperature, add 12g of polyvinyl alcohol and 1000mL of deionized water into a 2000mL three-necked flask to form a 1.2% (mass fraction) aqueous solution of polyvinyl alcohol, and heat and stir to 45°C to fully dissolve the polyvinyl alcohol to obtain Water phase; stop stirring, add the obtained uniformly mixed organic phase into the water phase, start the stirrer, adjust the stirring rate, so that the droplets are evenly distributed, and after the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com