Self-reforming system and method of coke oven gas for blast furnace ironmaking

A technology of coke oven gas and blast furnace ironmaking, which is applied in the field of coal chemical industry, can solve the problems of insufficient heat and low reduction rate of blast furnaces, and achieve the effects of eliminating cracking devices, reducing investment, and making up for heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

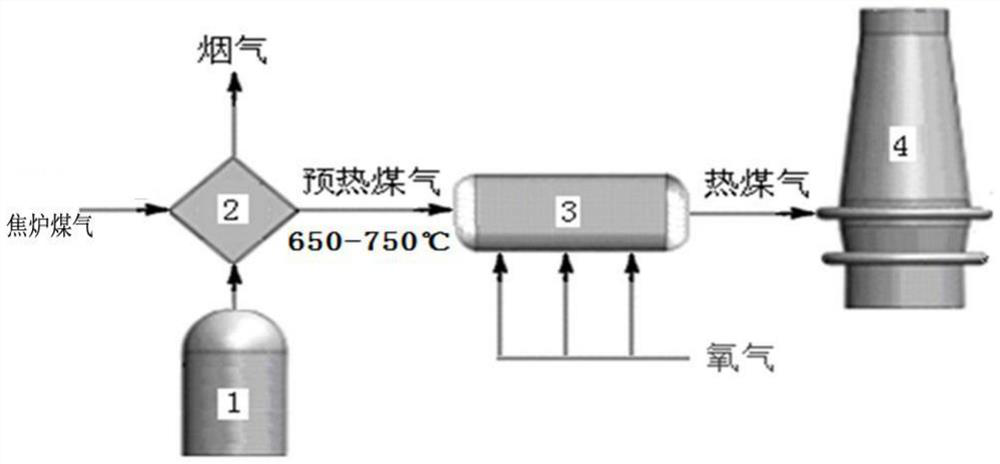

[0027] Such as figure 1 The self-reforming system of coke oven gas for blast furnace ironmaking shown includes a flue gas generator 1, a heat exchanger 2, a coke oven gas self-reforming furnace 3, and a blast furnace 4; wherein, the outlet of flue gas generator 1 is transported by gas The pipeline is connected to the first inlet of the heat exchanger 2, the second inlet of the heat exchanger 2 is connected to the gas pipeline, the outlet of the heat exchanger 2 is connected to the first inlet of the coke oven gas self-reforming furnace 3, and the coke oven gas The second inlet of the self-reforming furnace 3 is connected to the oxygen delivery pipeline, and the outlet of the coke oven gas self-reforming furnace 3 is connected to the blast furnace 4 . The gas pipelines are all lined with heat-insulating and refractory materials.

Embodiment 2

[0029] Coke oven gas self-reforming and used in blast furnace ironmaking

[0030] The remaining room temperature coke oven gas (the composition is shown in Table 1) during the maintenance of tempered co-production ethylene glycol is sent to the PSD type shell and tube metal heat exchanger to preheat to 750°C through the gas delivery pipeline, and then sent to the coke oven gas through the gas delivery pipeline. Furnace gas self-reforming furnace 3, in the coke oven gas self-reforming furnace 3 at 2417Nm 3 / h Oxygen is introduced to reduce CH in coke oven gas 4 , CO 2 Combustion and reforming of water vapor into reducing gases CO and H 2 , sprayed into the blast furnace for ironmaking.

[0031] Draw through factory practical application, use the inventive method to self-reform coke oven gas 17000m 3 / h into 1860m 3 The blast furnace can be used for iron smelting, and the output can be increased by 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com