Novel motor shell welding equipment

A technology for motor housings and welding equipment, applied in welding equipment, welding equipment, laser welding equipment and other directions, can solve the problems of reducing the accuracy of welding, the products are prone to scratches, and the speed of processing is affected, so as to improve the Accuracy, avoid sparks flying upwards, easy to intercept the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

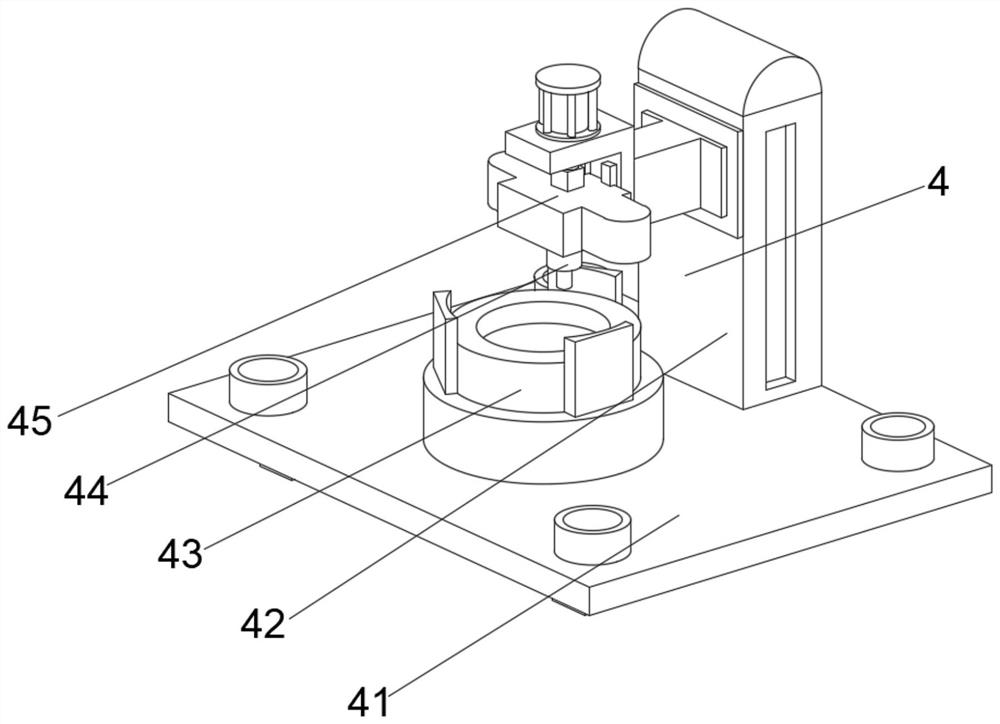

[0033] see Figure 1-2 , the present invention provides a technical solution: a new type of motor shell welding equipment, including a welding main body 1, the front and bottom sides of the welding main body 1 are provided with box doors 2, and the top of the welding main body 1 is fixedly connected with a welding device 4 The two sides of the top of the welding device 4 are fixedly connected with a blocking frame 3, the bottom of the blocking frame 3 runs through the welding device 4 and extends to the inside of the welding device 4, the top of the blocking frame 3 is fixedly connected with a cover plate 5, and the front side of the cover plate 5 The right side is fixedly connected with control panel 6.

[0034] Wherein, the welding device 4 includes a welding platform 41, the top middle position of the welding platform 41 is fixedly connected with a fastening mechanism 43, the surface top middle position of the welding platform 41 is fixedly connected with a column 42, and t...

Embodiment 2

[0037] see Figure 1-4, on the basis of Embodiment 1, the present invention provides a technical solution: Component 1 of the fastening mechanism 43 includes a clamping seat 431, and a rotating column 434 is provided at the middle position of the inner cavity bottom of the clamping seat 431, and the rotating column 434 The top is fixedly connected with a fixer 435, and the bottom of the inner cavity of the clamping seat 431 is located on both sides of the rotating column 434 and is fixedly connected with a lifting positioning plate 432, and a contact body 433 is arranged in the middle of the inner wall of both sides of the lifting positioning plate 432.

[0038] Wherein, the first component of the protective mechanism 45 includes a fixed plate 451, the left outer wall of the fixed plate 451 is fixedly connected with a crossbeam 452, and the position of the crossbeam 452 away from the fixed plate 451 is fixedly connected with a force frame 453, and the top middle position of the...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: component 2 of the fastening mechanism 43 includes a bottom plate d1, and the middle position of the top of the base plate can be fixedly connected with a fastener d5, The middle position of the outer walls on both sides of the fastener d5 is fixedly connected with a support plate d4, and the top of the bottom plate d1 is fixedly connected with an auxiliary positioning frame d2 on both sides of the fastener d5, and the auxiliary positioning frame d2 is close to one side of the fastener d5. The side top is provided with a positioning aid d3.

[0042] Wherein, the second component of the protection mechanism 45 includes a sliding block t1, the outer walls of both sides of the sliding block t1 are provided with a protective frame t2, and the middle position of the inner cavity bottom of the protective frame t2 is provided with a cooler t3, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com