A kind of glass encapsulation method to improve LED light extraction rate

A glass encapsulation and light yield technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor heat resistance and anti-aging properties of epoxy resin or silicone, cost problems, and large difference in refractive index, and achieve Improve LED light output, reduce light leakage, and improve the effect of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

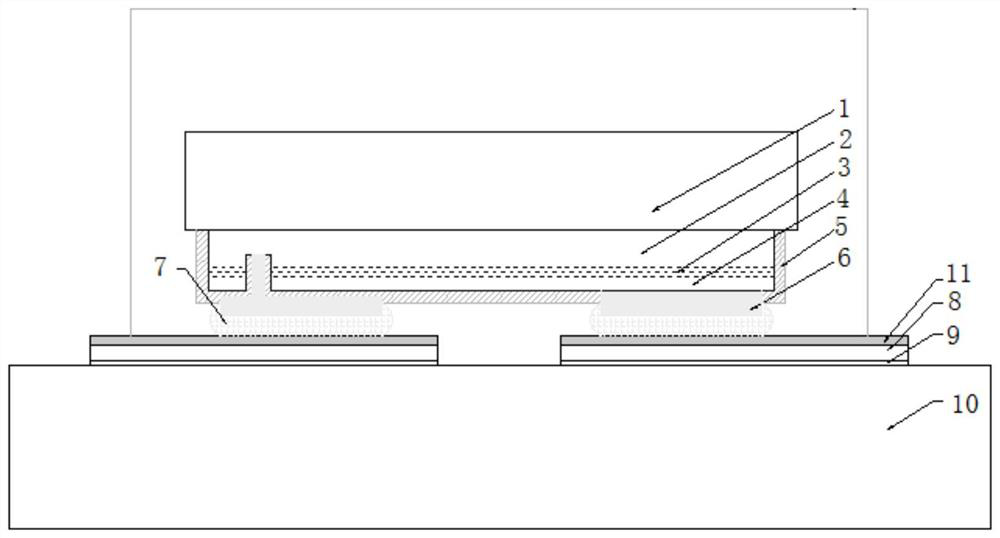

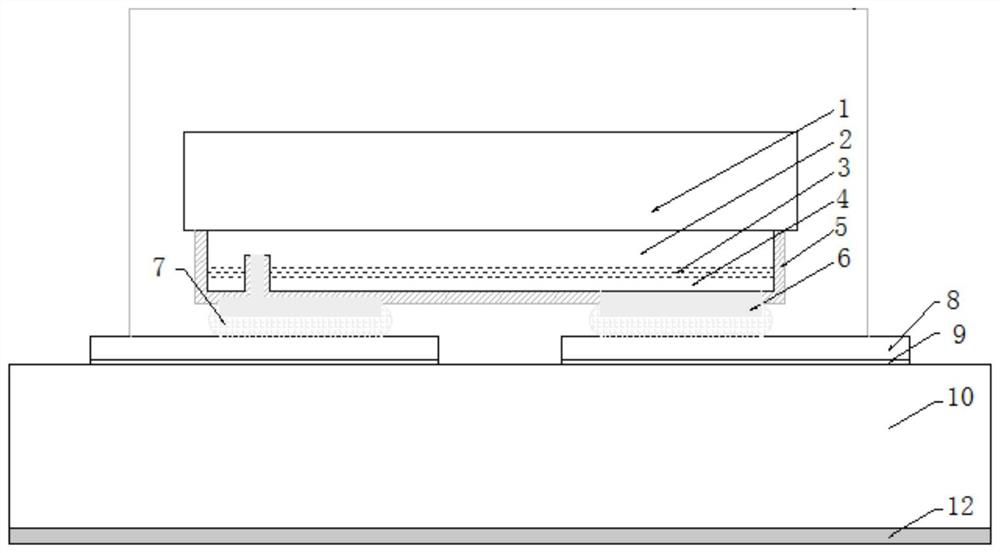

[0035] A glass encapsulation method for improving LED light yield, such as figure 2As shown, the sapphire substrate 1, the gallium nitride layer, the metal conductive layer 8, and the glass substrate 10 are stacked in sequence from top to bottom; wherein, along the direction away from the sapphire substrate 1, the gallium nitride layer includes gallium nitride epitaxial N Type layer 2, GaN epitaxial light-emitting layer 3, GaN epitaxial P-type layer 4; processing the light reflection layer 12 on the back of the glass substrate 10, the specific method is as follows:

[0036] (1) First use polystyrene as a template and ethyl orthosilicate as a raw material to prepare porous silica microspheres, and then mix zirconium oxynitrate hydrate and porous silica microspheres to make a slurry. Solidifying to form a green body, nitriding and sintering to obtain composite microspheres;

[0037] (2) using the composite microspheres and antimony oxide as raw materials to prepare a premix fo...

Embodiment 2

[0053] A glass encapsulation method for improving LED light yield, such as figure 2 As shown, the sapphire substrate 1, the gallium nitride layer, the metal conductive layer 8, and the glass substrate 10 are stacked in sequence from top to bottom; wherein, along the direction away from the sapphire substrate 1, the gallium nitride layer includes gallium nitride epitaxial N Type layer 2, GaN epitaxial light-emitting layer 3, GaN epitaxial P-type layer 4; processing the light reflection layer 12 on the back of the glass substrate 10, the specific method is as follows:

[0054] (1) First use polystyrene as a template and ethyl orthosilicate as a raw material to prepare porous silica microspheres, and then mix zirconium oxynitrate hydrate and porous silica microspheres to make a slurry. Solidifying to form a green body, nitriding and sintering to obtain composite microspheres;

[0055] (2) using the composite microspheres and antimony oxide as raw materials to prepare a premix f...

Embodiment 3

[0071] A glass encapsulation method for improving LED light yield, such as figure 2 As shown, the sapphire substrate 1, the gallium nitride layer, the metal conductive layer 8, and the glass substrate 10 are stacked in sequence from top to bottom; wherein, along the direction away from the sapphire substrate 1, the gallium nitride layer includes gallium nitride epitaxial N Type layer 2, GaN epitaxial light-emitting layer 3, GaN epitaxial P-type layer 4; processing the light reflection layer 12 on the back of the glass substrate 10, the specific method is as follows:

[0072] (1) First use polystyrene as a template and ethyl orthosilicate as a raw material to prepare porous silica microspheres, and then mix zirconium oxynitrate hydrate and porous silica microspheres to make a slurry. Solidifying to form a green body, nitriding and sintering to obtain composite microspheres;

[0073] (2) using the composite microspheres and antimony oxide as raw materials to prepare a premix f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com