Nuclear main pump centering block laser cladding cobalt-based alloy powder welding method

A technology of laser cladding and cobalt-based alloys, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large heat input, prone to pores, and shallow fusion depth, so as to improve the working environment and overcome the efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A laser cladding cobalt-based alloy powder welding method for the centering block of the nuclear main pump:

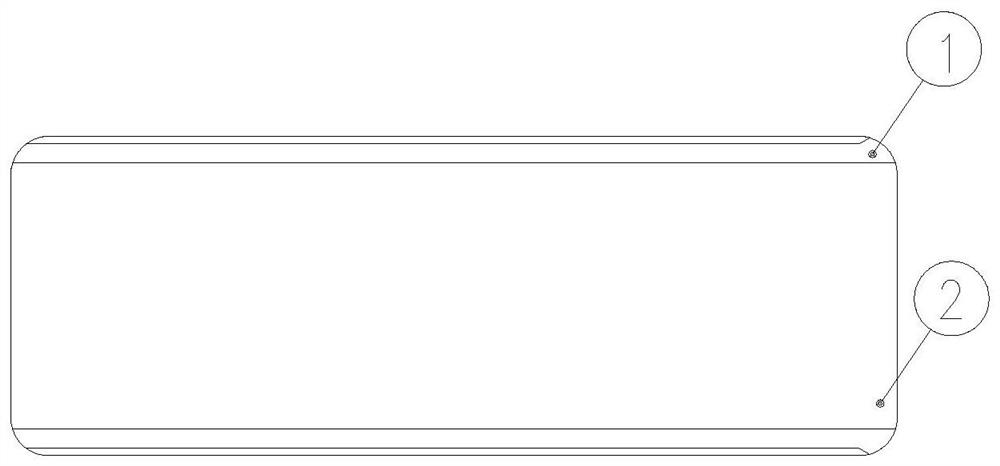

[0022] (1) if figure 1 As shown, the base material of the centering block ① is martensitic stainless steel European standard EN10088-31.4313+QT780. The martensite has been quenched, tempered and tempered. Wipe, remove oil and rust;

[0023] (2) The laser cladding cobalt-based alloy powder used meets the requirements of the AWS 5.21ERCoCr-A standard. In addition, the Fe content should meet 0-2.5%;

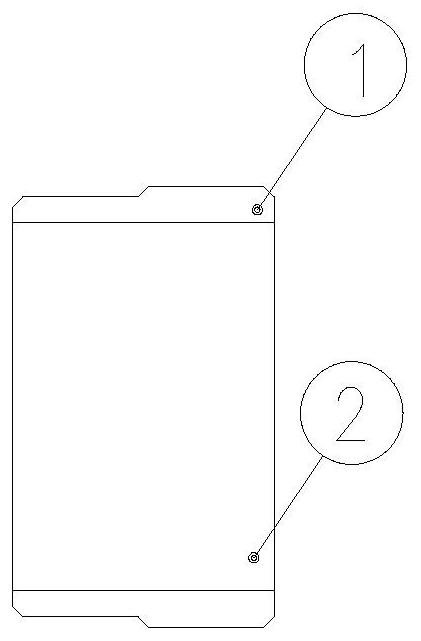

[0024] (3) if figure 2 As shown, the surface of the base material is welded by laser cladding: surfacing ②Thickness: 1.5mm~2.5mm, welding parameters are as follows: Centering block preheating temperature: 310℃, disc laser equipment power: 2.3KW~3.0KW , spot diameter: 35mm~40mm, surfacing welding speed: 580mm / min~630mm / min, protective gas flow rate (Ar): 5L / min~7L / min, powder feeding gas flow rate (He): 3L / min~5L / min , Overlapping amount: 1mm~2mm, number of surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com