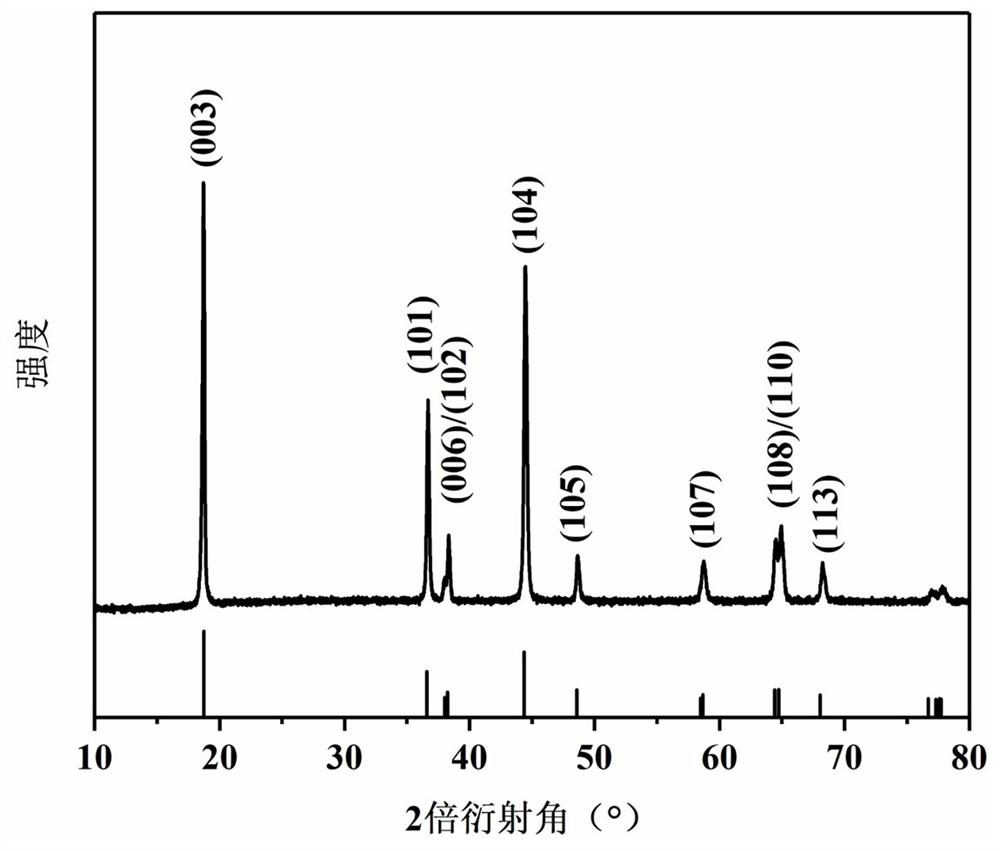

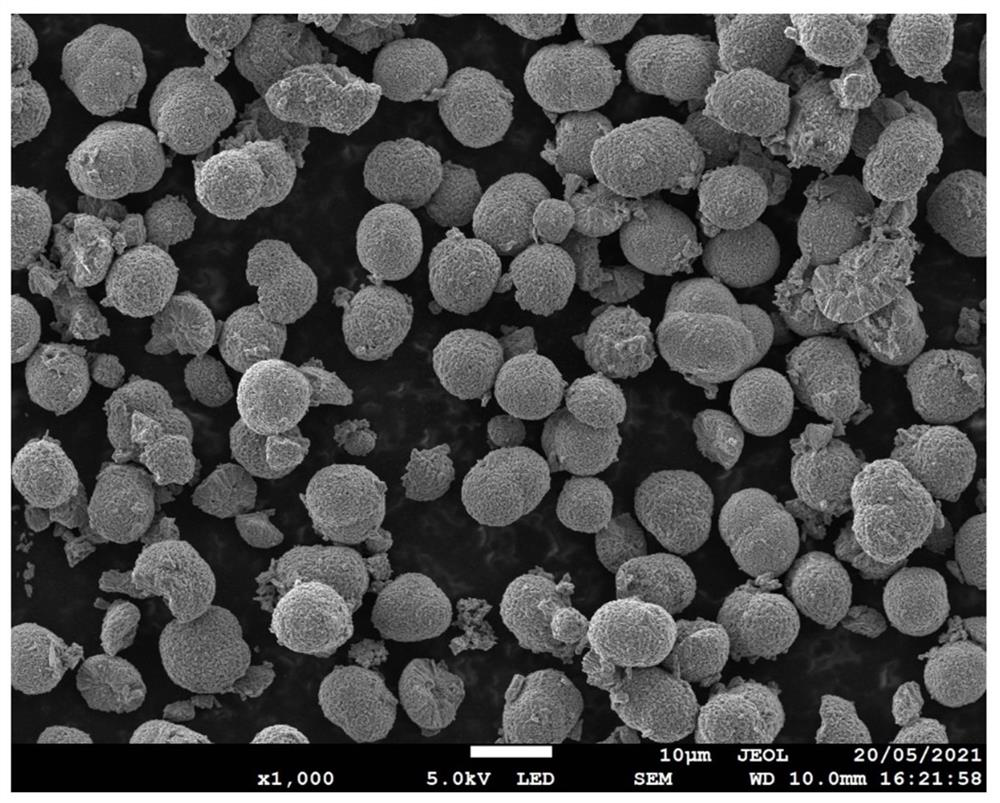

Preparation method of sodium and/or potassium doped high-nickel ternary positive electrode material

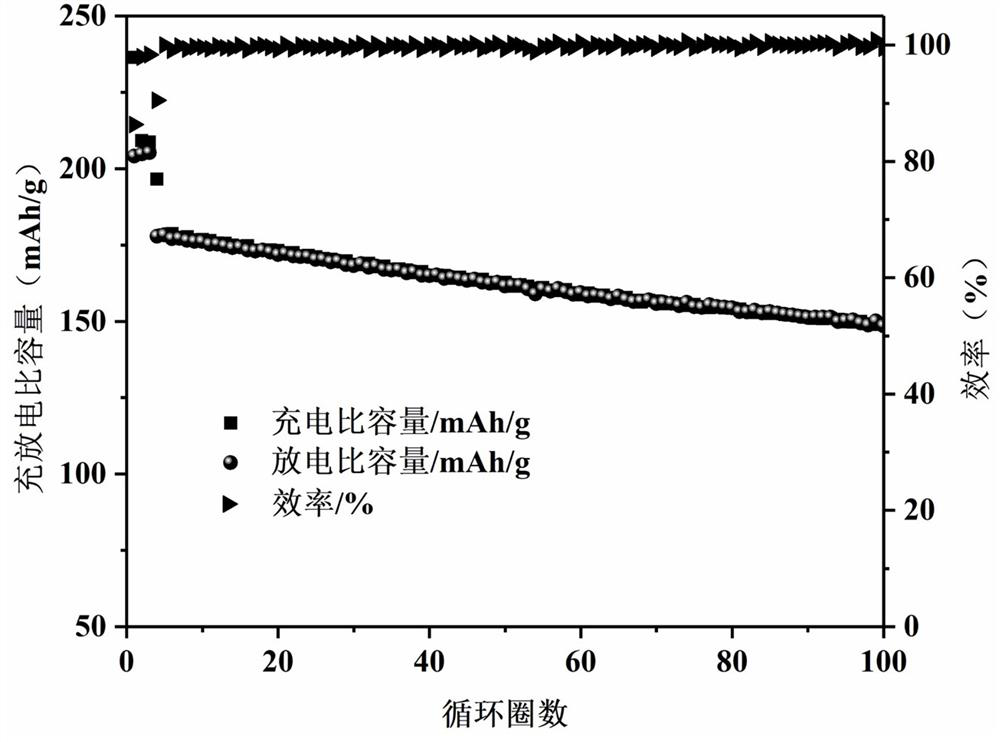

A positive electrode material, potassium doping technology, applied in the field of preparation of high-nickel doped ternary positive electrode materials, can solve the problems of uneven distribution of ternary material particles, unsuitable for industrial applications, difficult to control the crystal growth process, etc., to achieve reduction The generation of irreversible capacity, the improvement of electrochemical performance, and the effect of inhibiting the mixing of lithium and nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a sodium-doped high-nickel ternary positive electrode material, comprising the following steps:

[0038] (1) Weigh 0.0124g (0.310443mmol) NaOH and dissolve it in 20mL deionized water to form solution A; In water, ultrasonically disperse for 1 h to form solution B. Solution A was gradually added to solution B at a flow rate of 100 mL / h, and then stirred at 25 °C for 5 h to form a uniform mixed solution.

[0039] (2) Transfer the homogeneously mixed solution obtained in step (1) into a 100mL polytetrafluoroethylene reactor, then seal it with the corresponding steel shell of the reactor, put it in a blast oven, and heat it at 180°C After being kept at low temperature for 12 hours, it was cooled, filtered, washed, and dried to obtain a doped high-nickel ternary precursor material.

[0040] (3) After mixing 1 g of the doped high-nickel ternary precursor material obtained in step (2) with 0.4558 g (10.8655 mmol) of lithium hydroxide monohydrate, in a ...

Embodiment 2

[0046] A method for preparing a potassium-doped high-nickel ternary positive electrode material, comprising the following steps:

[0047] (1) Weigh 0.0174g (0.310443mmol) KOH and dissolve it in 20mL deionized water to form solution A; In water, ultrasonically disperse for 1.5h to form solution B. Solution A was gradually added to solution B at a flow rate of 120 mL / h, and then stirred at 25 °C for 4 h to form a uniform mixed solution.

[0048] (2) Transfer the homogeneously mixed solution obtained in step (1) into a 100mL polytetrafluoroethylene reactor, then seal it with the corresponding steel shell of the reactor, put it in a blast oven, and heat it at 180°C After being kept at the lower temperature for 14 hours, it was cooled, filtered, washed, and dried to obtain a doped high-nickel ternary precursor material.

[0049] (3) After mixing 1 g of the doped high-nickel ternary precursor material obtained in step (2) with 0.4427 g (10.555 mmol) of lithium hydroxide monohydrat...

Embodiment 3

[0055] A preparation method of a sodium- and potassium-doped high-nickel ternary positive electrode material, comprising the following steps:

[0056] (1) Dissolve 0.0062g (0.15522mmol) NaOH and 0.0087g (0.15522mmol) KOH in 20mL deionized water to form solution A; Mn1.042956mmol) was dissolved in 30mL deionized water, and ultrasonically dispersed for 2h to form solution B. Solution A was gradually added to solution B at a flow rate of 100 mL / h, and then stirred at 25 °C for 6 h to form a uniform mixed solution.

[0057] (2) Transfer the homogeneously mixed solution obtained in step (1) into a 100mL polytetrafluoroethylene reactor, then seal it with the corresponding steel shell of the reactor, put it in a blast oven, and heat it at 180°C After being kept at low temperature for 12 hours, it was cooled, filtered, washed, and dried to obtain a doped high-nickel ternary precursor material.

[0058] (3) After mixing 1g of the doped high-nickel ternary precursor material obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com