A preparation method of core-shell titanium dioxide@carboxychitosan nanoparticles

A carboxyl chitosan, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of easy recombination of electrons and holes, affecting the service life of the substrate, affecting the photocatalytic effect, etc. to avoid hydrolysis and agglomeration, improve reaction efficiency and uniformity, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

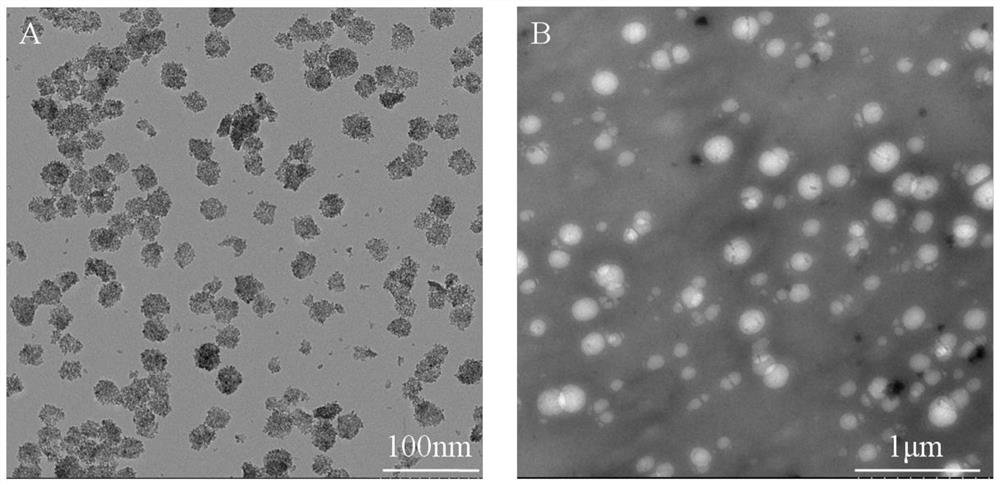

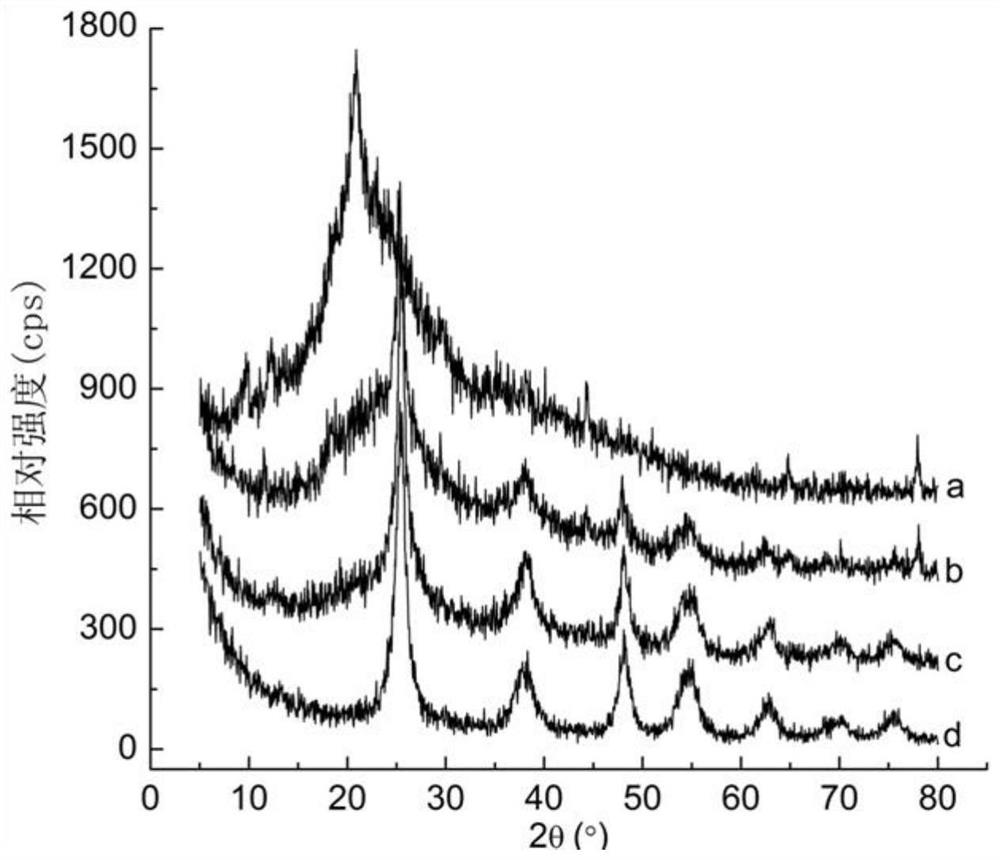

[0037] In this example, core-shell titanium dioxide@carboxychitosan nanoparticles were prepared according to the following steps:

[0038] (1) Under strong stirring, add 1mL tetrabutyl titanate dropwise to 10mL ionic liquid 1-ethyl-3-methylimidazole acetate within 5min at a constant speed, react at room temperature for 0.5h, and add 2mL dropwise at a constant speed within 5min. Ionized water, reacted at 40°C for 4 hours, added 20mL of absolute ethanol, stirred evenly, centrifuged three times at high speed, discarded the supernatant, sonicated three times with 50% ethanol, filtered, and dried in vacuum at 40°C to obtain anatase nano-titanium dioxide.

[0039] (2) Take 0.025g of titanium dioxide prepared in the above step (1) and disperse it in 50mL of 2% acetic acid (v / v) solution, add 1mmol CTAB, stir vigorously for 30min, put it into a reaction kettle, place it in a microwave reactor, and ℃ for 20 minutes to prepare a cation-modified titanium dioxide dispersion. The power of...

Embodiment 2

[0043] In this example, core-shell titanium dioxide@carboxychitosan nanoparticles were prepared according to the following steps:

[0044] (1) Under strong stirring, add 2.5mL tetrabutyl titanate dropwise to 15mL ionic liquid 1-ethyl-3-methylimidazole acetate within 10min at a constant speed, react at room temperature for 1h, and add 5mL dropwise at a constant speed within 10min to remove Ionized water, reacted at 45°C for 5 hours, added 30mL of absolute ethanol, stirred evenly, centrifuged at high speed for 3 times, discarded the supernatant, ultrasonicated 50% (v / v) ethanol three times, filtered, and dried in vacuum at 40°C to obtain anatase type nano titanium dioxide.

[0045] (2) Take 0.05g of titanium dioxide prepared in the above step (1) and disperse it in 50mL of 2% acetic acid (v / v) solution, add 3mmol CTAB, stir vigorously for 30min, put it into a reaction kettle, place it in a microwave reactor, and ℃ for 30 minutes to prepare a cation-modified titanium dioxide dis...

Embodiment 3

[0049] In this example, core-shell titanium dioxide@carboxychitosan nanoparticles were prepared according to the following steps:

[0050] (1) Under strong stirring, add 5 mL of tetrabutyl titanate to 20 mL of ionic liquid 1-ethyl-3-methylimidazole acetate at a constant speed within 15 minutes, react at room temperature for 1.5 hours, and add 8 mL at a constant speed within 20 minutes to remove Ionized water, reacted at 50°C for 6h, added 40mL of absolute ethanol, stirred evenly, centrifuged at high speed for 3 times, discarded the supernatant, ultrasonicated 50% (v / v) ethanol for three times, filtered, and dried in vacuum at 40°C to obtain anatase Nano titanium dioxide.

[0051] (2) Take 0.10 g of titanium dioxide prepared in the above step (1) and disperse it in 50 mL of 2% acetic acid (v / v) solution, add 6 mmol of CTAB, stir vigorously for 30 min, put it into a reaction kettle, place it in a microwave reactor, and ℃ for 50 minutes to prepare a cation-modified titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com